Method for continuous preparation of solid natural gas

A natural gas and solid technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems that it is difficult to meet the needs of large-scale natural gas solidification storage and transportation, does not have universal adaptability, and has limited production scale, and achieves rapid gas-solid separation Simple, speed up convective heat transfer, enhance the effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

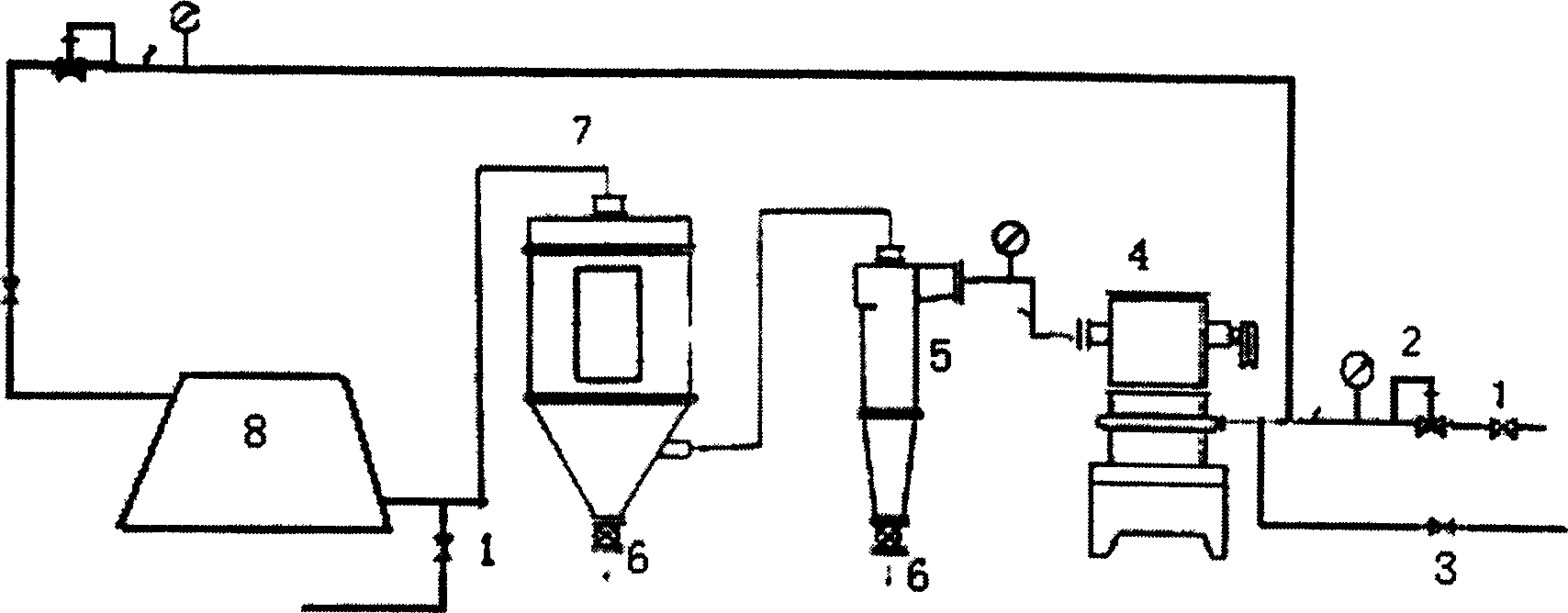

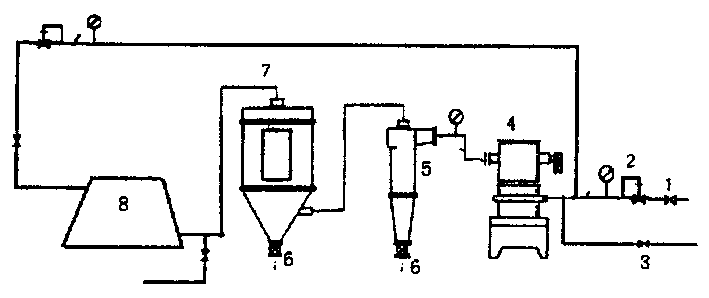

[0035] see figure 1 , figure 2 , a method for continuously preparing solid natural gas, comprising the following steps in sequence:

[0036] (1) The raw natural gas from the wellhead or the pipeline passes through the shut-off valve 1 and adjusts the pressure through the pressure regulating valve 2, and the water enters the natural gas continuously and evenly through the flow regulating valve 3 to moisten the gas;

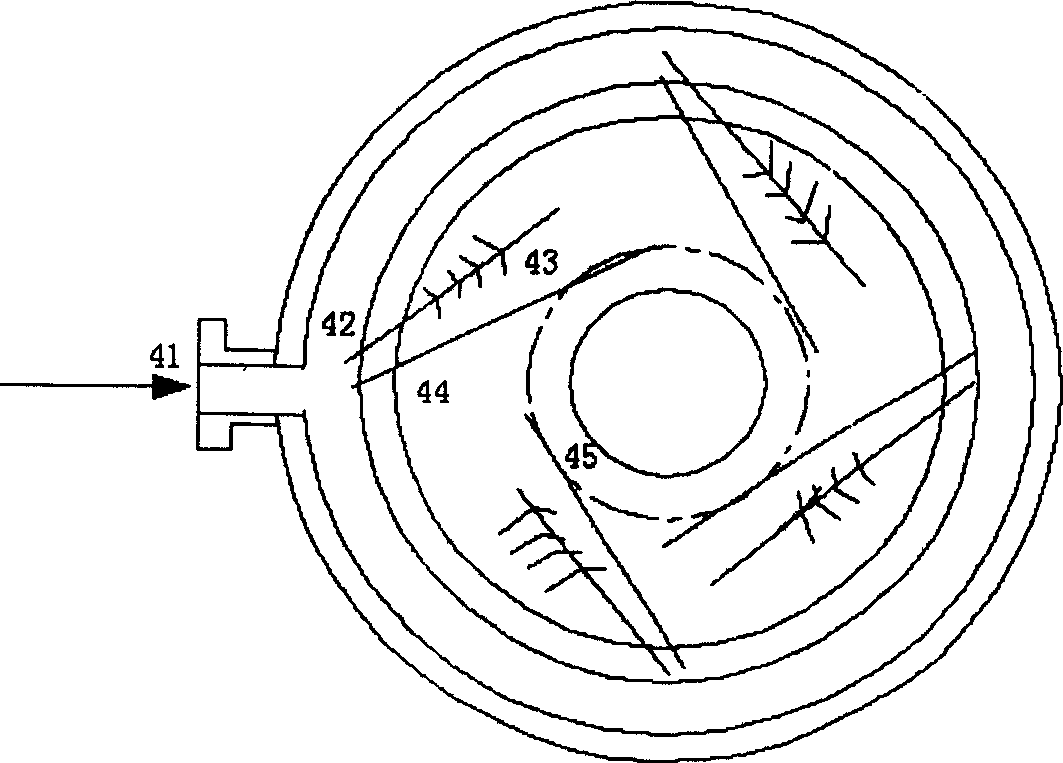

[0037] (2) The water-containing natural gas enters the reactor 4 through the gas flow inlet 41, and a plurality of nozzles 42 that form a certain angle (60-90 degrees) with its radial direction are evenly distributed around the cylindrical reactor 4, and the water-containing natural gas flows through the nozzles. Jet flow 43 is formed, and throttling expansion occurs at the same time. The reaction zone 44 in the reactor rotates at a high speed to rapidly generate solid hydrate, and then enters the centrifugal zone 45;

[0038] (3) The airflow containing solid hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com