Process for reclaiming polycarbonate substrate from abandoned optical discs

A technology of discarded optical discs and polycarbonate, which is applied in the field of recycling polycarbonate substrates, can solve the problems of harmful and unrecyclable substrate resins, and achieve the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

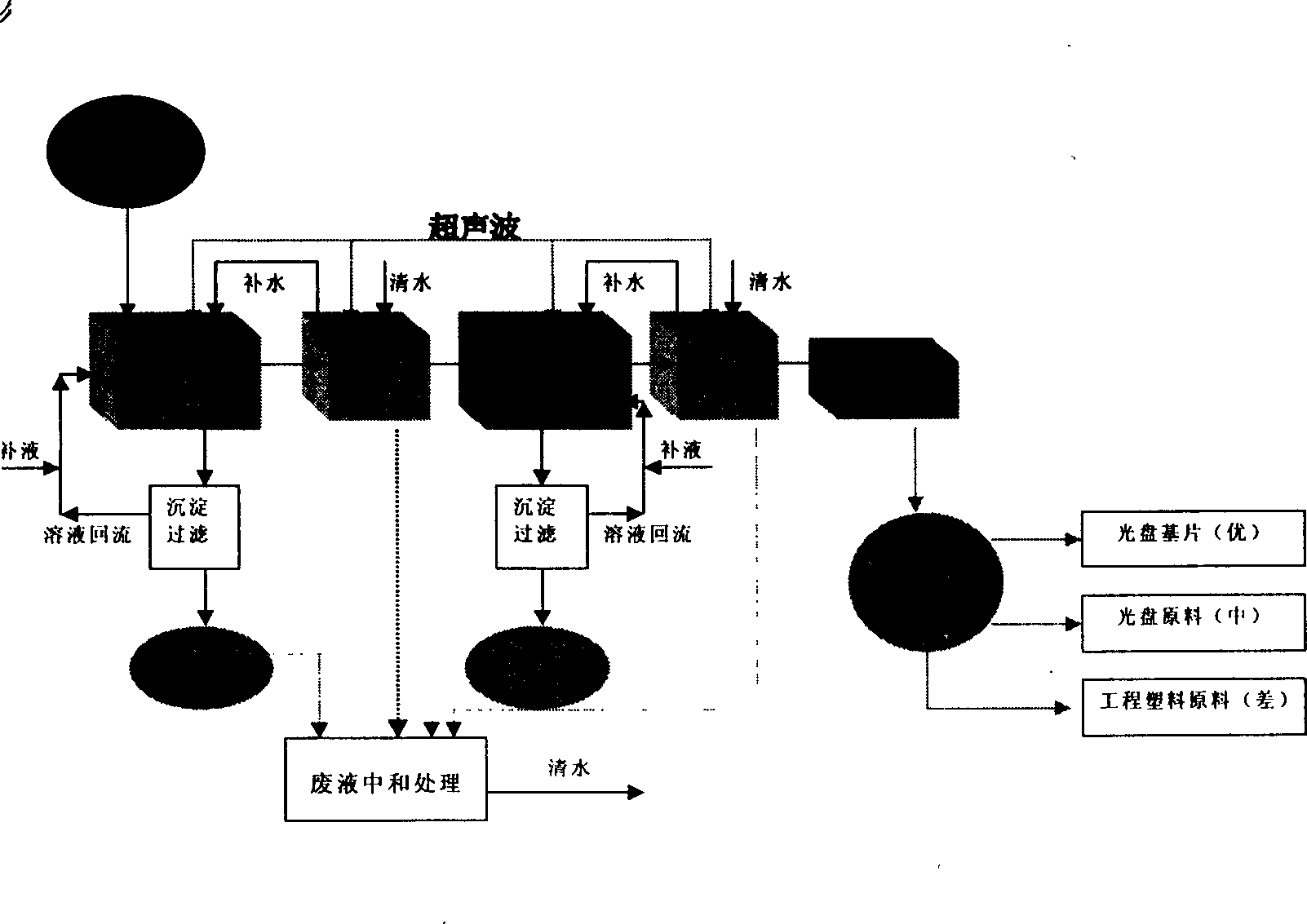

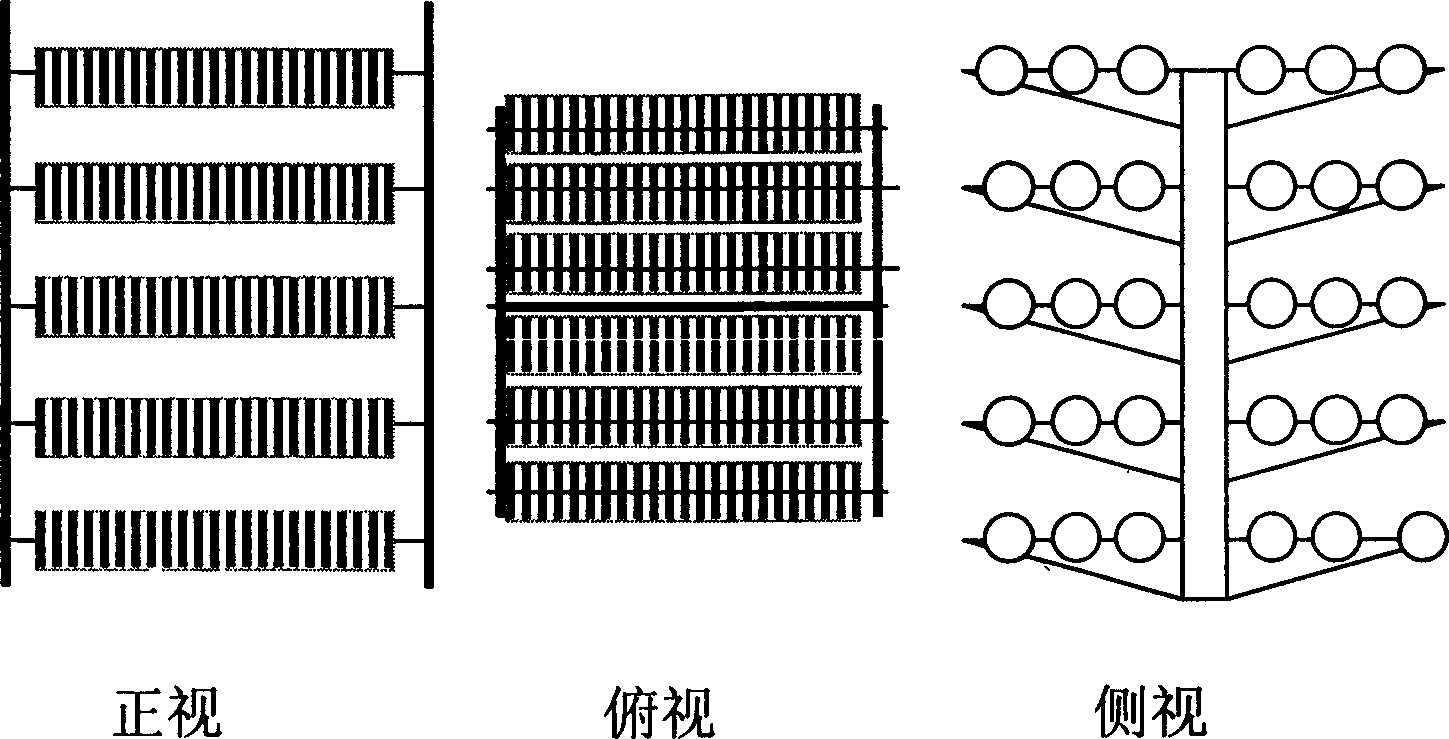

[0042] Prepare 3000ml of 15wt% NaOH solution and 15wt% HNO in a beaker 3 Solution 3000ml, placed in 500mm×300mm ultrasonic water tank, ultrasonic frequency 28KHz, power 0.4W / cm 2 , control the temperature at 50°C. Put the discarded discs into the alkaline cleaning solution, soak them for a period of time, take them out and wash them, and then put them into the acid cleaning solution, put 20 discs at a time, according to the process figure 2 Perform the operations in the order shown.

[0043] Results: 9 batches of experiments have obtained apparently qualified disc substrates, the pass rate is greater than 95%; no obvious change in the solution reactivity was observed. Before treatment, the average weight of each piece: 15.028g, after treatment, the average weight of each piece: 14.899g.

[0044] There was no significant difference in the electron probe scanning results before and after the treatment and the pristine substrate.

Embodiment 2

[0046] The method is as in Example 1. For an aluminum film optical disc, use 10wt% NaOH solution or 10wt% KOH solution or solution HNO3 alone, under the action of ultrasonic waves and a controlled temperature of 50°C, all can be obtained within 40 minutes Qualified disc substrate. But with the acid of embodiment 1, the combined use effect of alkaline solution is the best.

Embodiment 3

[0048] The method is as in Example 1, without ultrasonic action, when the temperature is kept at about 50°C; using lye or acid alone to treat aluminum-film discs, or using acid alone to treat copper-film discs, clean substrates can be obtained, but it takes a long time Long, about 2 hours or so.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com