Method for manufacturing ceramic multilayer circuit board

A technology of circuit boards and ceramics, applied in printed circuit manufacturing, circuit substrate materials, multi-layer circuit manufacturing, etc., can solve problems such as internal cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

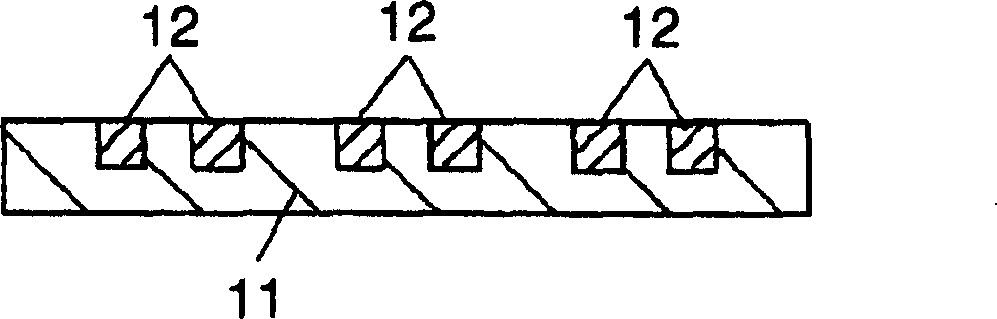

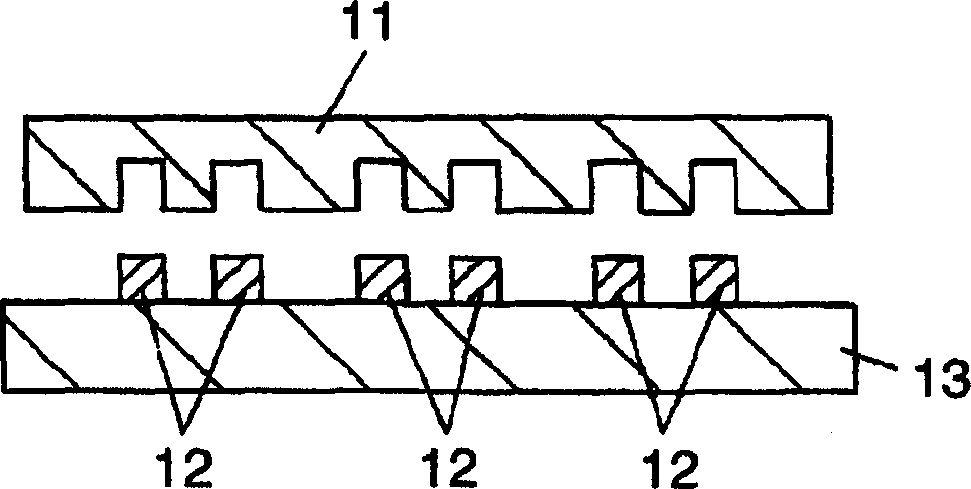

[0033] 1A to 1E illustrate a method for manufacturing a ceramic circuit board by forming conductive patterns on a ceramic body by a thick-film intaglio transfer process.

[0034] In FIG. 1A , a conductive paste 12 is filled into an intaglio plate 11 having grooves made by an excimer laser using a ceramic blade or the like and dried. As a film for gravure, after surface treatment, a heat-resistant material such as polyimide or aramid is used in advance, for example, a release agent is applied to facilitate peeling and transfer.

[0035] In addition, as the conductive paste 12 , a silver-based paste that can burn at 850° C. to 900° C. is used. The intaglio plate 11 filled with the conductive glue 12 is dried at 100° C. to 150° C. for 5 to 10 minutes. After drying, the volume of the conductive glue 12 filled in the grooves of the gravure plate 11 decreases due to the evaporation of the solvent in the glue. Therefore, filling and drying of the conductive paste 12 are repeated un...

no. 2 example

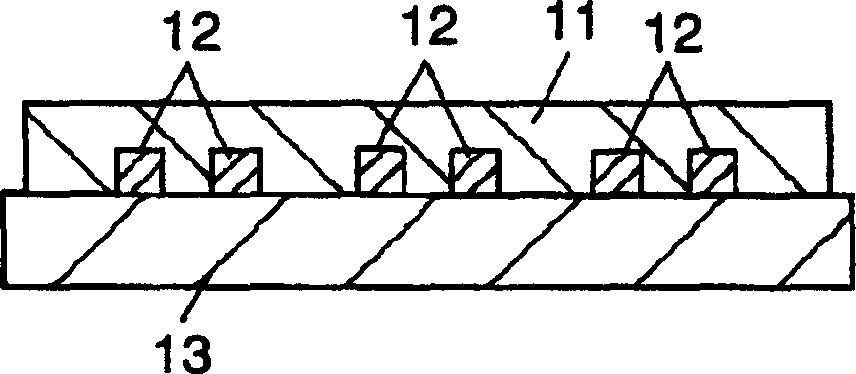

[0062] 2A to 2E show a method of manufacturing a ceramic circuit board in which a conductor pattern is formed on a ceramic body by a thick film gravure transfer process. Elements similar to those in the first embodiment have the same reference numerals.

[0063] FIG. 2A shows the process of filling the conductive paste 12 in the gravure 11 . The details are similar to Fig. 1A in the first embodiment.

[0064] Next, as shown in FIG. 2B , an adhesive solution is used to form a uniform adhesive layer 21 on the gravure 11 filled with the conductive paste 12 by dipping or using a roll coater. The adhesive solution is obtained by dissolving thermoplastic resins such as butyral resins and acrylic resins in organic solvents such as toluene, acetone, ethylacetate and formazan. Ethyl ketone, and preparation.

[0065] Next, as shown in FIG. 2C, a conductor pattern is formed on the ceramic body 13 by temporarily transferring the conductive paste. The transfer of the conductive paste i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com