Humped automatic speed regulating system and method capable of controlling retarder by using access and speed information

A technology of speed information and automatic speed regulation, which is applied to the railway braking system, the operating mechanism of the railway vehicle brake, the track brake, etc., can solve the problems of equipment waste and equipment accumulation, save engineering investment, ensure operation safety, reduce The effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

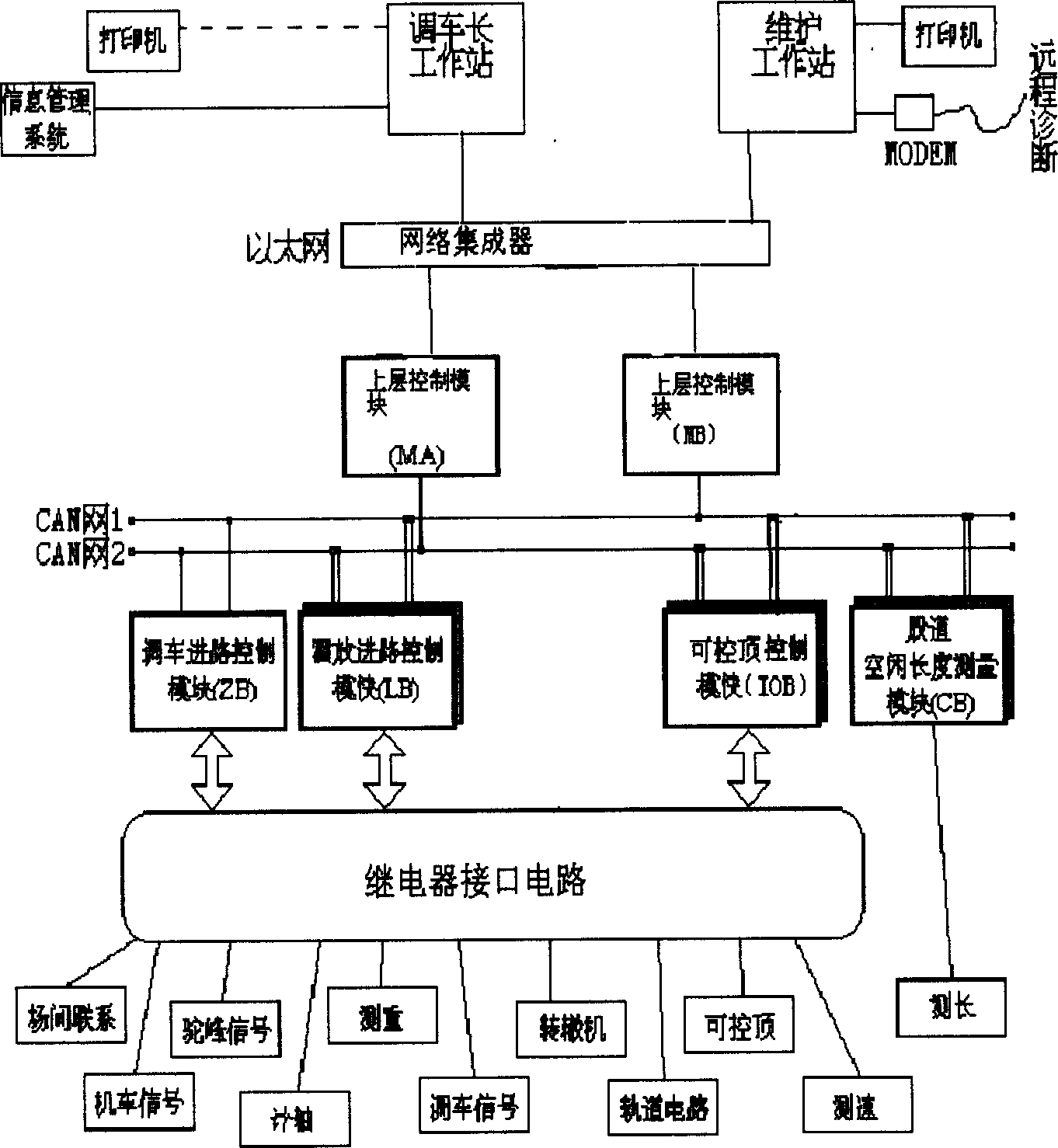

[0042] A control system and method for automatic speed regulation of a hump using a controllable deceleration jack of the route and speed control of the present invention is realized through the following technical scheme, and the system includes:

