Retardation setting tendon cladding equipment and uses thereof

A technology of prestressed tendons and cladding devices, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of not being able to meet construction requirements well, and achieve the effects of light weight, simple and unique structure, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

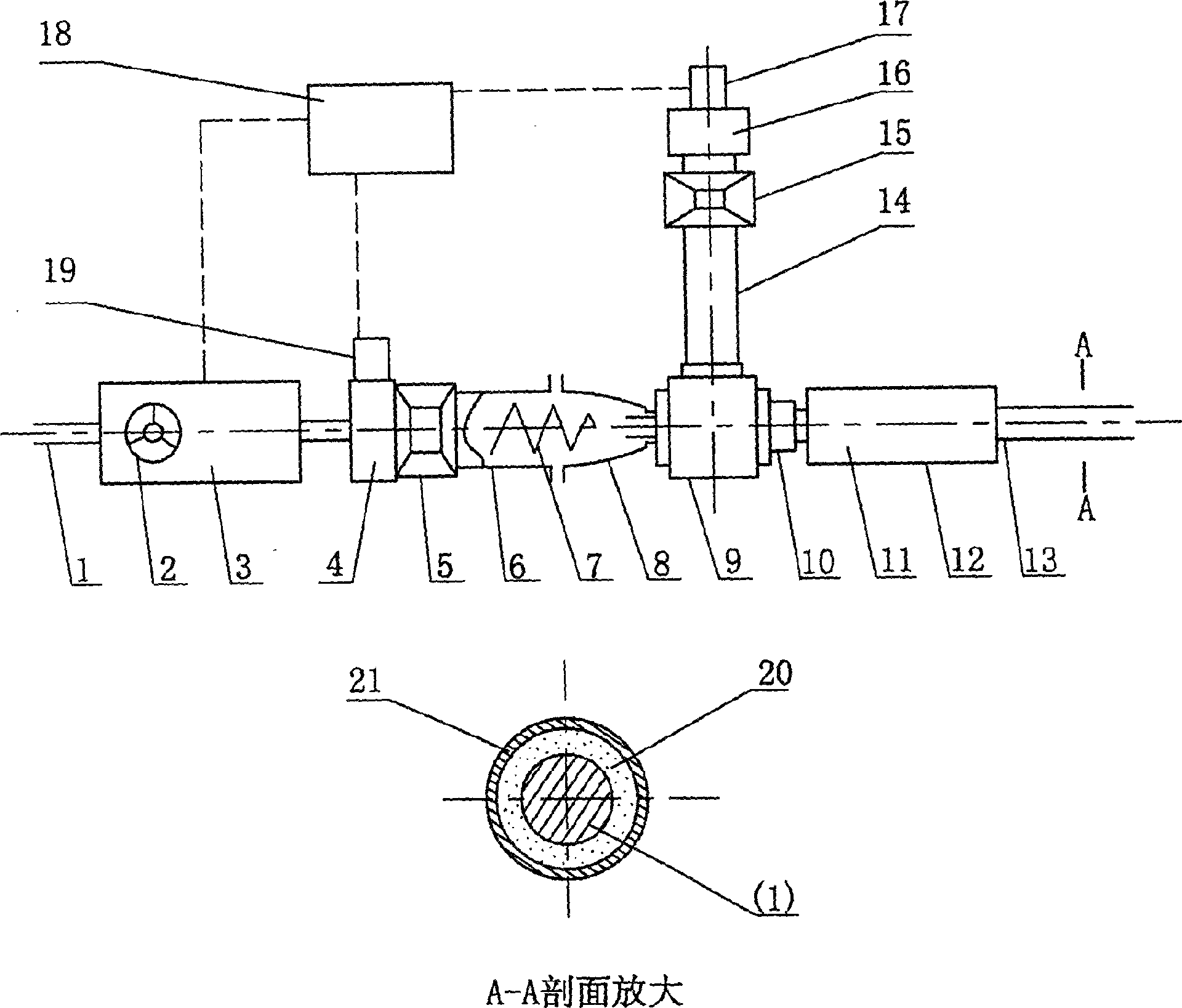

[0010] With reference to Fig. 1, present embodiment is made up of traction mechanism 3, retarding mortar propulsion mechanism 4, plastic coating mechanism 16, setting cooling system 11, dragging control system 18, and they are all arranged on a frame. The traction mechanism 3 adopts frequency conversion speed regulation and belt-covered structure. The belt-covered belt compresses and conveys the prestressed steel bar 1, and the hand wheel 2 adjusts the pressing force. This structure has a large traction force and a wide range of speed adjustment. When running at low speed, it has relatively hard mechanical properties to prevent crawling, thus realizing continuous, reliable and smooth conveying of prestressed steel bars, and controlling the cross-sectional size of coated products to make the coating process stable; retarded mortar The propulsion mechanism 4 is composed of a hydraulic motor 19, a hopper 5, a screw 7, a barrel 6, and a straight-through machine head 8. The motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com