High specific energy super copacitor for vehicle

A supercapacitor, high-ratio technology, applied in the field of capacitors, can solve problems such as reducing battery life and battery damage, and achieve the effects of improving energy density, increasing specific energy, and improving electrochemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

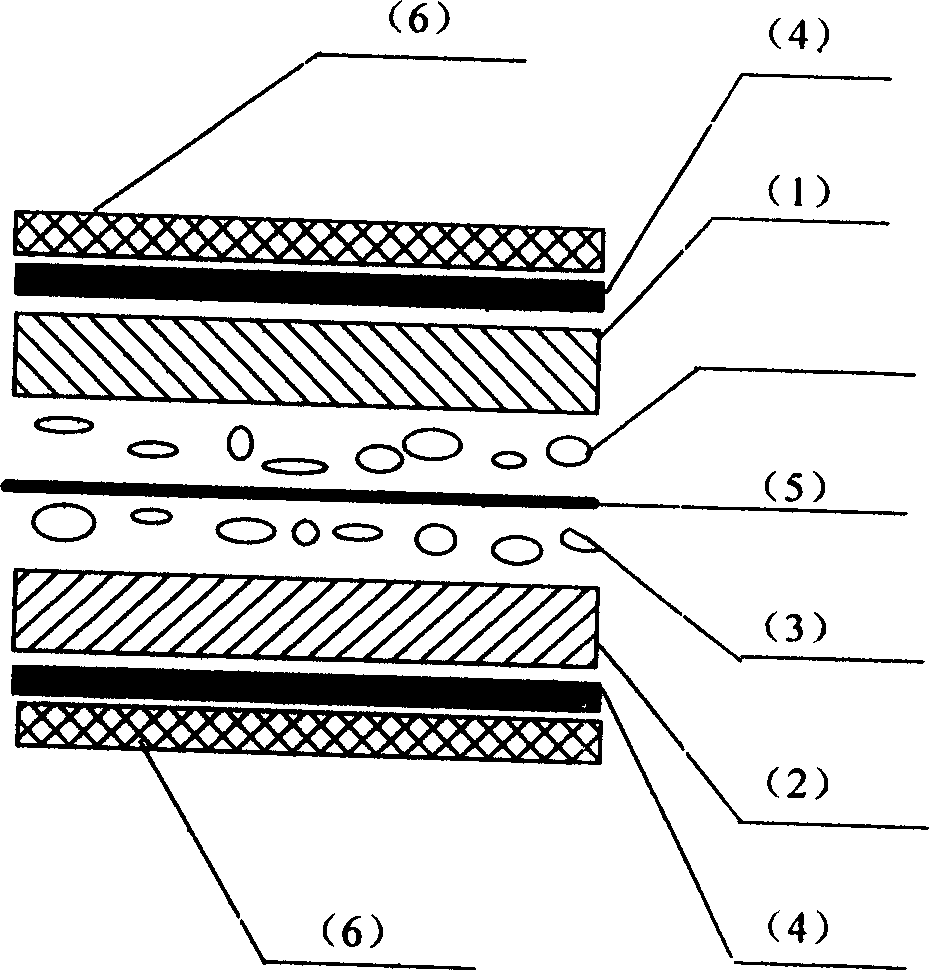

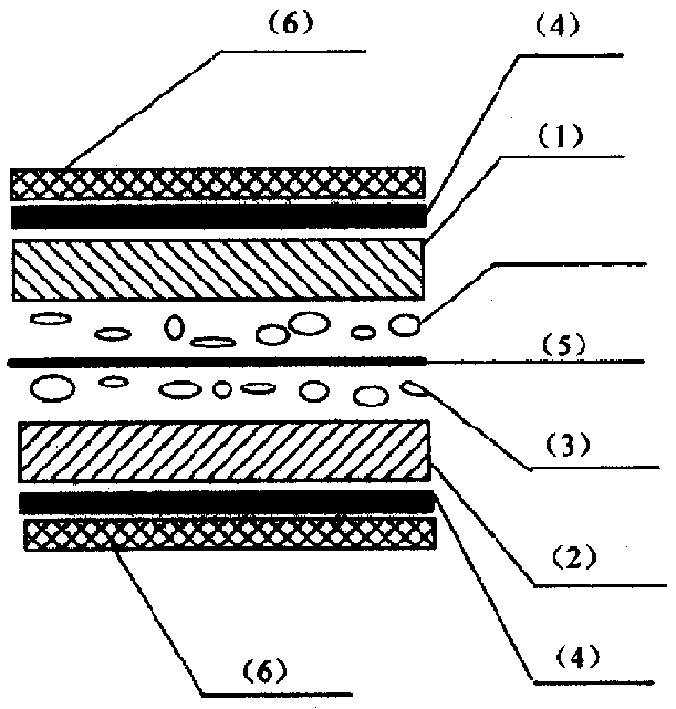

Image

Examples

Embodiment 1

[0026] The negative electrode is made of activated carbon, lithium cobalt oxide (LiCoO 2 ) made of positive electrode, LiPF 6 / EC+DMC is used as the electrolyte, and the electrode formula is shown in Table 1. As a comparison, the relevant data of capacitors with symmetrical electrode structures using activated carbon as positive and negative electrodes are also given.

[0027] The capacity of activated carbon is generally 30-35mAh / g, LiCoO 2 The lowest capacity can reach 140mAh / g, LiCoO 2 The specific capacity of the activated carbon is about 4 to 5 times higher than the specific capacity of the activated carbon, so a capacitor unit with a higher capacity can be obtained under the same geometric size, and the weight of the capacitor is much lower than that of the activated carbon / activated carbon structure. , so this capacitor unit has a higher specific capacity and higher specific energy.

[0028] The performance indicators of the capacitor unit are shown in Table 2.

Embodiment 2

[0030] The negative electrode is made of activated carbon, lithium nickelate (LiNiO 2 ) to make positive electrode, tetrabutylammonium fluoroborate (Eu 4 NBF 4 ) / PC+EC as electrolyte. The electrode formulation is shown in Table 1.

[0031] With embodiment 1, the capacity of gac is 30-35mAh / g, LiNiO 2 The capacity can reach 140~170mAh / g, LiNiO 2 The specific capacity of activated carbon is 4-6 times higher than that of activated carbon, so the capacitor unit has higher specific capacity and specific energy under the same conditions. The performance indicators of the capacitor unit are shown in Table 2.

Embodiment 3

[0033] The difference between this example and the capacitors described in Example 1 and Example 2 is that the electrode made of activated carbon is used as the positive electrode, and the negative electrode is made of a self-made nano-scale intercalation compound such as tungsten oxide. The electrolyte is the same as in Example 1 or Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com