Tail gas recirculating devices

A technology of exhaust gas recirculation and exhaust passage, which is applied in the direction of exhaust gas recirculation, exhaust device, muffler device, etc., can solve the problems of corrosion and corrosion of EGR cooler 40, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

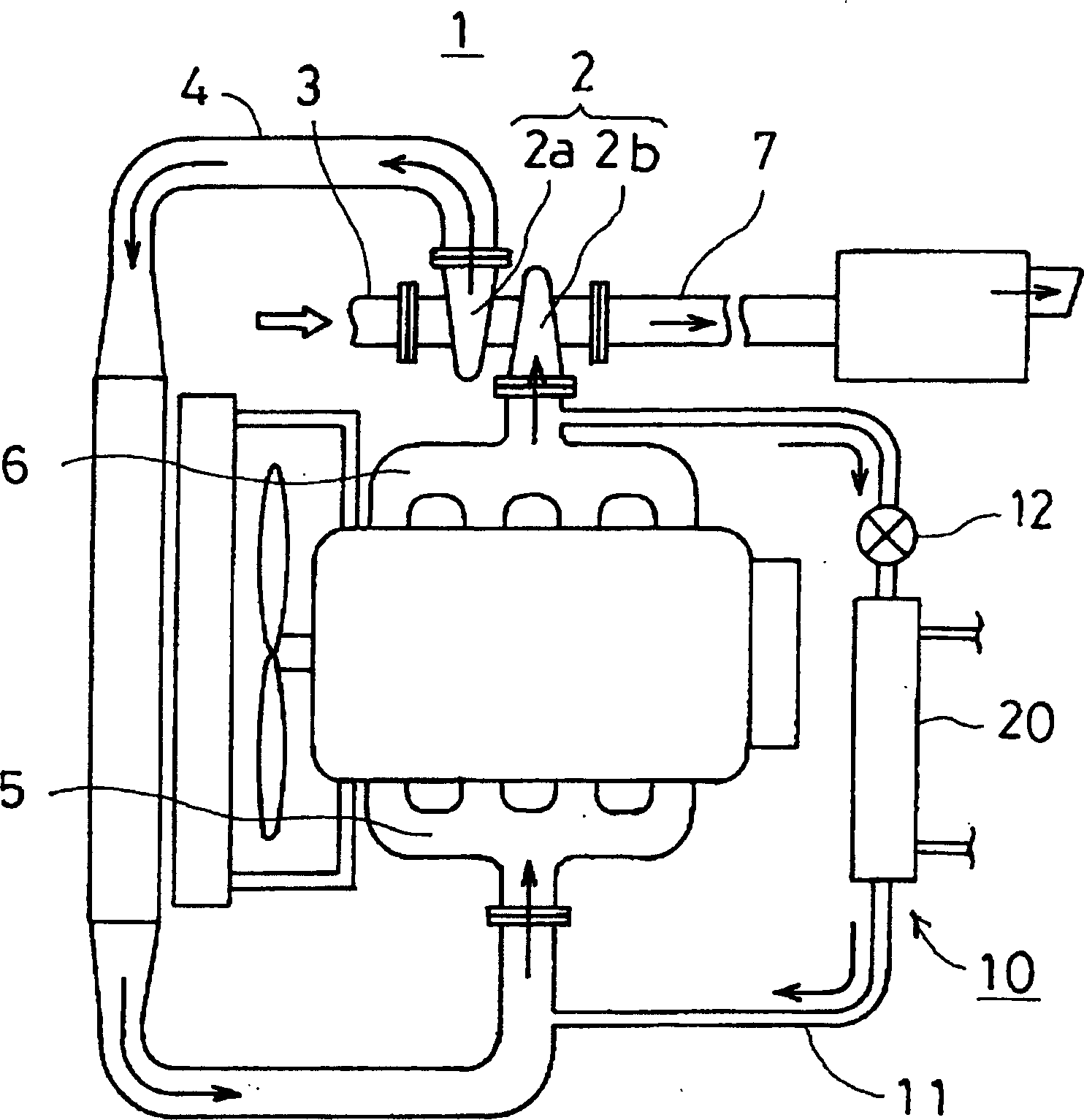

[0018] Hereinafter, embodiments of the EGR apparatus according to the present invention will be specifically described with reference to the drawings.

