Solid-state imaging device and its mfg. method

A solid-state imaging device, solid-state technology, applied in radiation control devices, semiconductor/solid-state device parts, installations, etc., can solve the problems of production decline, hinder production improvement, and easy cracking of solid-state imaging components, and achieve connection failure. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

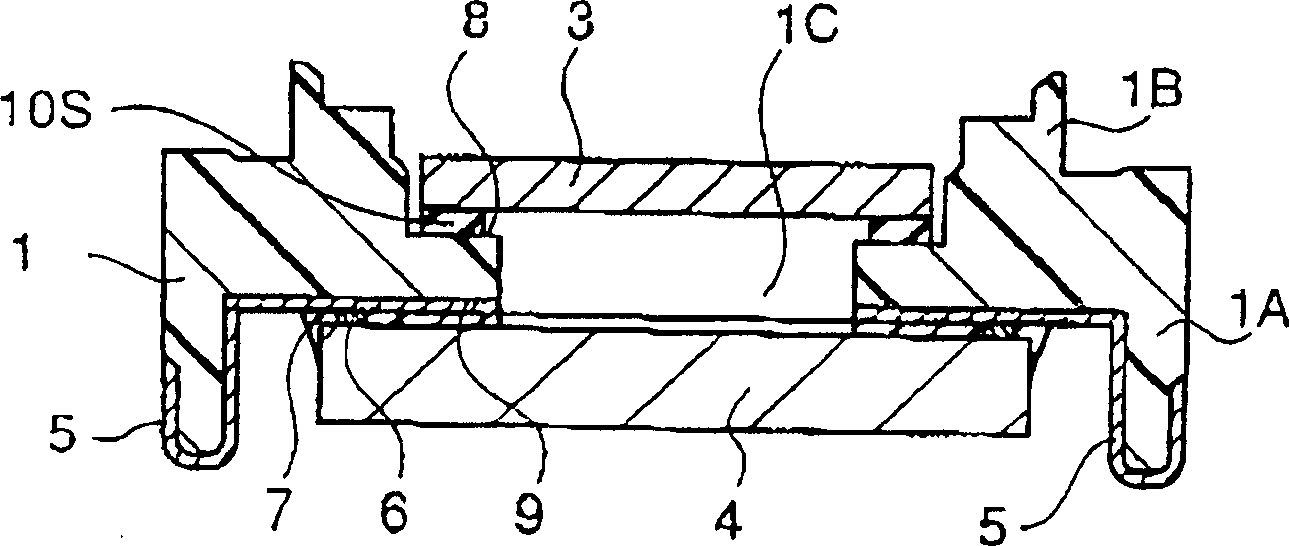

[0108] figure 1 is a view of the main body portion of the solid-state imaging device of the first embodiment of the present invention.

[0109] In the solid-state imaging device of the first embodiment, when the solid-state imaging element 4 is connected to the resin structural member 1 having the wiring portion, the structural member 1 is formed such that the optical filter 3 passes through a ceramic plate having a thermal expansion coefficient smaller than that of the resin structural member 1 10S and connected to the filter mounting surface 8 of the resin structure 1.

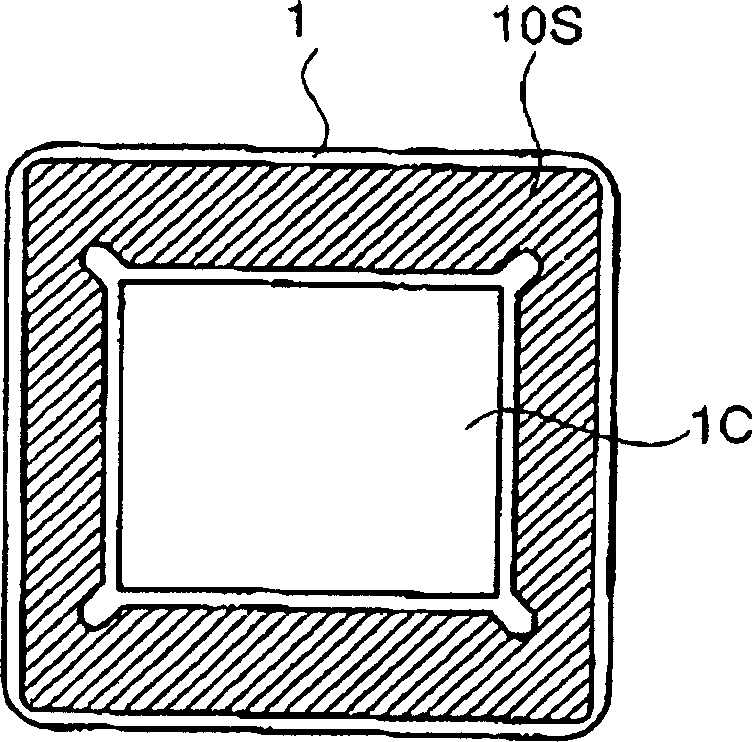

[0110] Such as figure 2 As shown, a ceramic plate 10S is used as a fixing member having a rectangular ring shape with a thickness of about t=0.1-0.2 mm and a coefficient of thermal expansion of about 10 ppm / °C. The ceramic plate is composed of insulating polyphthalamide resin. The image forming apparatus includes: a resin structural member 1 comprising, a leg portion 1A having a rectangular truncated sha...

