Power unit

A powertrain and engine technology, applied in transmission boxes, transmission devices, engine components, etc., can solve the problems of power transmission efficiency reduction, increased oil leakage, burn-in, etc., to prevent the reduction of power transmission efficiency and prevent the efficiency Effect of reducing and preventing burning phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

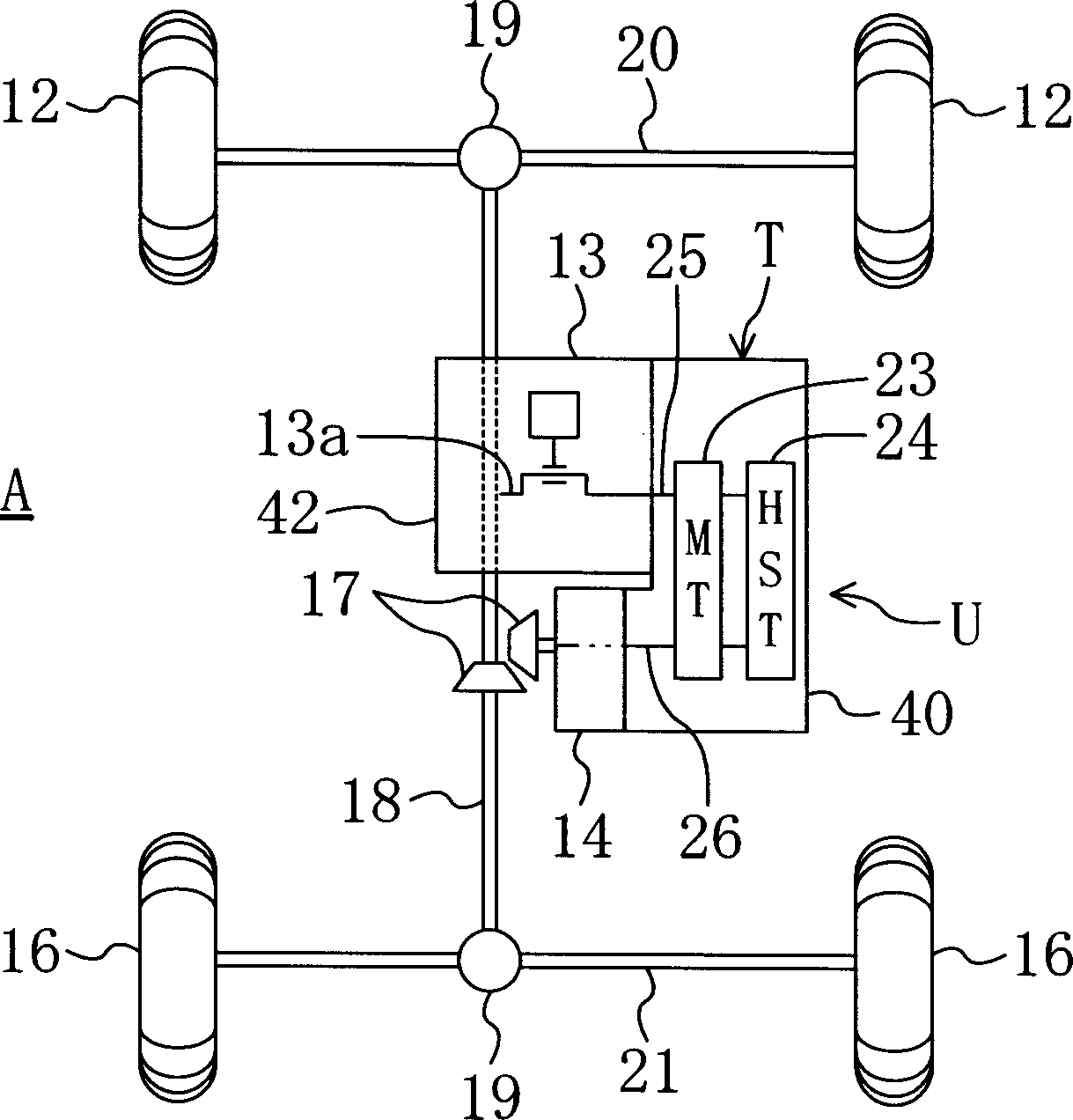

