Protective circuit of automation for semiconductor factory

A technology for protecting circuits and semiconductors, applied in the fields of circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as damage to the production machine equipment crystal boat, increased cost, and incorrect operation of the production machine and automatic arm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

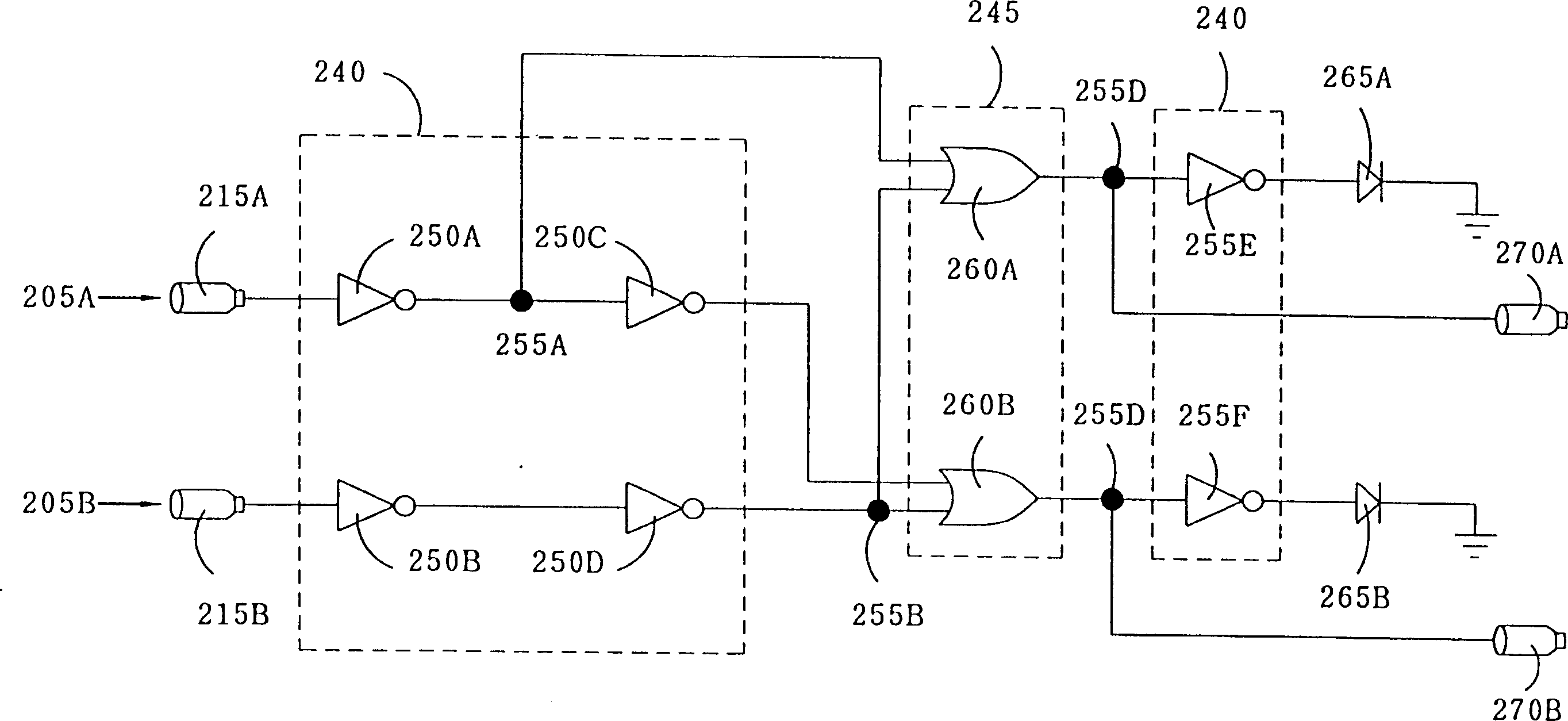

[0015] The direction of the present invention discussed here is a protection circuit between a standard mechanical interface and a manufacturing machine. In order to provide a thorough understanding of the present invention, detailed steps will be set forth in the following description. Obviously, the practice of the invention is not limited to specific details familiar to those skilled in the art of semiconductor components. On the other hand, well-known manufacturing steps or mechanical devices have not been described in detail in order not to unnecessarily limit the present invention. The preferred embodiments of the present invention will be described in detail as follows, but in addition to these detailed descriptions, the present invention can also be widely implemented in other embodiments, and the scope of the present invention is not limited by them, but by the claims .