Embodiment 2

[0122] Below, refer to Figure 5 A second embodiment of the present invention will be described.

[0123] In the solid-state imaging device of the second embodiment, the structural member 1 is integrally molded, and the metal plate 10M is sandwiched in the resin structural member 1 . In this embodiment, the structural member 1 is integrally molded and the metal plate 10M is clamped in the structural member 1. The surfaces of the metal plate 10M are in contact.

[0124] In solid-state imaging devices such as Figure 5 As shown, a metal plate 10M having a rectangular ring shape is integrally molded between the filter mounting surface 8 and the solid-state image pickup element mounting surface 9 of the resin structural member 1 having a wiring portion made of thermoplastic PPS resin in parallel Because of these surfaces, deformation of the solid-state imaging element mounting surface 9 is suppressed.

[0125] Other parts are formed in the same manner as the first embodiment. ...

Embodiment 3

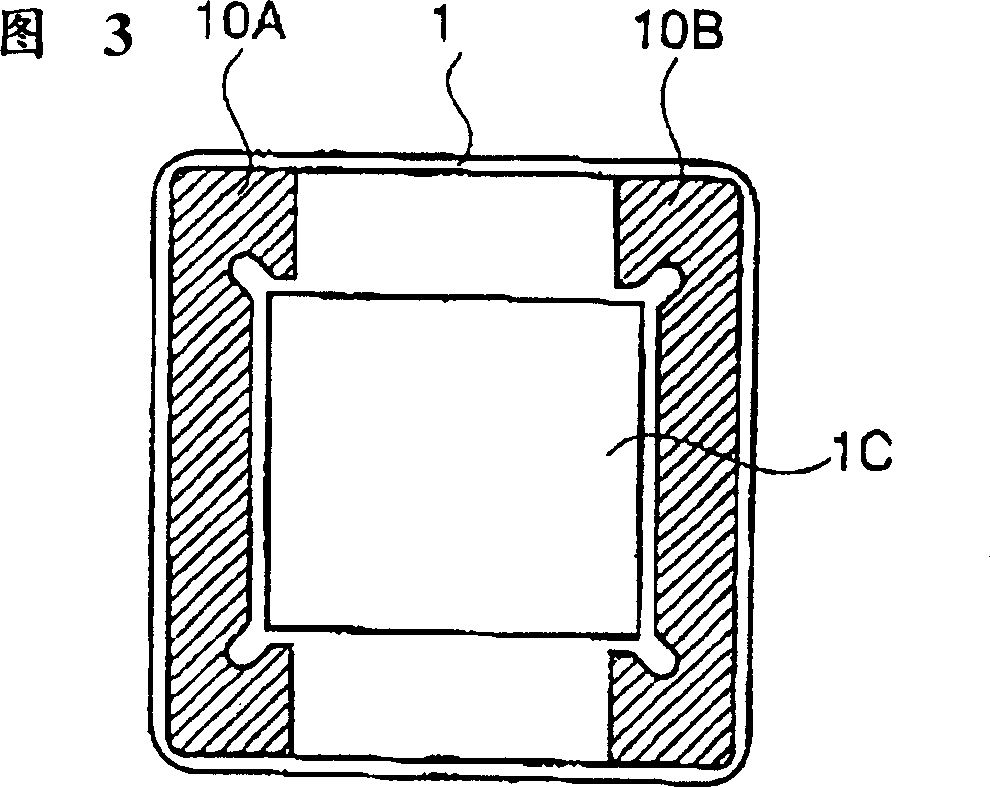

[0134] Below, refer to Figure 7 A third embodiment of the present invention will be described.

[0135] In the second embodiment, the structural member 1 is formed by integral molding in which a metal plate 10M is sandwiched in the resin structural member 1 and the back of the optical filter 3 is formed with the metal plate 10M sandwiched in the resin structural member 1 surface contact. In this example, as Figure 7 As shown, the ceramic plate 10S is sealed into the resin structure 1 except for the side facing the through portion 1C. However, the ceramic plate 10S can also be completely sealed into the structure 1 .

[0136] Other parts are formed in the same manner as the second embodiment. Like parts use the same reference numerals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com