New method for measuring alloy boiling point-method of loss of weight

A new method, the technology of the weight loss method, is applied in the direction of measuring devices, material weighing, instruments, etc., and can solve problems such as the inability to determine the boiling point of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

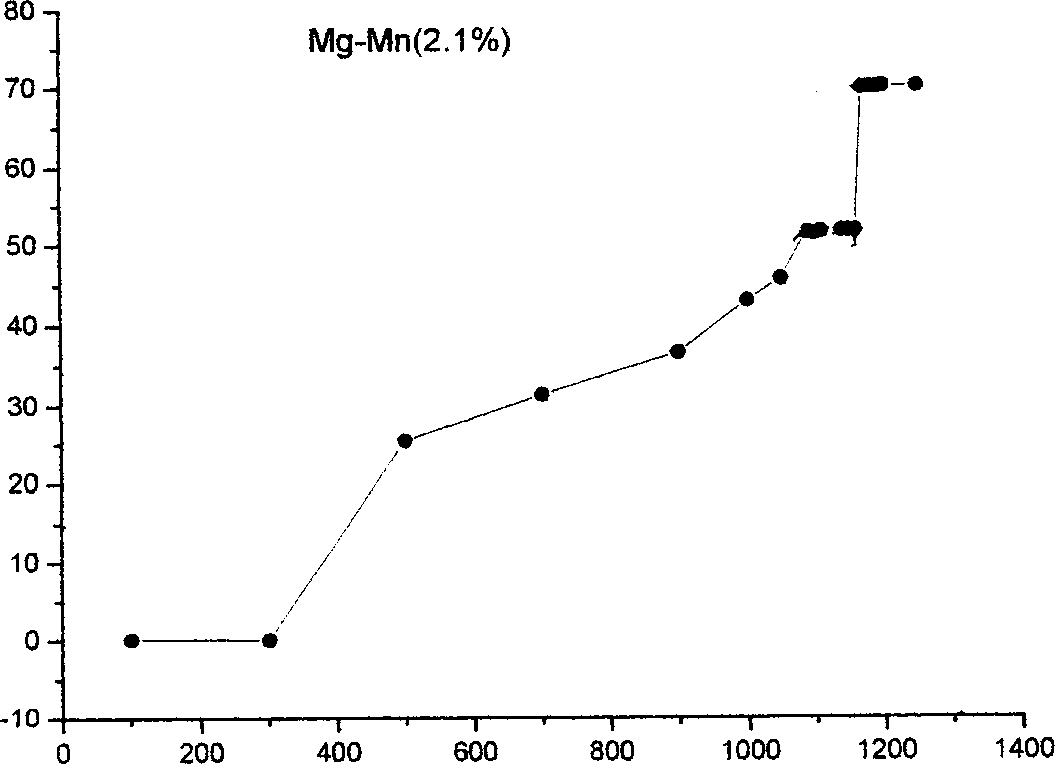

Examples

Embodiment Construction

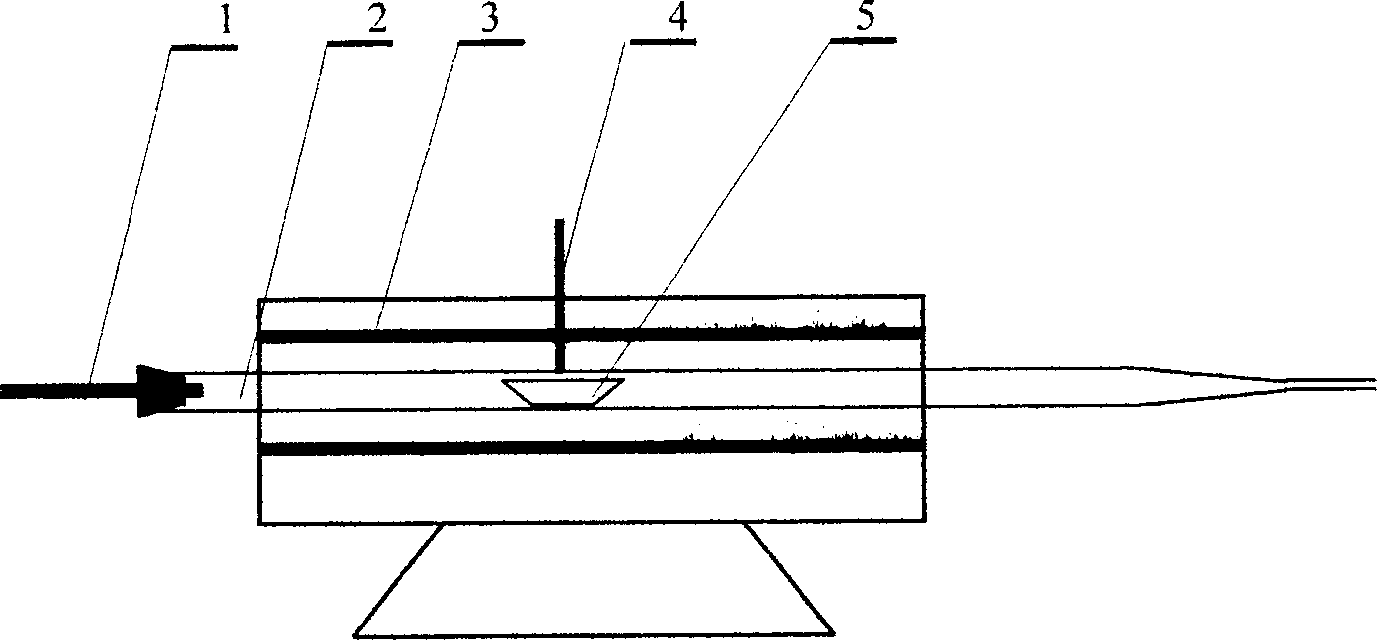

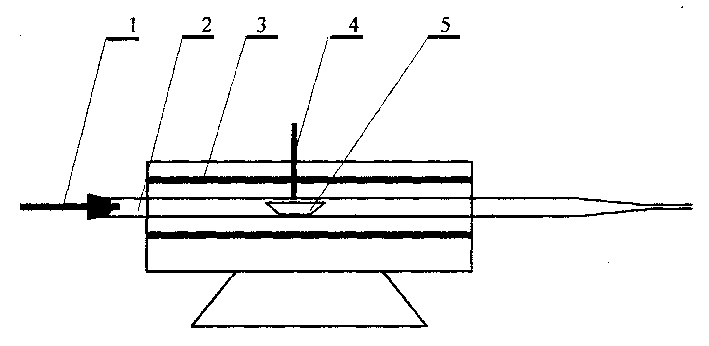

[0013] The best embodiment for realizing the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Step 1. Drill powder chips from the melted Mg-Mn alloy ingot.

[0015] Step 2. Take 0.2 grams of Mg-Mn alloy powder chips on the FA1004 electronic balance, put it into the dried porcelain boat (5), and weigh the total weight (M1) of alloy powder and porcelain boat (5) .

[0016] Step 3. Place the porcelain boat (5) containing the alloy powder in the porcelain tube (2) in the high temperature furnace (3), and pass high-purity Argon gas, when the air in the porcelain tube (2) is exhausted, keep the argon gas flow rate at 1-2L / min, the high temperature furnace (3) heats up rapidly, after reaching the predetermined temperature, keep it warm for 10 minutes, then stop heating, in the argon Under gas protection, the porcelain boat (5) is rapidly lowered to room temperature along with the high-temperature furnace (3).

[0017] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com