Method for producing miro display

A technology of micro-display and manufacturing method, which is applied in the fields of instruments, nonlinear optics, optics, etc., and can solve the problems of high product cost, increased probability of waste, and difficulty of adding micro-displays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

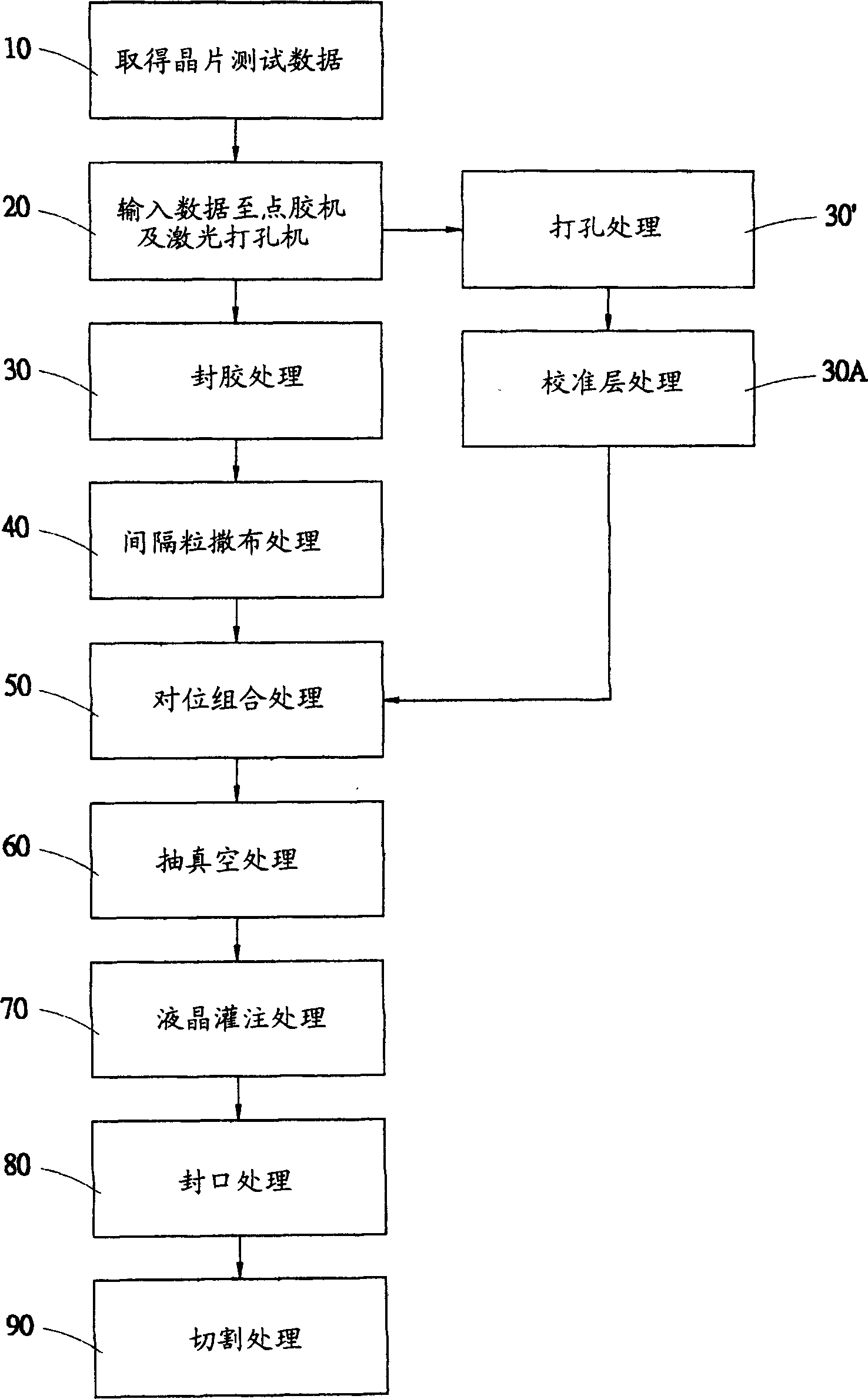

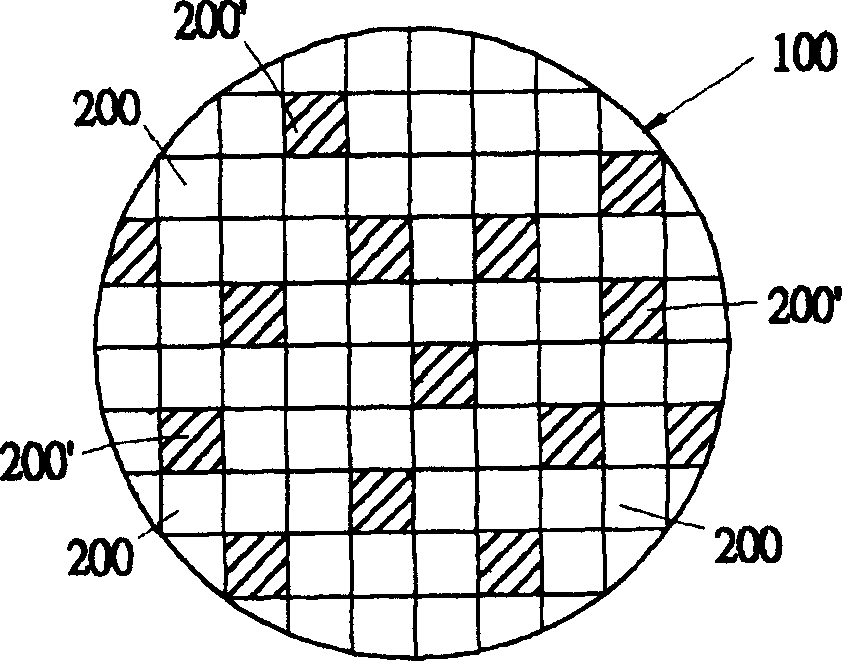

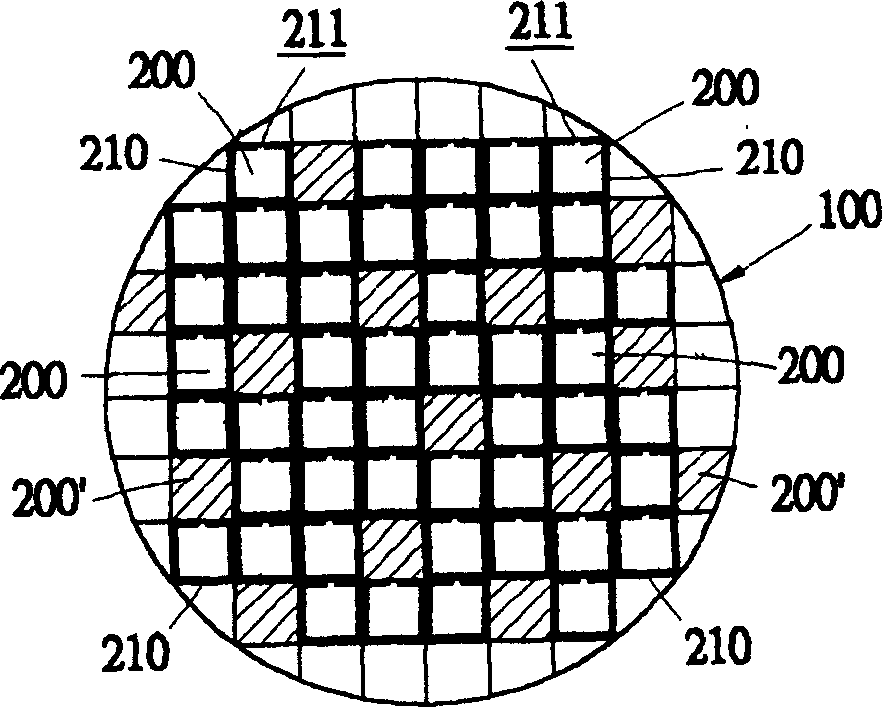

[0018] First, see figure 1 as shown, figure 1 and figure 2 Shown is the manufacturing process of the microdisplay of the present invention, wherein, shown in step 10 is to obtain the wafer test data, i.e. the wafer 100 as the basic circuit (such as figure 2 Shown) the test result data of each chip 200 and 200', this data source can be measured by the chip manufacturing plant, test plant or self-made chip test equipment, and the test methods are all in the needle test (PROB STATION) (not shown), and whether the needle measurement position is tested by moving the test head or moving the chip, the X-axis and Y-axis coordinate data and test results of the chip 200 and 200' will be Will be recorded one by one in detail with magnetic tape, magnetic disk or any other data type, and the wafer 100 disclosed in the present invention is the specification of 6 inches, 8 inches or 12 inches, and in the present invention then is with chip 200 is the test result "passed", and the chip 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com