Friction machine device and method for mfg LCD component by utilizing same

A technology of liquid crystal display element and manufacturing method, applied in nonlinear optics, instruments, optics, etc., can solve the problems of affecting the effect of rubbing treatment, polluting the surface of the roller, etc., and achieve the effect of reducing the bad phenomenon of liquid crystal elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

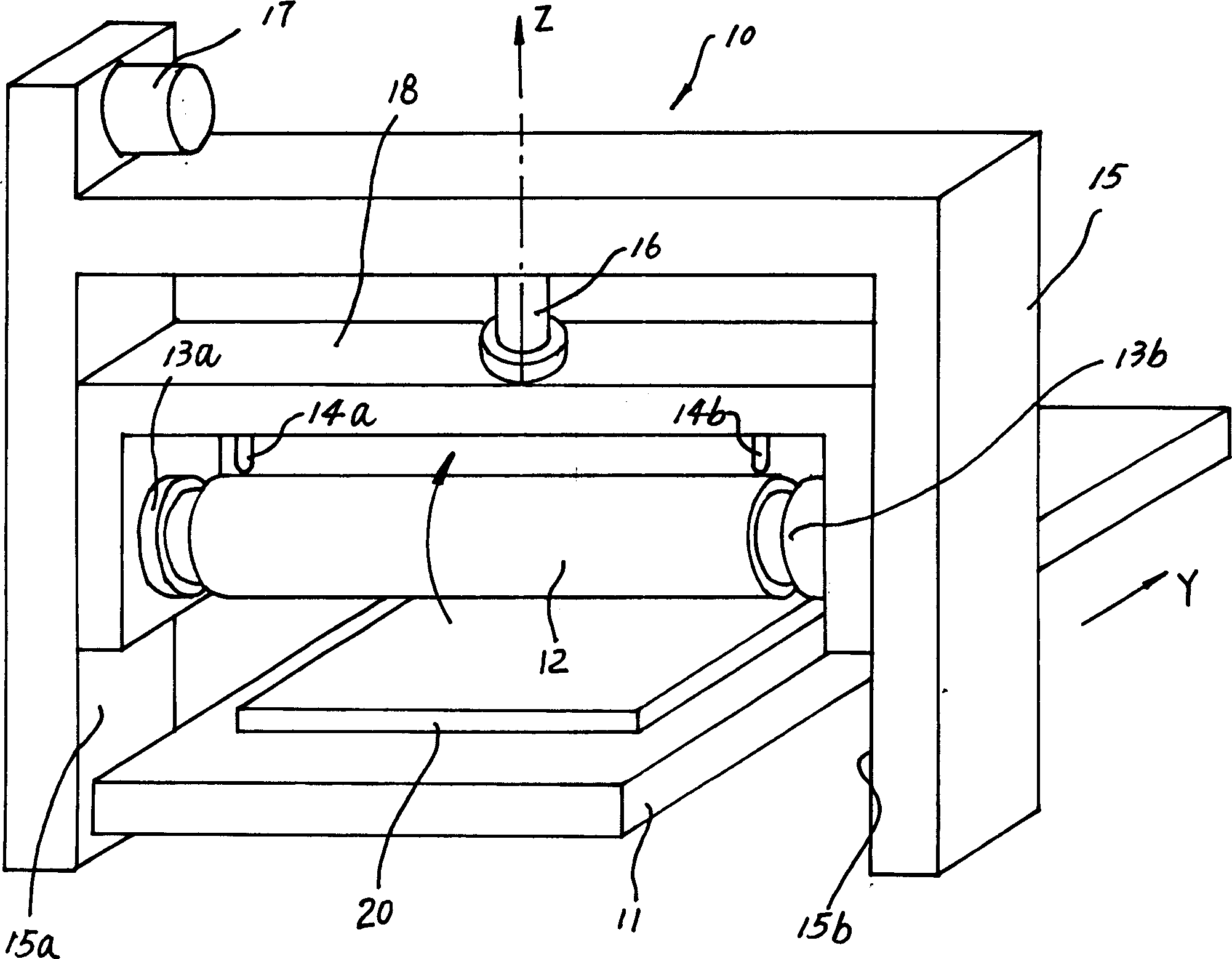

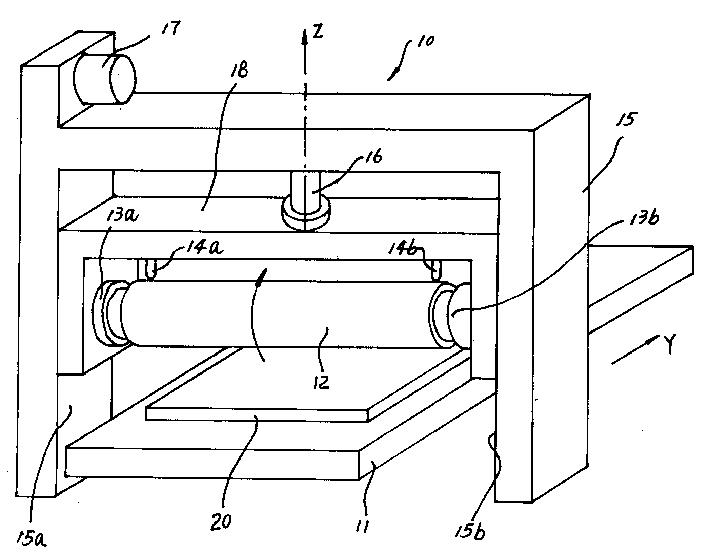

[0023] Embodiment one: see attached figure 1 As shown, a rubbing machine device 10 for rubbing the alignment film of a liquid crystal display element is mainly composed of three parts: a table 11, a friction roller 12 and a support. A friction roller 12 is configured, and the friction roller is centered on a horizontal axis, and its two ends are supported by brackets so that it can rotate along the axis. In this embodiment, the friction roller 12 is a hollow cylindrical member made of strong fiber plastic, especially carbon fiber reinforced plastic (CFRP). A layer of metal film is formed on the outer surface of the cylindrical member. On the surface of the metal film, an adhesive tape, especially a double-sided tape, is used to wrap the rubbing cloth (not shown in the figure).

[0024] It is satisfactory to use carbon fiber reinforced plastic (CFRP), which can make the friction roller 12 have a strength of 250Gpa in the long axis direction and 200Gpa in the vertical direction...

Embodiment 2

[0027]Embodiment 2: A method of manufacturing a liquid crystal display element. First, a transparent electrode is arranged on the surface of a pair of glass substrates, and an alignment film is formed on the transparent electrode. The alignment film is made of an organic polymer material, especially a glass substrate. Made of materials such as POLYAMIDE. Because in general, the glassy amite compound is insoluble in the solvent, anhydrous acid and di-amin (Di-amin) compound are reacted in the solvent to synthesize the glassy amide (POLYAMIDE) acid, usually with Polishing water (Varnish) for painting as a solution of POLYAMIDE acid. After being coated on a glass substrate, it is dehydrated and hardened into POLYAMIDE through a heating and hardening process. In more detail, use the above-mentioned glass submigram (POLYAMIDE) acid N-base (Methyl)-2 hydrate (Hydrlide) and other medium (Amid) polar solvents and banana water (Cellosolve, The molecular formula is: HOH 2 CCH 2 OC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com