Solid photogvapic taking cameva and mfg method thereof

A technology of a solid-state imaging device and a manufacturing method, which is applied in the fields of semiconductor/solid-state device manufacturing, electric solid-state device, image communication, etc., can solve the problem of difficulty in obtaining a solid-state imaging device with high light-gathering ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

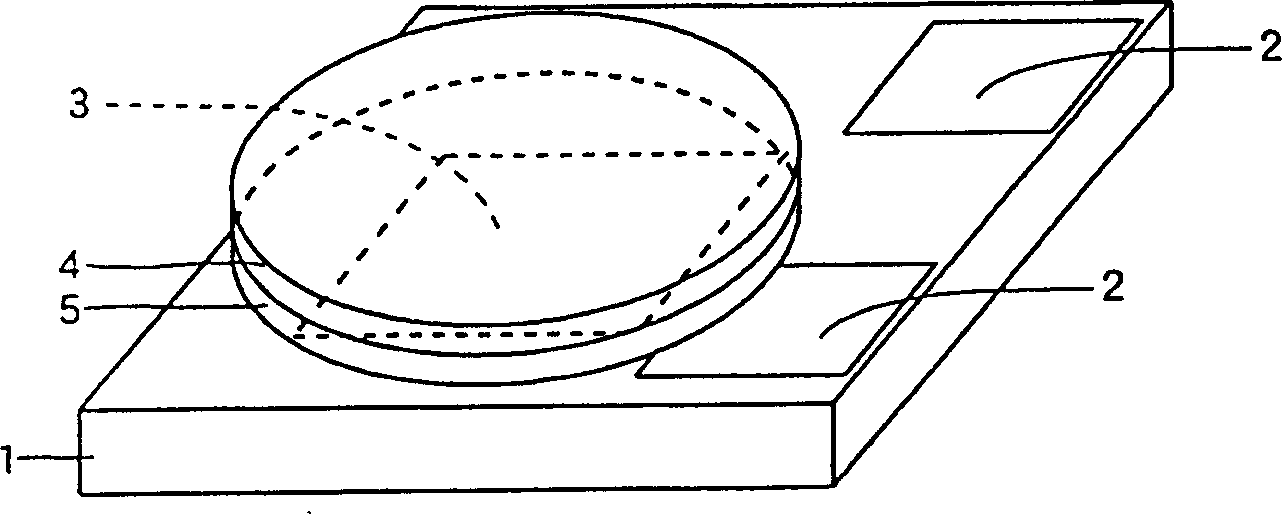

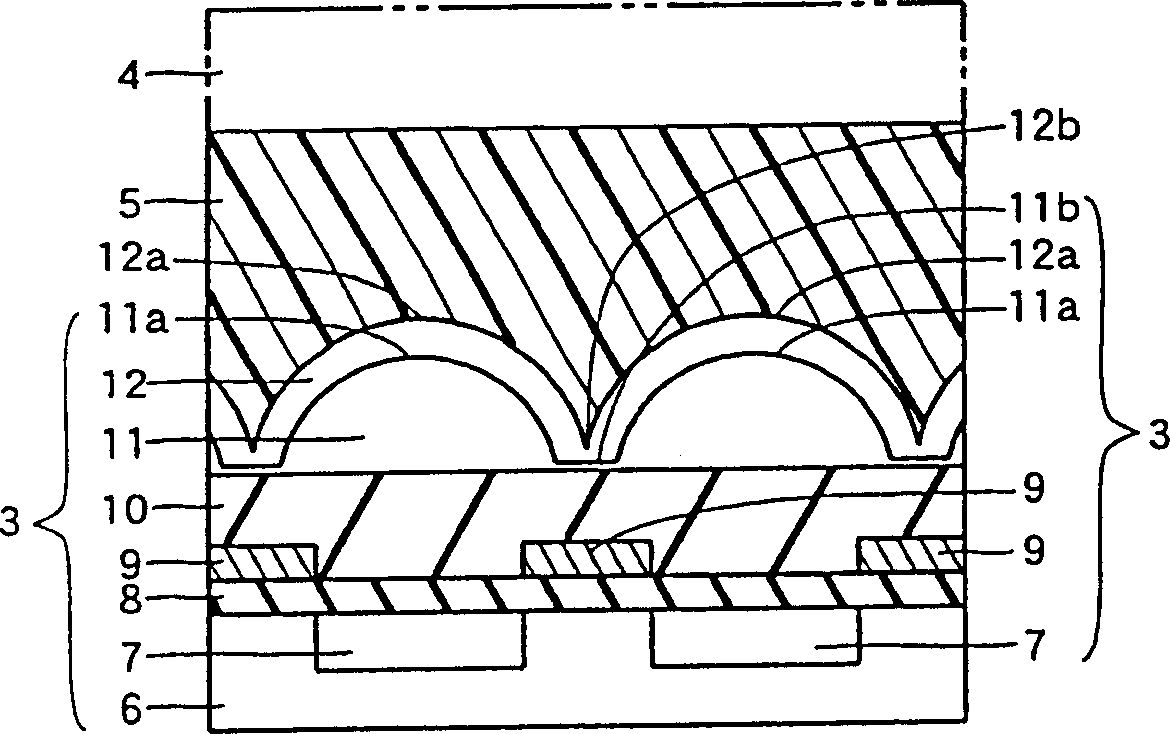

[0048] First, refer to figure 1 and figure 2 , the structure of the solid-state imaging device according to Embodiment 1 will be described.

[0049] Such as figure 1 As shown, in Embodiment 1, peripheral circuits 2 such as drivers and a solid-state imaging device 3 are assembled on a mounting substrate 1 . An optical lens 4 for collecting reflected light from a subject is integrally formed on the solid-state imaging element 3 via a resin layer 5 . The resin layer 5 is formed of epoxy resin with a thickness of about 1 mm to 2 mm, and has a refractive index of about 1.5.

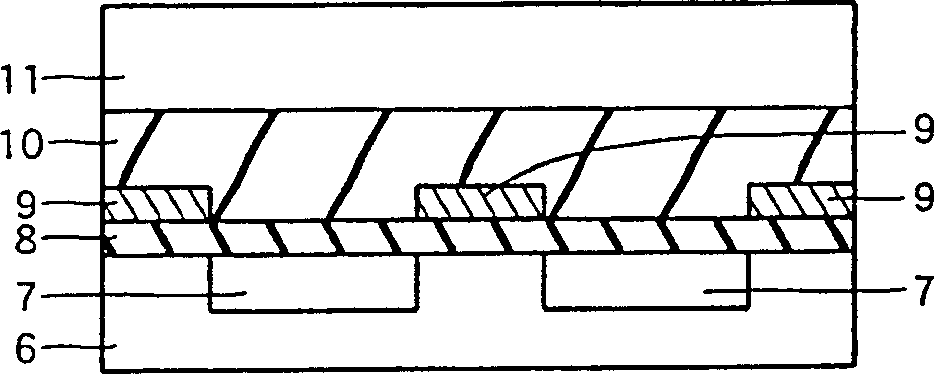

[0050] The specific structure of the solid-state imaging element 3 is as follows: figure 2 As shown, a light receiving portion 7 having a photoelectric conversion function of converting incident light into signal charges is formed on a predetermined region of the Si substrate 6 . On the Si substrate 6 on which the light receiving part 7 is formed 2 Interlayer insulating film 8 is formed to a thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com