Process for preparing ethyl lactate by reation and distillation using ammonium lactate as raw material

A technology of reactive distillation and ethyl lactate, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low reaction conversion rate, complex operation, poor water removal effect, etc. Achieve the effect of simple operation process, improved conversion rate and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

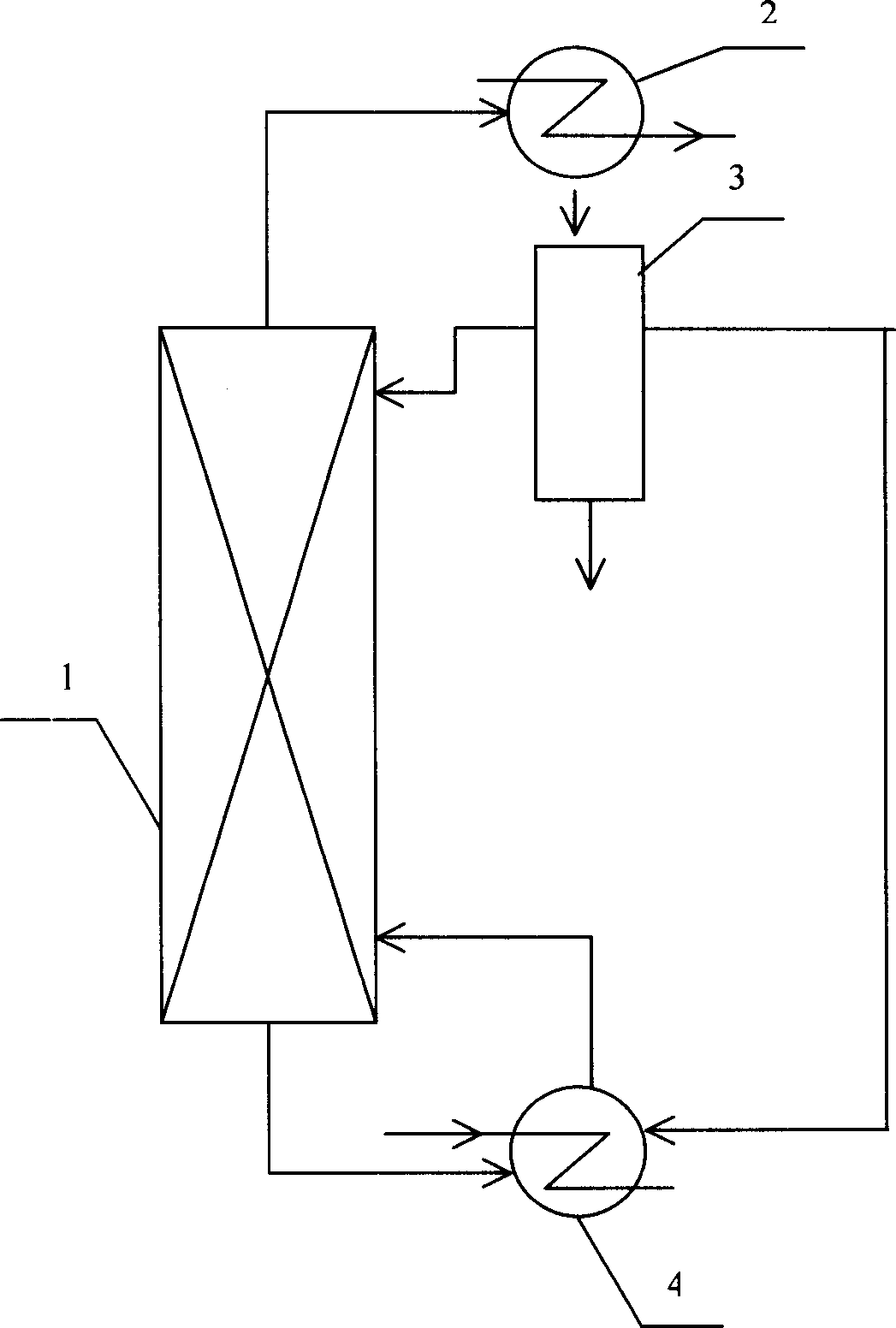

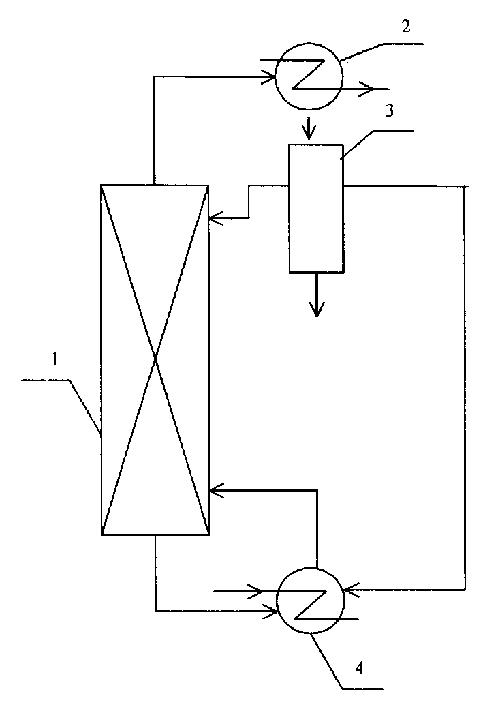

[0008] The specification of the reactive distillation device adopted in the present invention is: tower body: height 1000mm, inner diameter 35mm, built-in wire mesh θ ring, filling height 900mm, tower kettle is 1000ml. The feeding amount is: ammonium lactate 86g, ethanol 270g, benzene 40g, catalyst AlCl 3 2.14g. The operating conditions are as follows: the temperature of the reactor is controlled between 75-85°C, the temperature of the tower top is between 60-67°C, the reflux ratio is 1, and the pressure of the whole system is normal pressure. The yield of ethyl lactate was 35.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com