Multi-layer electret with ultra-high charge stability and mfg. method thereof

An electret, stability technology, applied in the field of multi-layer electret and its manufacturing, can solve the problem of being easily affected by moisture or the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

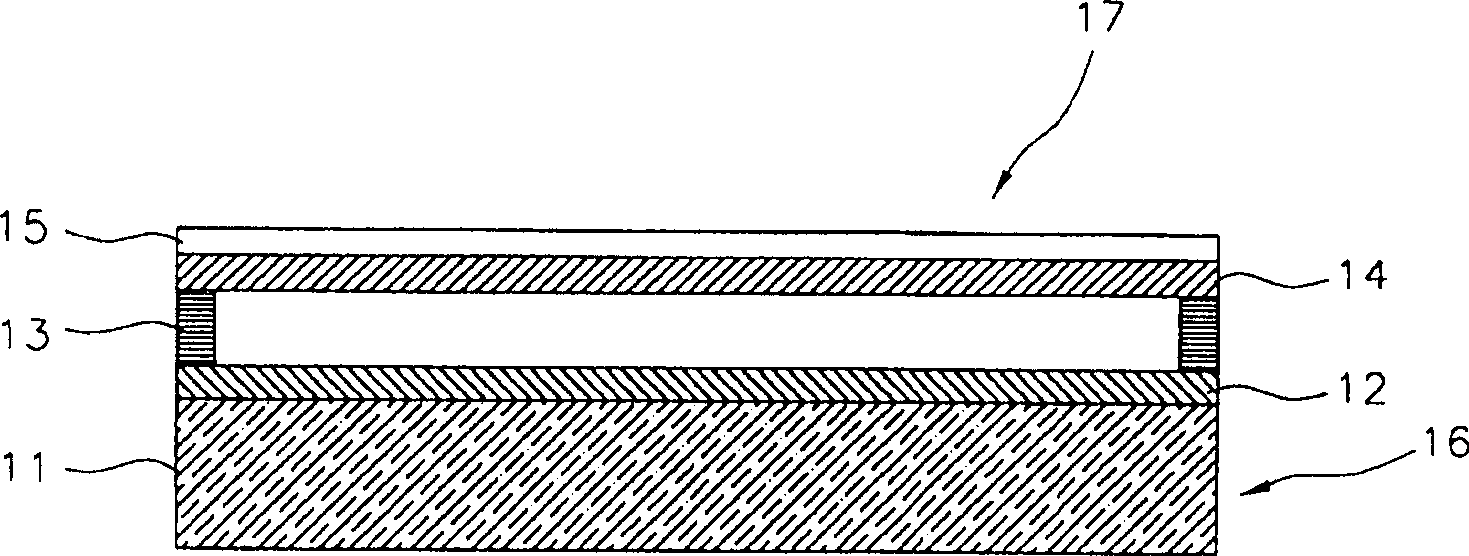

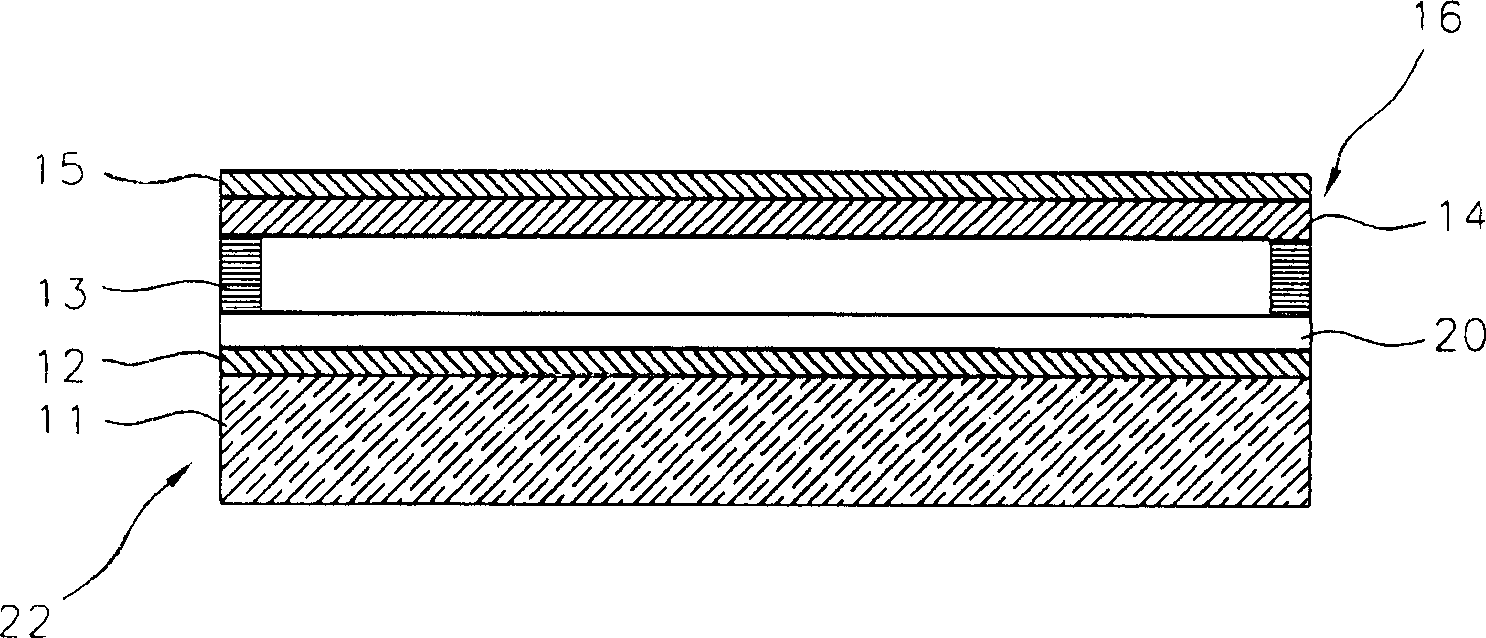

[0017] Now, the present invention will be described with reference to the preferred embodiments of the accompanying drawings.

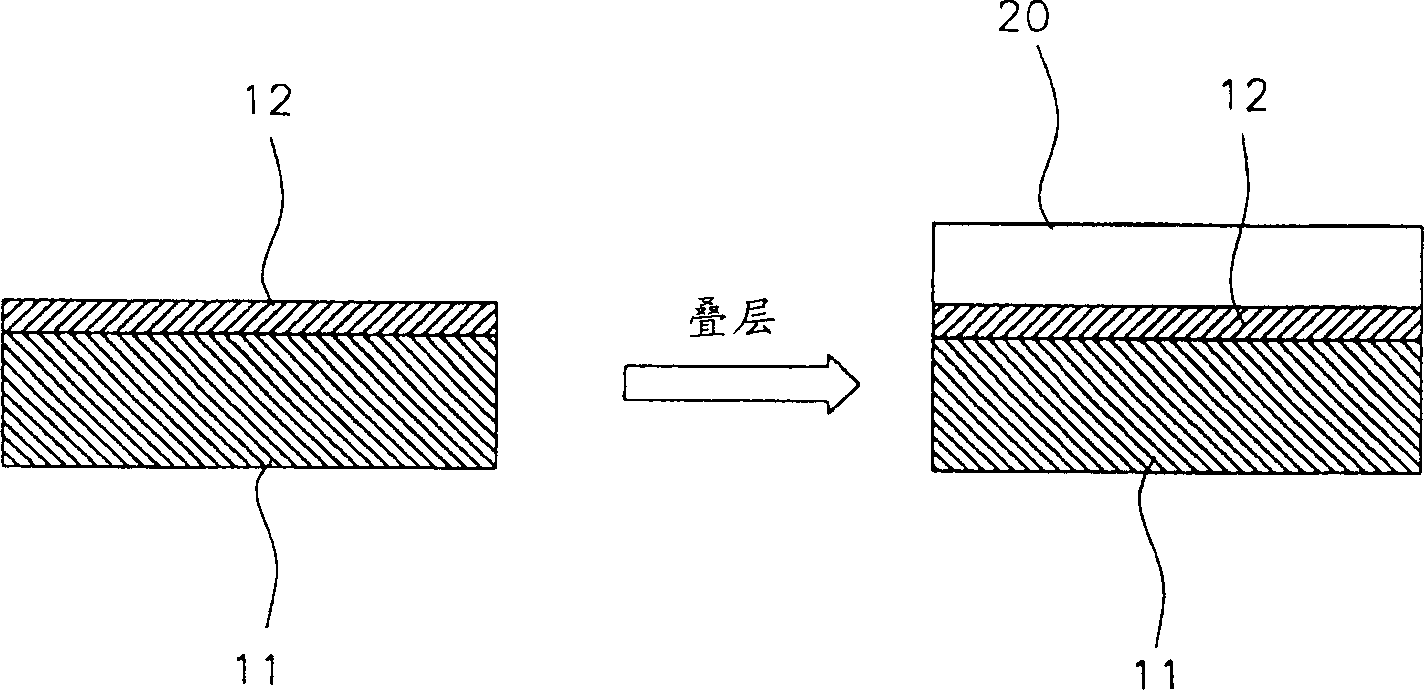

[0018] refer to figure 2 , the polymer electret with ultra-high charging stability according to the present invention is manufactured in such a way that a 12.5 μm-25 μm thick FEP film 12 is bonded on a metal sheet 11 and has a high crystallinity of 30 μm- A 100 μm thick polytetrafluoroethylene (hereinafter referred to as PTFE) film 20 is laminated on the FEP film 12 . Thus, a multilayer electret is constructed.

[0019] Electrets made of FEP film and PTFE film can be processed by SMT because of their high crystallinity. PTFE membranes are formed by a process generally different from the manufacturing method of FEP membranes.

[0020] FEP film is difficult to form with high crystallinity because it is formed by melt extrusion. Even if it has high crystallinity, one grain thereof becomes large so that fine grains cannot be formed on the entire film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com