Process of coal-gas one-step production of direct-reduction iron and production apparatus

A process method and technology of production equipment, applied in the field of production equipment for direct reduced iron, can solve problems such as increasing production process constraints, increasing production costs, and decreasing pellet strength, so as to achieve uniform reduction reaction, increase production efficiency, and increase temperature. The effect of balanced distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

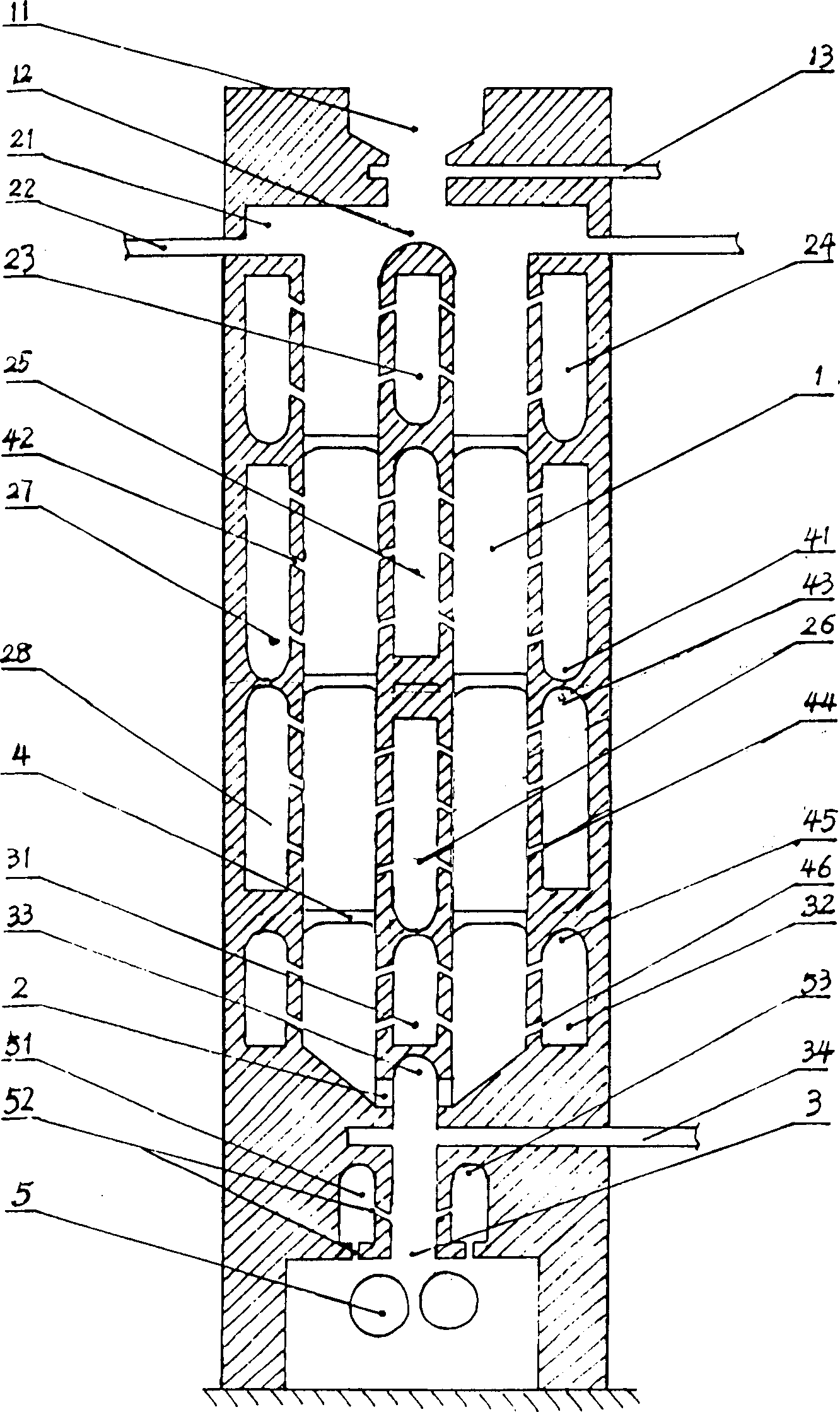

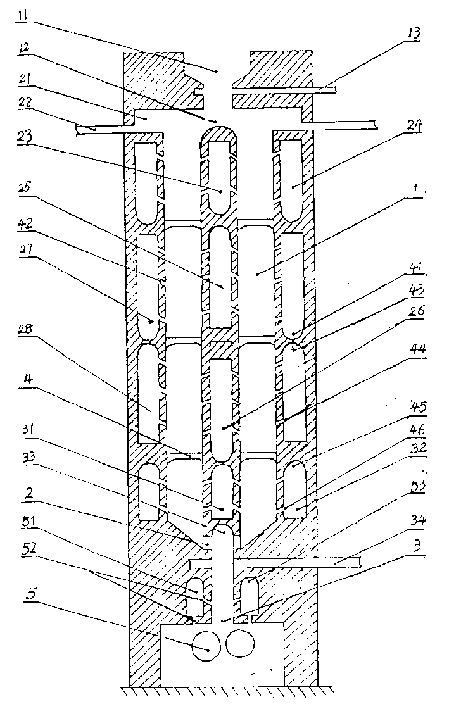

[0040] The reduction shaft furnace structure of the present invention is as figure 1 As shown, it includes: a hopper 11 located at the top of the furnace, a feed distributor 12 and an upper gas seal 13; the reducing gas chambers 23, 24 of the upper reduction section, the gas collection chamber 21 and the upper reduction tail gas outlet 22; the reduction of the lower reduction section Gas chambers 26, 27, gas collection chambers 25, 28; exhaust gas collection chambers 31, 32, 33 and heating gas passage 34 at the bottom of the furnace; The furnace walls are provided with oblique passages communicating with the reduction chamber as the corresponding reduction gas injection holes 42, reduction tail gas inlet holes 44 and waste gas inlet holes 46, and simultaneously in the reduction gas chamber, gas collection chamber and waste gas collection chamber. The chamber is also provided with a reducing gas inlet 41 , a reducing tail gas outlet 43 and an exhaust gas outlet 45 .

[0041] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com