Preparation method of ZnAl*0*/alpha-Al*0*composite base material

A composite substrate and mixed material technology, which is used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of complex process, high lattice mismatch, high dislocation density, etc., and achieves simple process and high quality. Stable and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

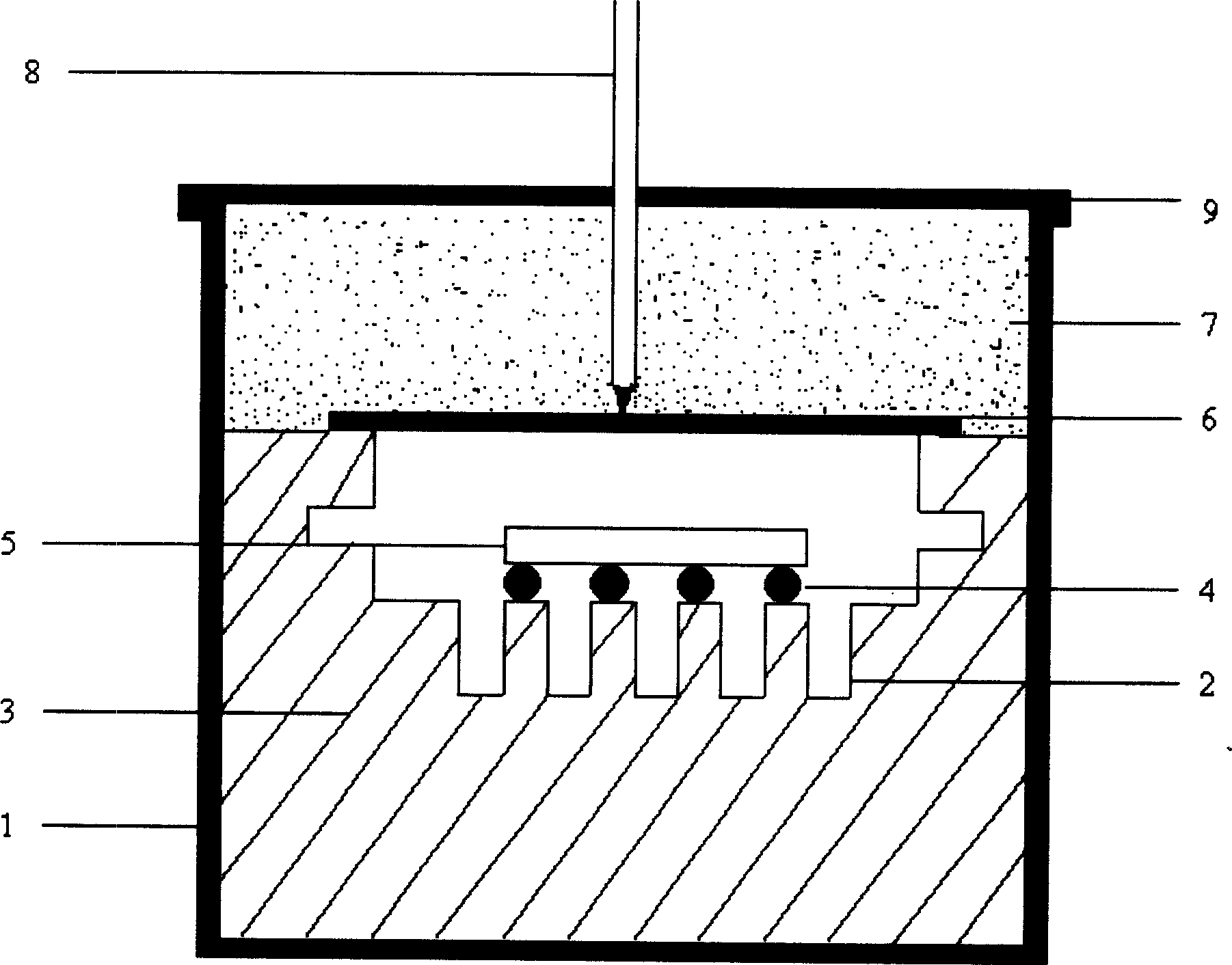

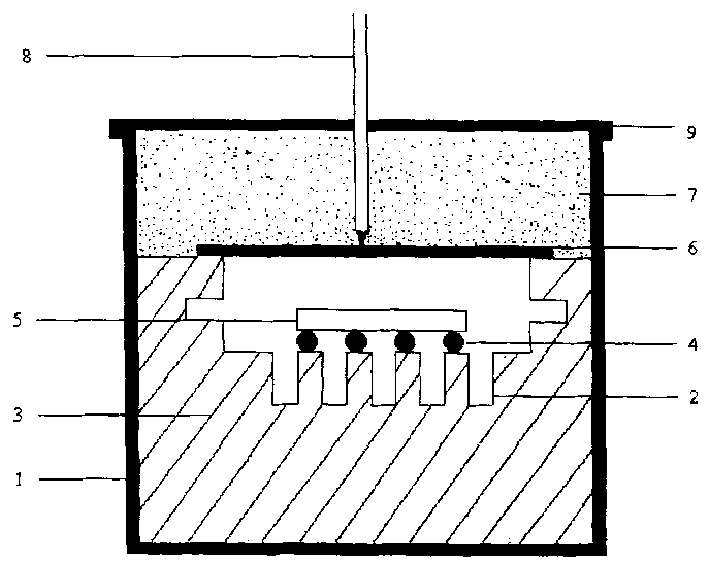

[0017] see first figure 1 , the gas phase transport equilibrium (VTE) technology used in the present invention prepares composite substrate material ZnAl 2 o 4 / α-Al 2 o 3 For a schematic diagram of the device, see figure 1 , in the platinum crucible 1, a certain ratio of ZnAl with pores 2 is placed 2 o 4 Mix block 3 with ZnO, the upper part of block 3 is platinum wire 4, sapphire α-Al polished on both sides or single side 2 o 3 The wafer 5 is placed on the platinum wire 4, and the upper part of the material block 3 has a platinum sheet 6 and ZnAl 2 o 4 Cover with powder 7 mixed with ZnO, insert thermocouple 8 into powder 7, and add platinum cover 9 to the top of crucible 1 to seal.

[0018] Vapor Transport Equilibrium (VTE) technology is a mass transfer process, so there should be sufficient supply of ZnO in the crucible, and secondly, the balance of the gas phase depends on the continuous transfer of ZnO from ZnAl to ZnO. 2 o 4 To maintain the volatilization in th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap