Flue gas purifying method and apparatus for bag type dust remover

A bag-type dust collector and flue gas purification technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of low utilization rate of adsorbents, reduced dust removal efficiency, large equipment investment, etc., and can be easily promoted. The effect of using, simple process, reliable and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The method of the present invention has been described in the summary of the invention, and the schemes are exactly the same, so no more details are given.

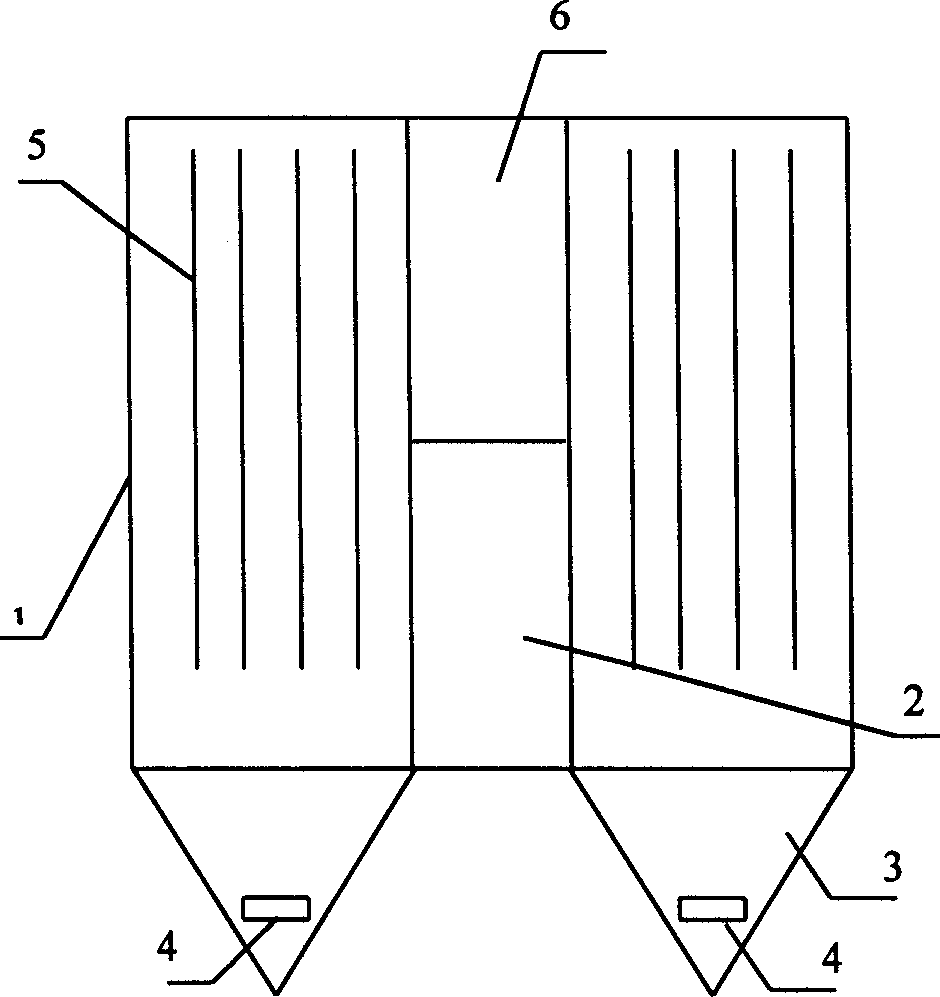

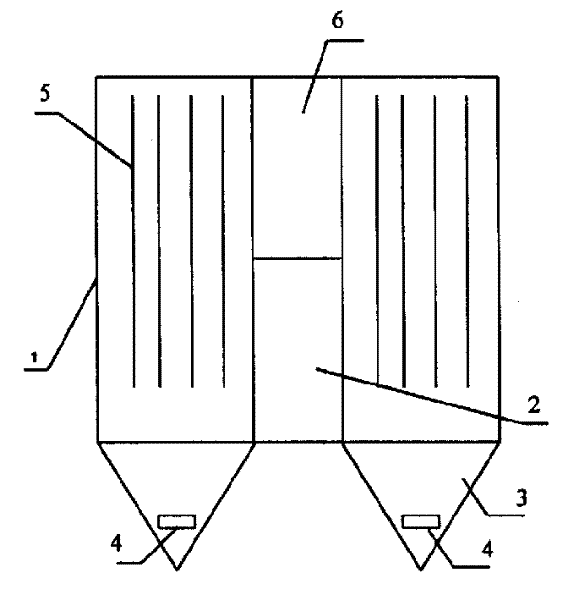

[0013] Referring to the accompanying drawings, the device of the present invention comprises a bag filter 1 composed of a flue gas inlet 2, an ash bin 3, a filter layer 5, and a smoke outlet 6, and is characterized in that, at the inlet of the bag filter 1 Air fluidizers 4 are arranged in each ash bin 3 on the lower side of the flue gas port 2, and the compressed air required by each air fluidizer 4 can be supplied by a connected compressed air pipe, or by a bag filter dust removal device. compressed air supply.

[0014] The adsorbent in the flue gas inlet 2 of the bag filter 1 is fluidized to a certain height under the action of the air fluidizer 4, and the flue gas containing viscous dust enters the flue gas inlet 2 of the dust collector 1, Flowing through the lower ash bin 3, it carries the fluidized fly ash to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com