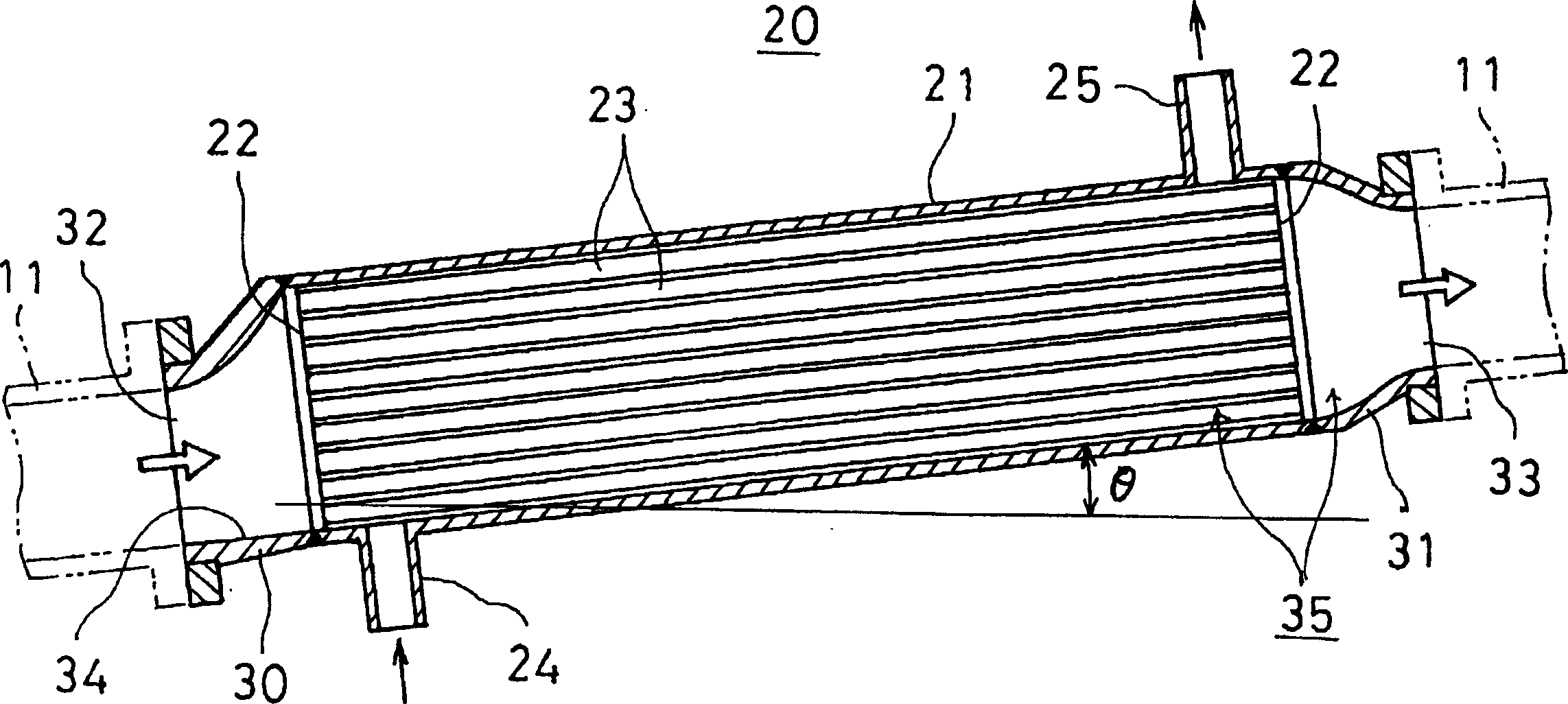

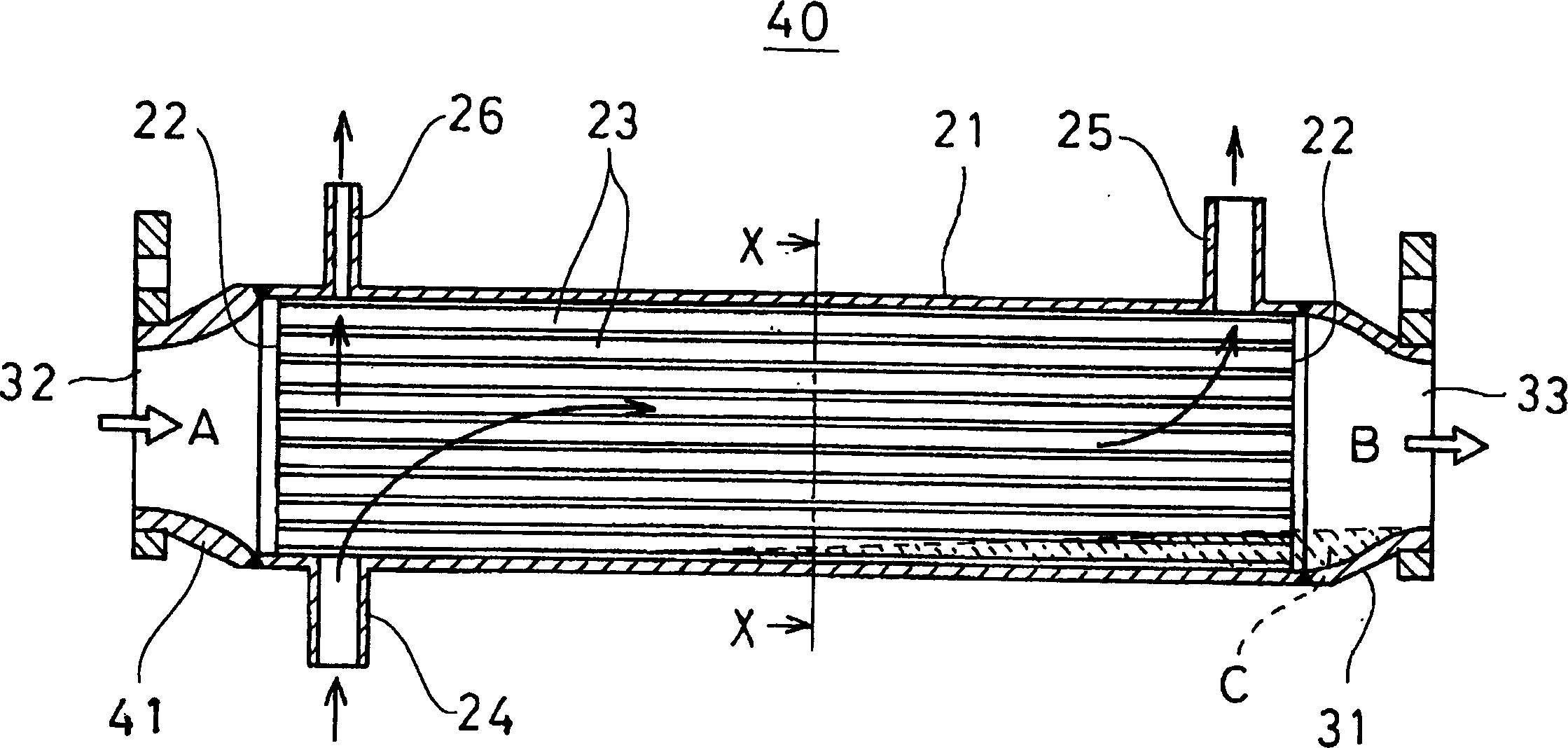

[0019] figure 1 It is a side sectional view of the EGR cooler 20 which is an embodiment of the EGR device 10 . The normal cross-sectional shape of the EGR cooler 20 is due to the Figure 4 The current one shown is the same, so detailed description is omitted here. Such as figure 1 shown, compared image 3 In the current structure described in , the same symbols are used for the same parts and descriptions are omitted, and only the different parts are described.

[0020] exist figure 1 Among them, an inlet cover 30 is fixedly connected to one side of the casing 21 , and an exhaust inlet 32 provided at the end of the inlet cover 30 is connected to the EGR pipe 11 . The bottom 34 of the exhaust inlet 32 of the inlet cover 30 is formed on the same plane as the inner bottom surface of the housing 21 or downward from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com