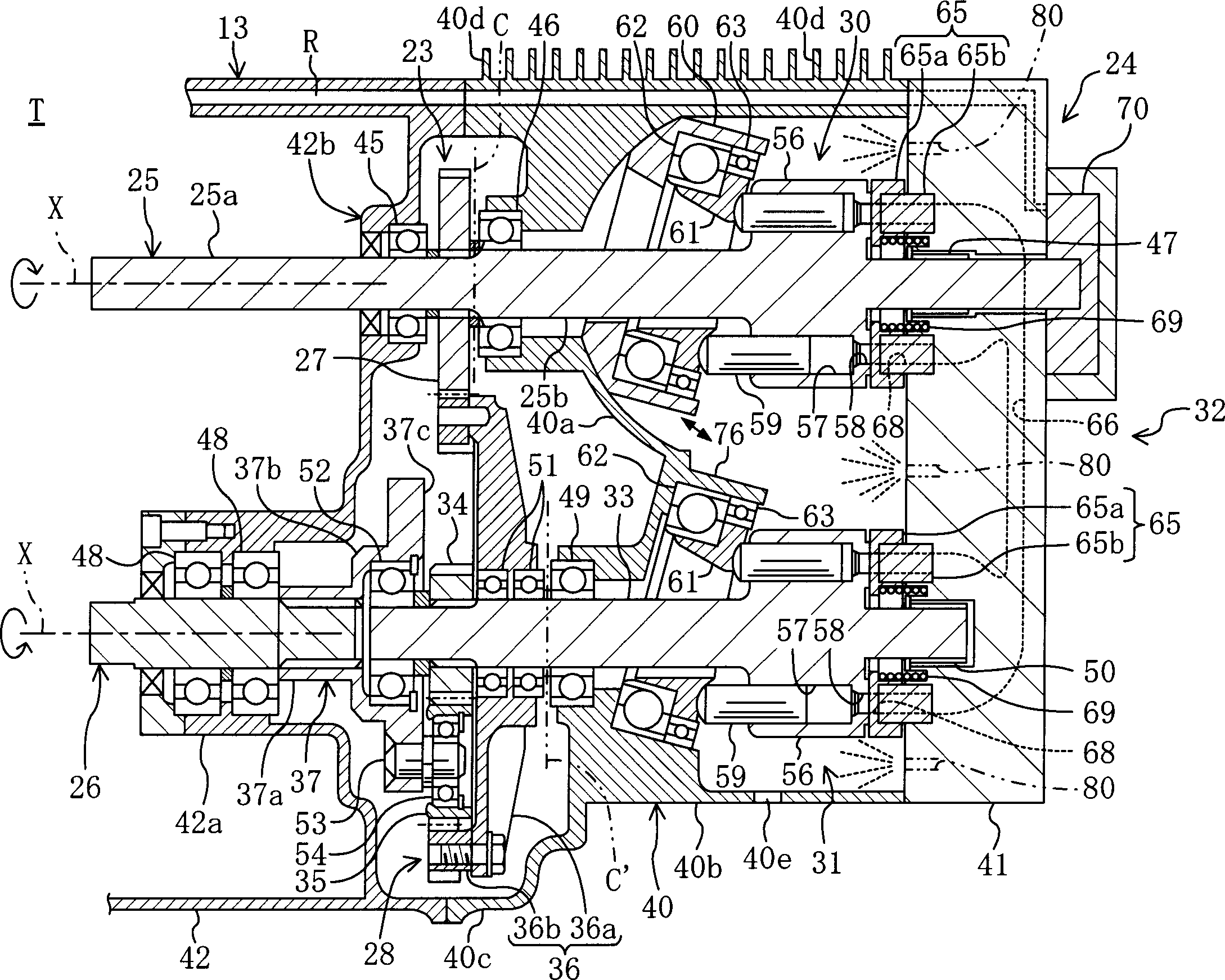

[0033] The drawings based on Embodiment 1 of the present invention will be described in detail below. In this embodiment 1, a powertrain composed of an engine and a hydraulic mechanical transmission of a speed change mechanism is mounted on a four-wheel drive all-terrain vehicle. This powertrain is composed of the engine lubricating oil and hydraulic mechanical transmission working oil.

