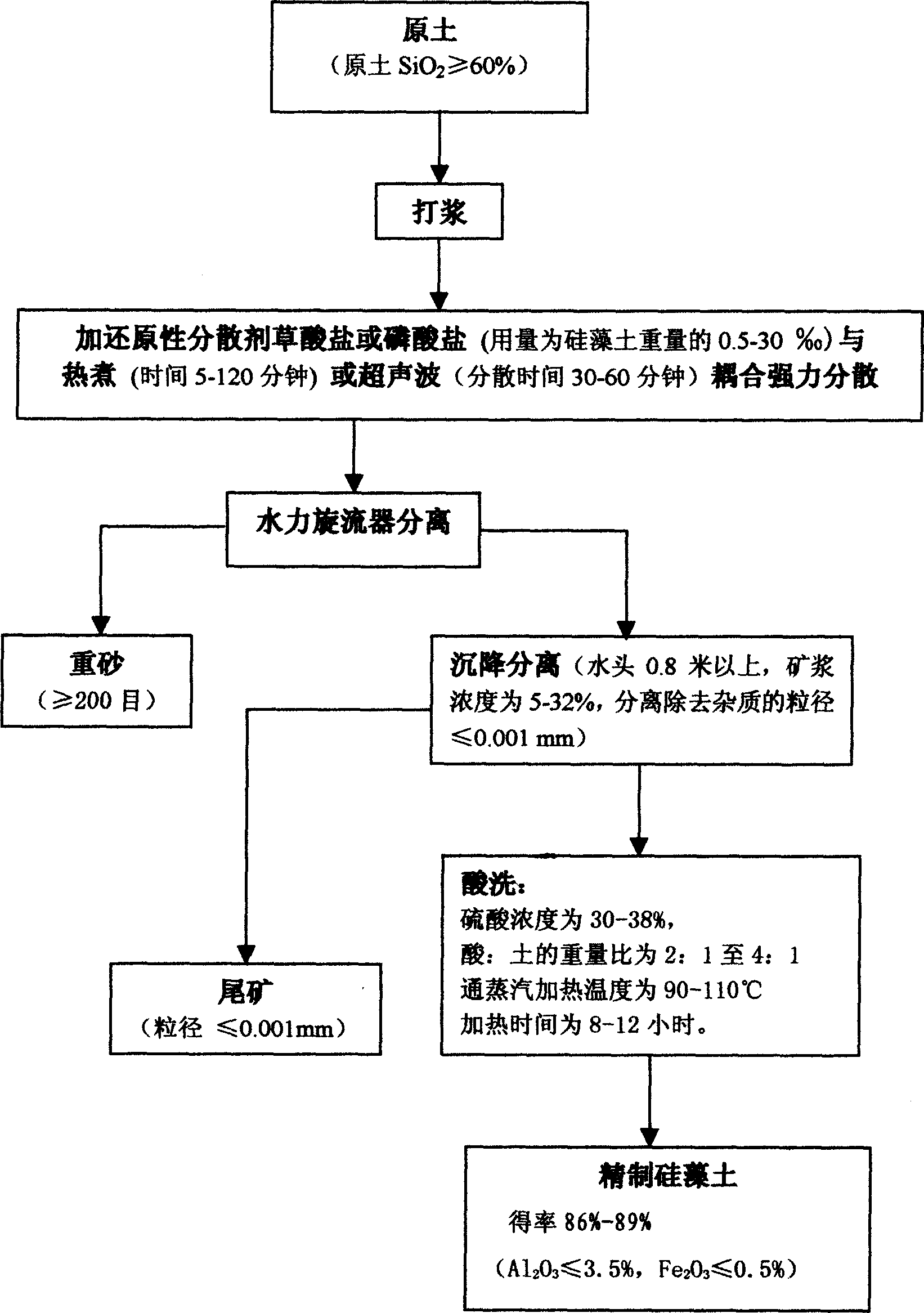

Two-stage method for separating and refining diatomaceous earth

A technology of refining diatomite and two-step method, which is applied in the field of two-step separation and refining of diatomite, which can solve the problems of environmental pollution, difficult recovery, fluorine ion entry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take a 5000 ml beaker, add 2900 ml of water to 1000 g of diatomite, and beat the diatomite into a slurry; add 100 ml of 15% sodium hexametaphosphate solution, and stir evenly. Put it in an electric furnace and heat it to a slight boil, and keep it for 45 minutes. After the slurry is cooled, separate and remove the heavy sand larger than 200 meshes. The remaining slurry is placed in a bucket with a water level of 120 cm. Settling and separating 4 times to remove tailings less than 1 micron . Then use 30% sulfuric acid to carry out pickling according to acid: soil ratio of 4:1, and the heating time is 8 hours. After the sample is dried, refined diatomite is obtained. Its chemical composition and pickling yield are as follows: Table 1 Pickling and refining Elemental composition (%) of diatomite and pickling yield sample ignition loss SiO 2 Fe 2 o 3 al 2 o 3 TiO 2 Pickling yield (%) Raw soil 6.69 66.66 3.75 18.20 0.71 Pickling refined soil 2.18 90.51 0.27 ...

Embodiment 2

[0024] Take a 5000ml beaker, add 2900ml of water to 1000g of diatomite, and beat the diatomaceous earth into a slurry; add 100ml of 15% sodium oxalate solution, stir well, and disperse with ultrasonic waves for 30 minutes; separate and remove more than 200 The purpose is heavy sand, and the remaining slurry is settled and separated twice in a bucket with a water level of 120 cm to remove tailings less than 1 micron. Then use 38% sulfuric acid to carry out pickling according to acid: soil ratio of 2:1, and the heating time is 12 hours. After the sample is dried, refined diatomite is obtained. Its chemical composition and pickling yield are as follows: Table 2 pickling and refining Elemental composition (%) of diatomite and pickling yield sample ignition loss SiO 2 Fe 2 o 3 al 2 o 3 TiO 2 Pickling yield (%) Raw soil 6.69 66.66 3.75 18.20 0.71 Pickling fine soil 2.11 90.81 0.25 3.24 0.41 86.3 Pickling acid: soil is 2:1, pickling time is 12 hours, and pickling temp...

Embodiment 3

[0026] Take a 5000 ml beaker, add 2900 ml of water to 1000 g of diatomite, and beat the diatomite into a slurry; add 100 ml of 15% sodium hexametaphosphate solution, and stir evenly. Put it in an electric furnace and heat it to a slight boil, and keep it for 45 minutes. After the pulp cools, separate and remove the heavy sand larger than 200 meshes. The remaining pulp is placed in a bucket with a water level of 120 cm. Settle and separate for 3 times, and remove the tailings smaller than 1 micron . Then use 35% sulfuric acid to carry out acid pickling at a ratio of 3:1 of acid: soil, and the heating time is 10 hours. After the sample is dried, refined diatomite is obtained. Its chemical composition and pickling yield are as follows: Table 3 pickling and refining Elemental composition (%) of diatomite and pickling yield sample ignition loss SiO 2 Fe 2 o 3 al 2 o 3 TiO 2 Pickling yield (%) Raw soil 6.69 66.66 3.75 18.20 0.71 Pickling refined soil 2.20 91.09 0.21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com