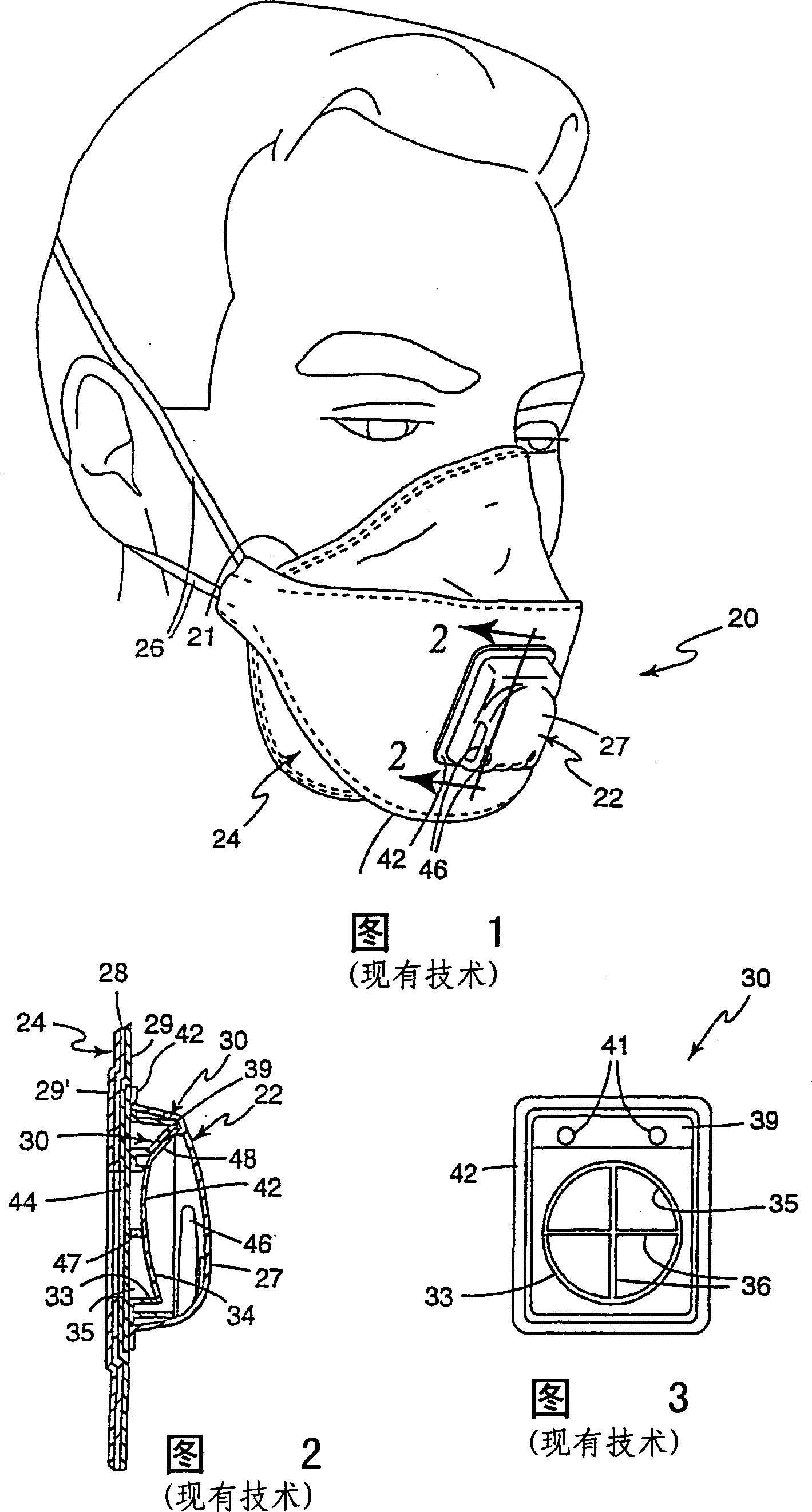

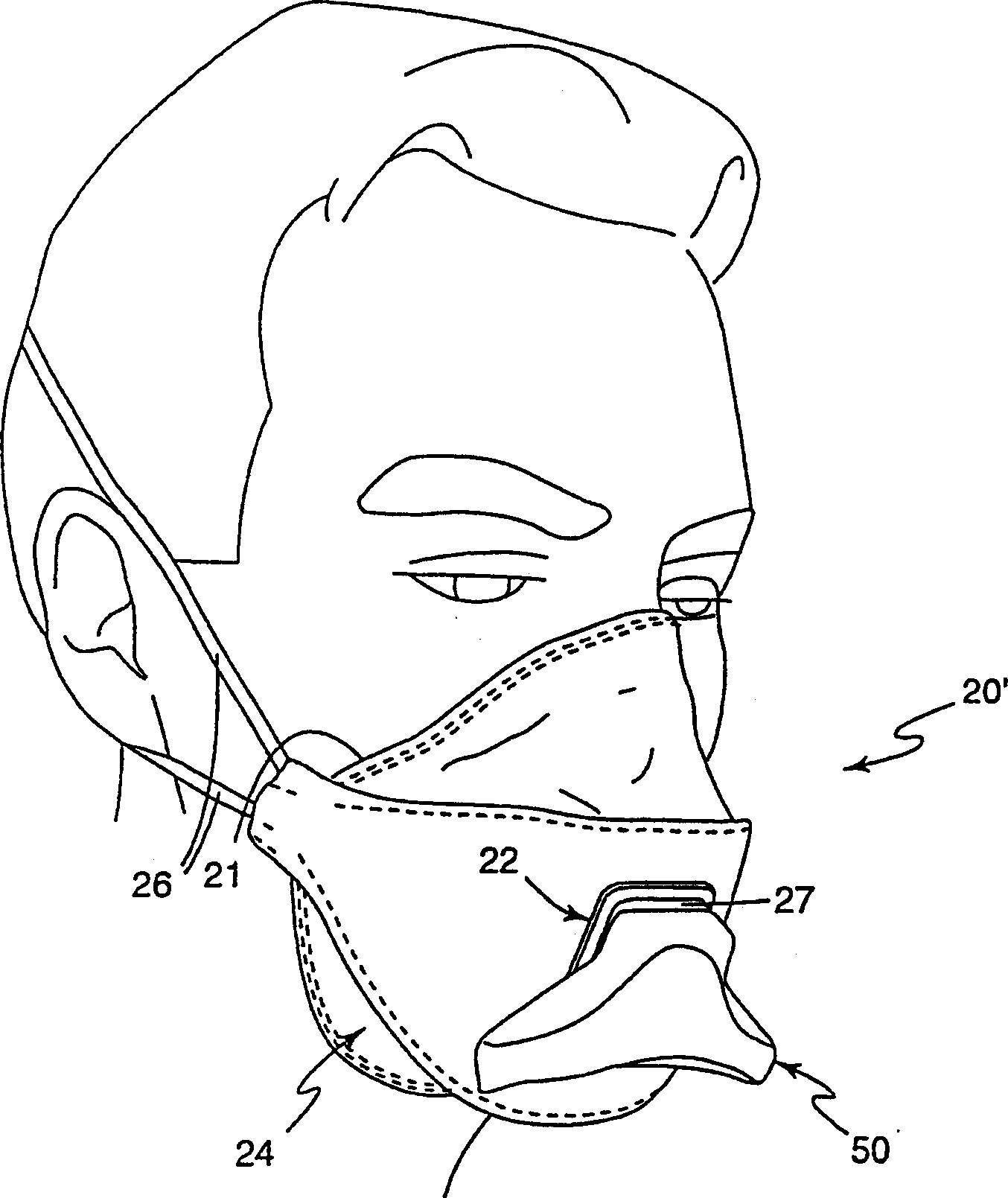

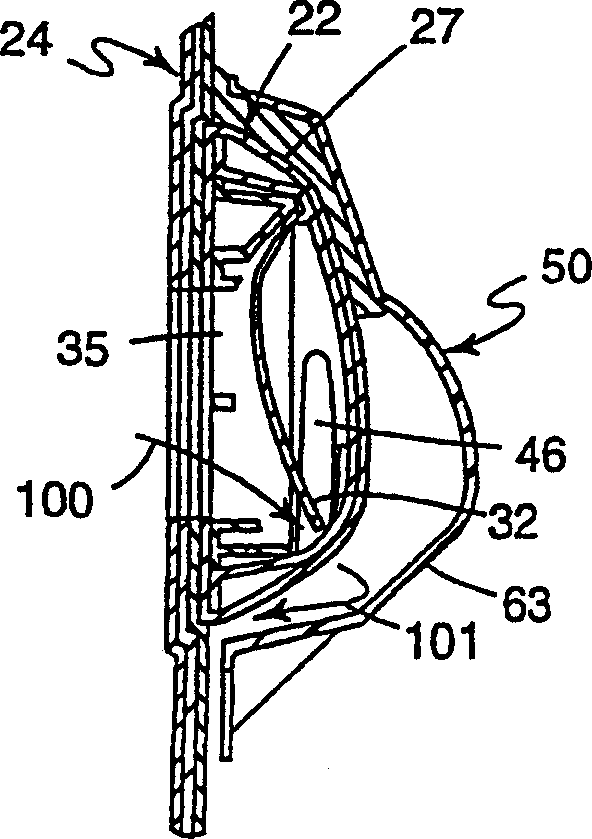

Respiration that includes integral filter element, exhalation valve and impactor element

A technology for respirators and impactors, applied in the field of respirators, which can solve problems such as entry, lack of exhalation valves, and inability to make the wearer comfortable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] A respirator with an exhalation valve and valve cover is prepared as follows. The exhalation valve used was that described in U.S. Patent 5,325,892 to Japuntich et al. and available from 3M on face masks (3MCool Flow TM exhalation valve). In order to prepare a mask with an exhalation valve for testing, the 3M grade is 1860 TM Cut a 2 cm diameter hole in the center of the N95 respirator. A sonic welder from Branson Ultrasonics Corporation (Danbury, Connecticut) was used to mount the valve to the respirator to sit over the aforementioned holes.

[0087] Four impactor elements (Examples 1-4) were vacuum formed from 0.05 cm thick clear polystyrene film. Dimensions of each impactor (see Figure 11 ) as shown in Table 1 below. Valve opening height D in table 1 j Such as Figure 10 The measurements shown are made and represent the distance of the valve opening at a given airflow and given air velocity (creating a mask pressure drop). Measured using a normal breath test....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com