Method for welding bearing band

A welding method and elastic belt technology are applied in welding equipment, high-frequency current welding equipment, ammunition, etc., which can solve the problems of low welding strength, short heating time, and high welding strength, and achieve short welding time, short heating time, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

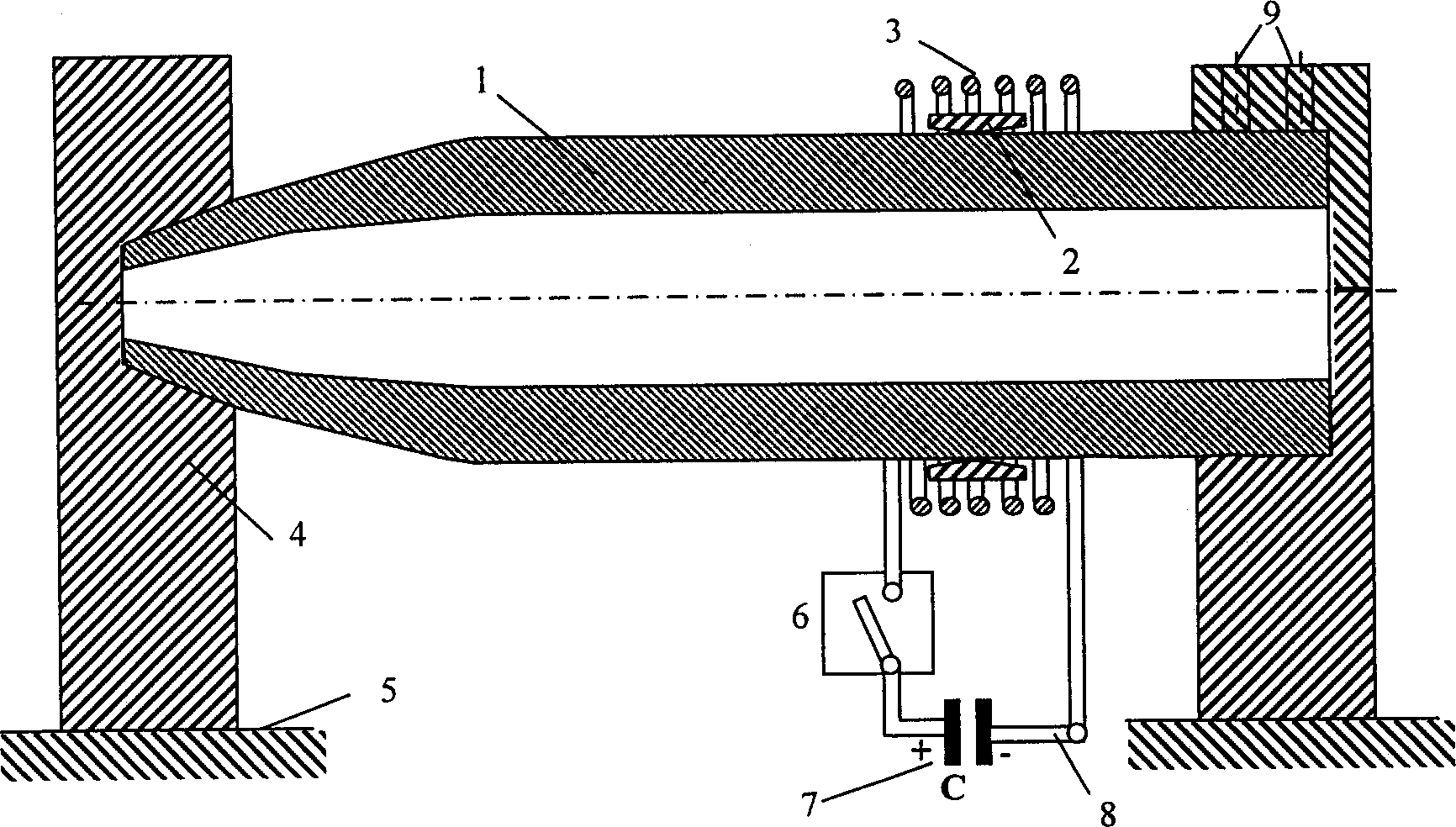

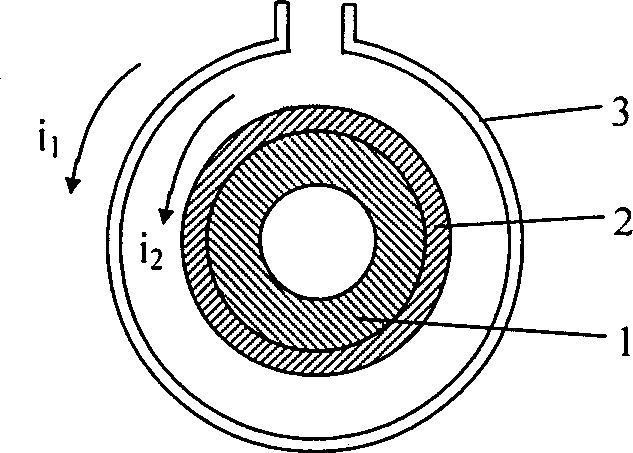

[0019] refer to figure 1 Put the elastic belt 2 on the elastic body 1, place the magnetic coil 3 outside the elastic belt 2, place the elastic body 1 in the welding fixture 4 and press it tightly, and fix it with the clamping screw 9. Close the mechanical discharge switch 6, the electric energy stored in the