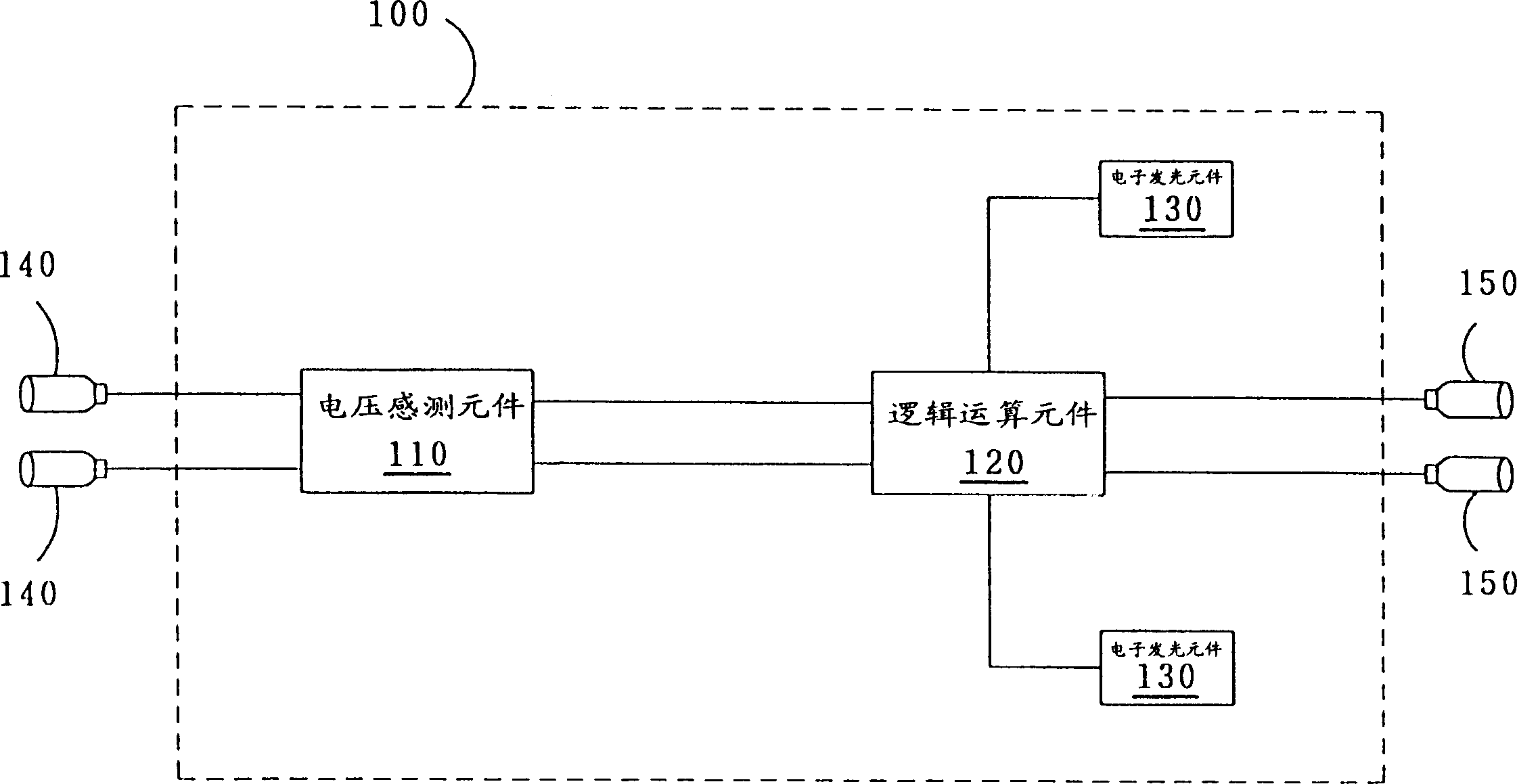

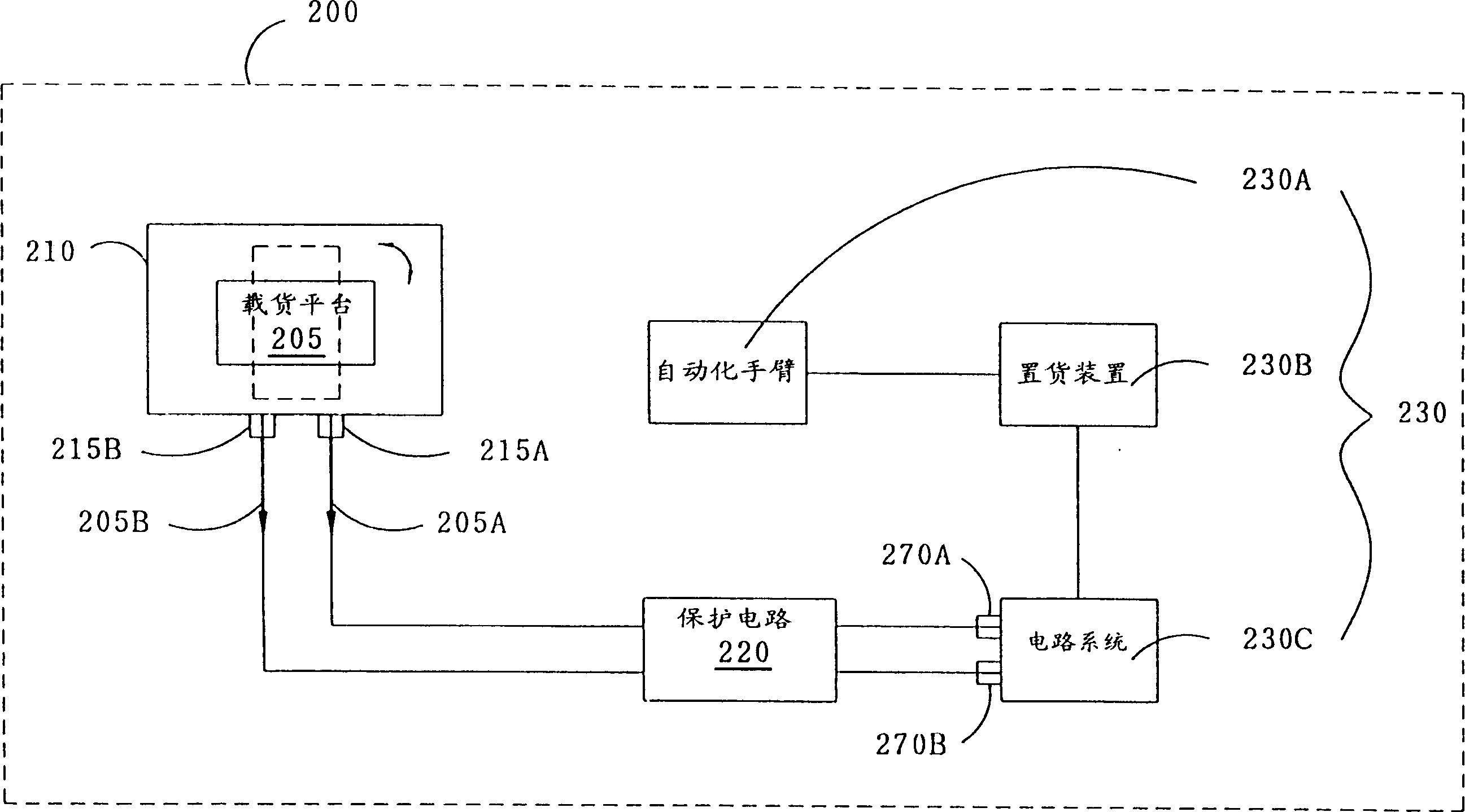

[0016] refer to figure 1 As shown, in the first embodiment of the present invention, a protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com