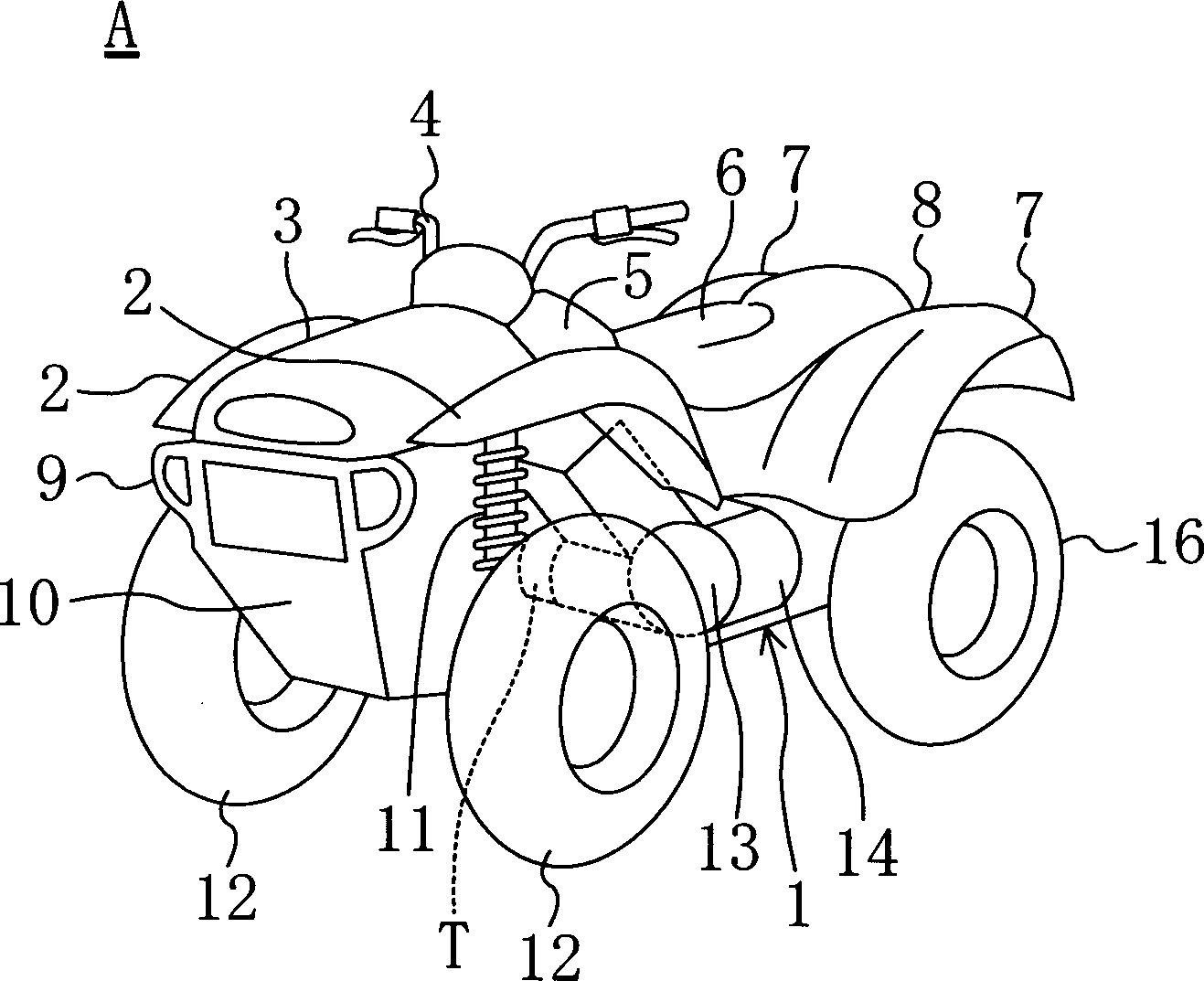

[0034] figure 1 Indicates the appearance of the all-terrain walking vehicle (A). The symbol (1) is a body made of a chassis with the specific content omitted. On the top of the body (1), there are arranged from front to rear: front, left, and right mudguards Front hood (3) of panels (2), (2), steering wheel (4), fuel tank (5), driver's seat (6), rear hood with rear left and right fenders (7), (7) (8).

[0035] Below the above-mentioned front engine cover (3), a lower engine cover (10) integrated with a bumper (9) and wheels ( 12). In addition, from the bottom of the above-mentioned oil t...

Embodiment 2

[0072] Next, Example 2 will be described.

[0073] Embodiment 2 of the present invention, such as Figure 5 As shown, an example in which an oil cooler (77) is provided as a shared oil cooling mechanism. An oil cooler (77) is provided in an oil passage (R) from the engine (13) to the hydrostatic transmission (24). The power assembly (U) of this embodiment 2, although its structure is not shown in detail, as long as there is no cooling fin on the gearbox (40), it uses basically the same parts as that of embodiment 1. . In addition, at the point of sharing engine oil from the oil tank (71) to the engine (13) and the hydrostatic transmission (24), use the oil charge pump (70) of the hydrostatic transmission (24) as in Embodiment 1. .

[0074] In such a configuration, when the common oil flows from the engine (13) to the hydrostatic transmission (24) and passes through the oil passage (R), it is cooled by the oil cooler (77) provided in the oil passage (R). And, this common e...

Embodiment 3

[0078] Next, Example 3 will be described.

[0079] For the oil delivery mechanism when the common engine oil of the hydrostatic transmission (24) is supplied from the engine (13) side in the above-mentioned embodiment 2, the oil charge pump (70) of the hydrostatic transmission (24) is utilized. , Embodiment 3 of the present invention, such as Figure 6 Shown is an example utilizing the lubricating oil pump (15) of the engine (13). In this figure, the lubricating pump (15) of the engine (13) is shown, but the lubricating oil circuit going to the engine (13) is omitted.

[0080] The cooling mechanism of shared machine oil is to use the same machine oil cooler (77) with embodiment 2. However, as in Embodiment 1, a heat radiation part is provided on the gearbox (40) etc., and the common engine oil is sent along the heat radiation part to cool it.

[0081] Even with such a configuration, when the shared engine oil flows from the engine (13) to the hydrostatic transmission (24) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com