Water treatment technology of electrolysis and packed type filter purification

A filtration purification and packing technology, which is applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of small scope, high operating cost, and huge equipment, and achieve Good manganese removal effect, good water quality and strong ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

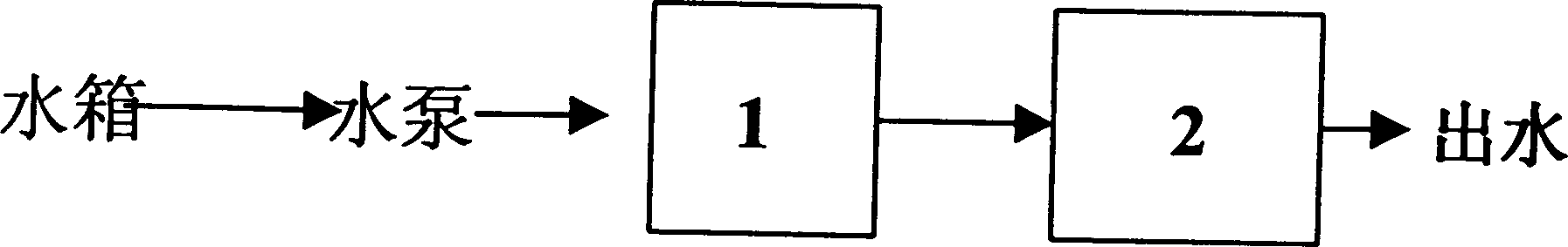

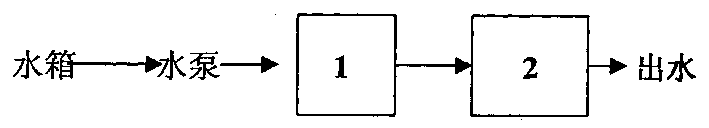

[0012] Please refer to the accompanying drawings, the water to be treated enters the electrolysis equipment 1 after passing through the water pump, and the electrolysis equipment 1 adopts direct current electrolysis technology, and the H 2 , O 2 , CO 2 and CL 2 and other gases, and enter the packing filter 2 together with water. In the packing filter 2, the bubbles generated by electrolysis contact and oxidize the packing in the packing filter. The packing can be matched with a variety of packings, such as activated carbon, quartz Wait.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com