capacitor bank 7 discharges to the magnetic coil 3 outside the elastic belt 2, and the instantaneous strong current i through the magnetic coil 3 1 with the eddy current i induced on the belt 2 2 The interaction causes the elastic belt 2 to generate a strong electromagnetic impact force in the circumferential direction to produce plastic deformation, and destroys and removes the oxide film on the welding surface to form a firm solid-phase joint and complete the welding with the elastic body 1.

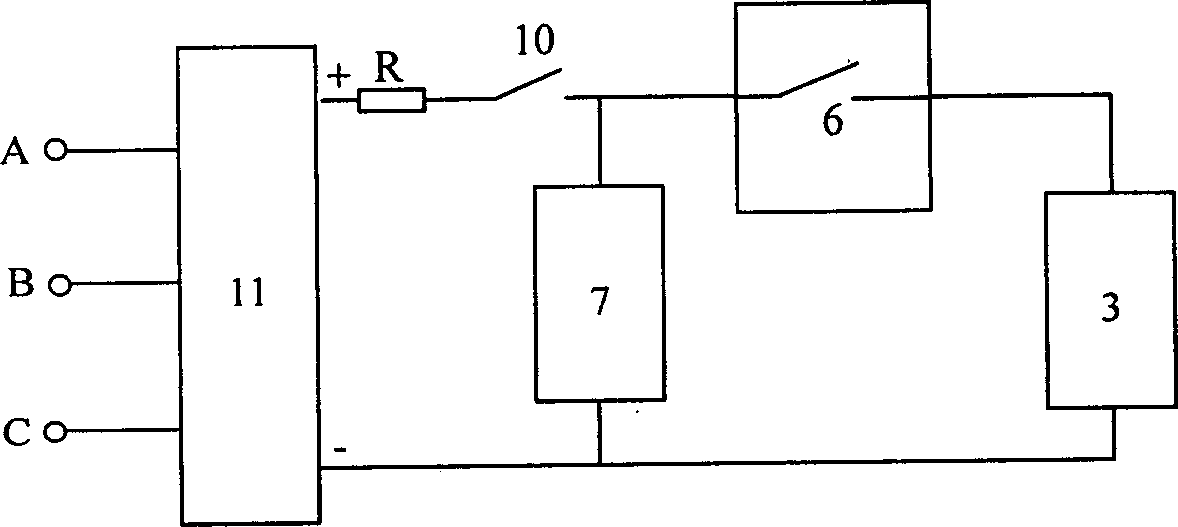

[0020] refer to figure 2 , the charging and discharging operation process of the present invention is as follows:

[0021] Power on the three-phase half-controlled bridge rect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com