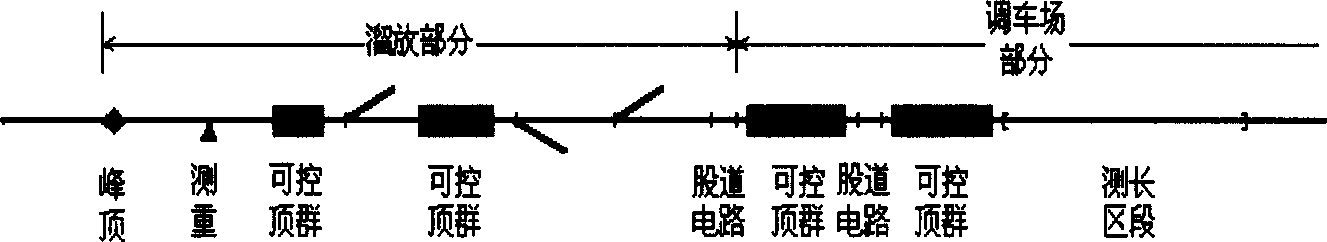

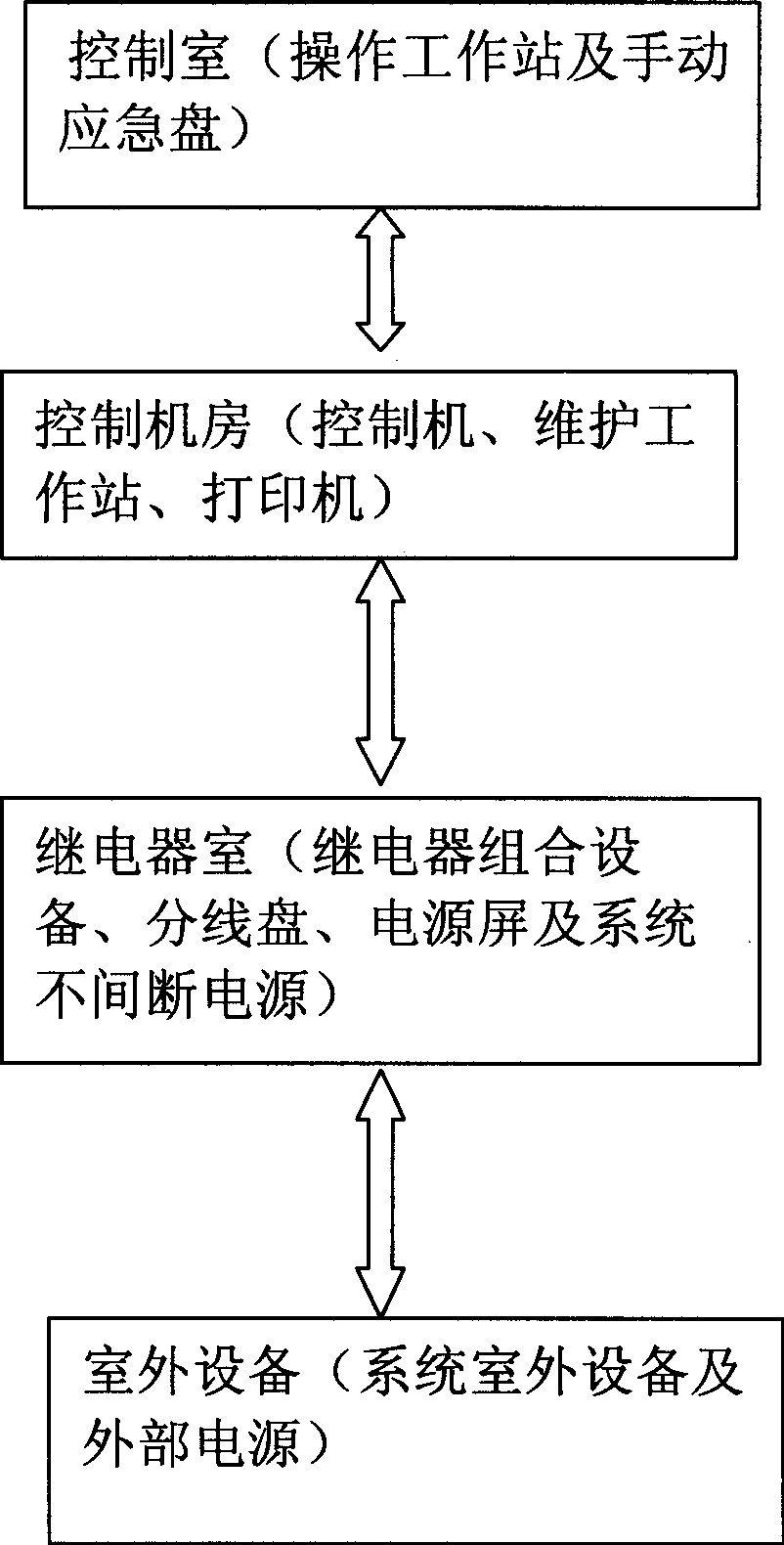

[0043]Outdoor equipment and indoor equipment; the wiring board between outdoor equipment and indoor equipment is connected. The outdoor equipment includes the sliding part and the shunting yard part. The sliding part includes weighing, pedals, controllable deceleration top groups, track circuits, and turnouts. , signal equipment, etc.; the shunting yard part includes the speed measuring track circuit, the controllable deceleration top group, the length measuring section, other track circuits and signal equipment; it can realize the automatic control of the speed and route of the hook car; The indoor equipment includes: a controller whose working mode is dual-machine hot standby, the two hosts can be switched automatically without af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com