Intermittent drip irrigation belt

A drip irrigation belt and tubular technology, which is applied in the field of intermittent drip irrigation belt, can solve the problems of easy blockage of the outlet flow channel, increased energy consumption and cost, unfavorable drip irrigation promotion, etc., and achieves less consumables, low production cost, and low precision requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

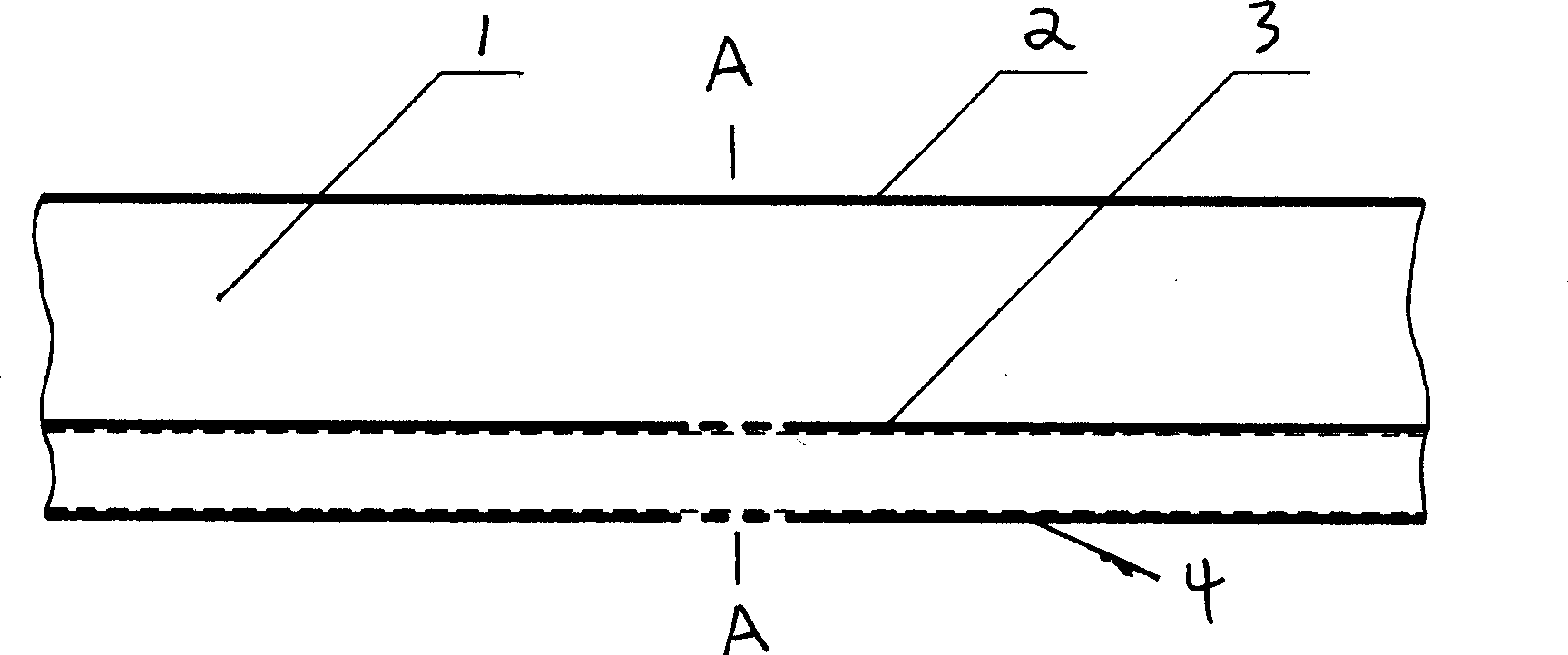

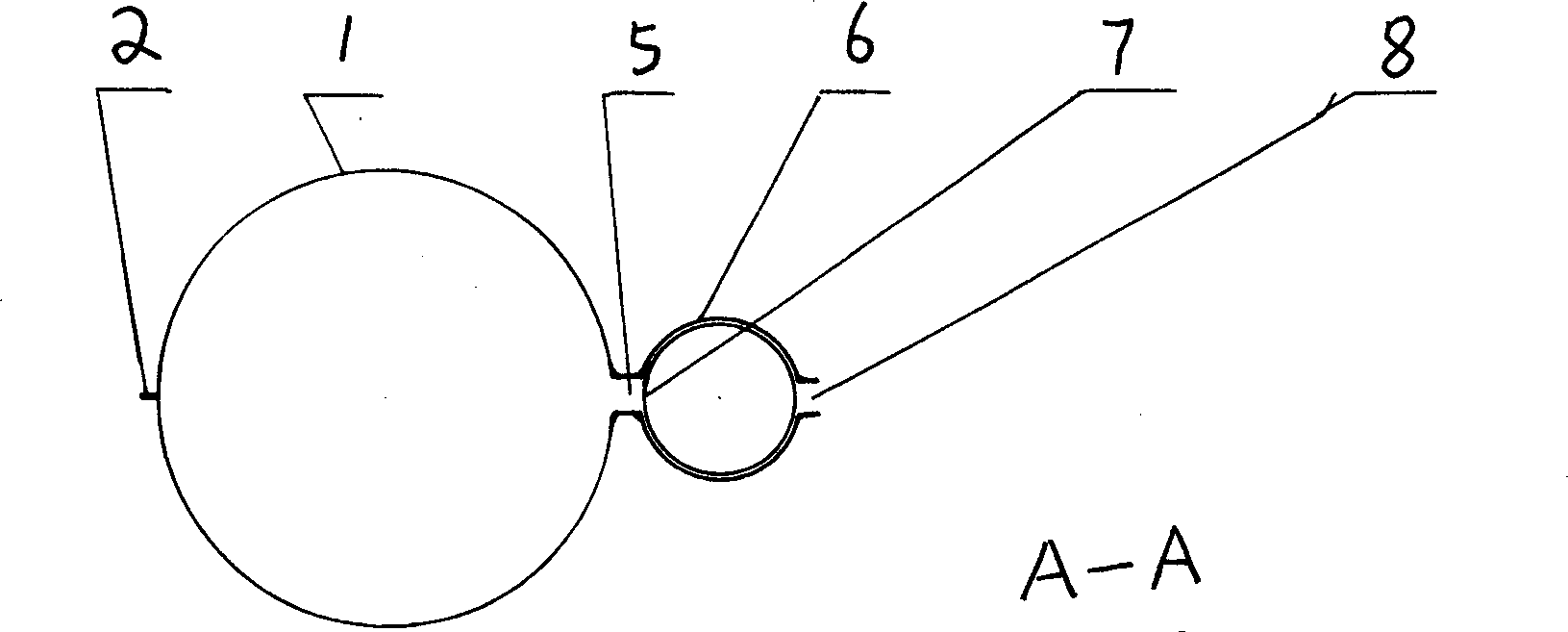

[0015] In Embodiment 1, the main pipe 1 is connected to the rubber tube valve, and the rubber tube valve is composed of a rubber tube valve core 7 and a valve sleeve, and the valve sleeve is composed of a thin film tube valve seat 6 and several pairs of water inlet and outlet. The water inlet 5, the film tube valve seat 6, the rubber tube spool 7 and the water outlet 8 form a valve unit, and several valve units form the rubber tube valve. The main pipe 1 and the valve sleeve of embodiment 1 can be welded together with two plastic films, figure 1 The thick solid lines 2, 3, and 4 are all welding lines, and the dotted line on the same line as the welding line is where the water inlet or water outlet is located. The film at the dotted line and its left and right sides can be properly stretched during the production process to ensure Widen the inlet and outlet. Embodiment 1 is a gravity water separation type intermittent drip irrigation belt, which must be placed on the ground or...

Embodiment 2

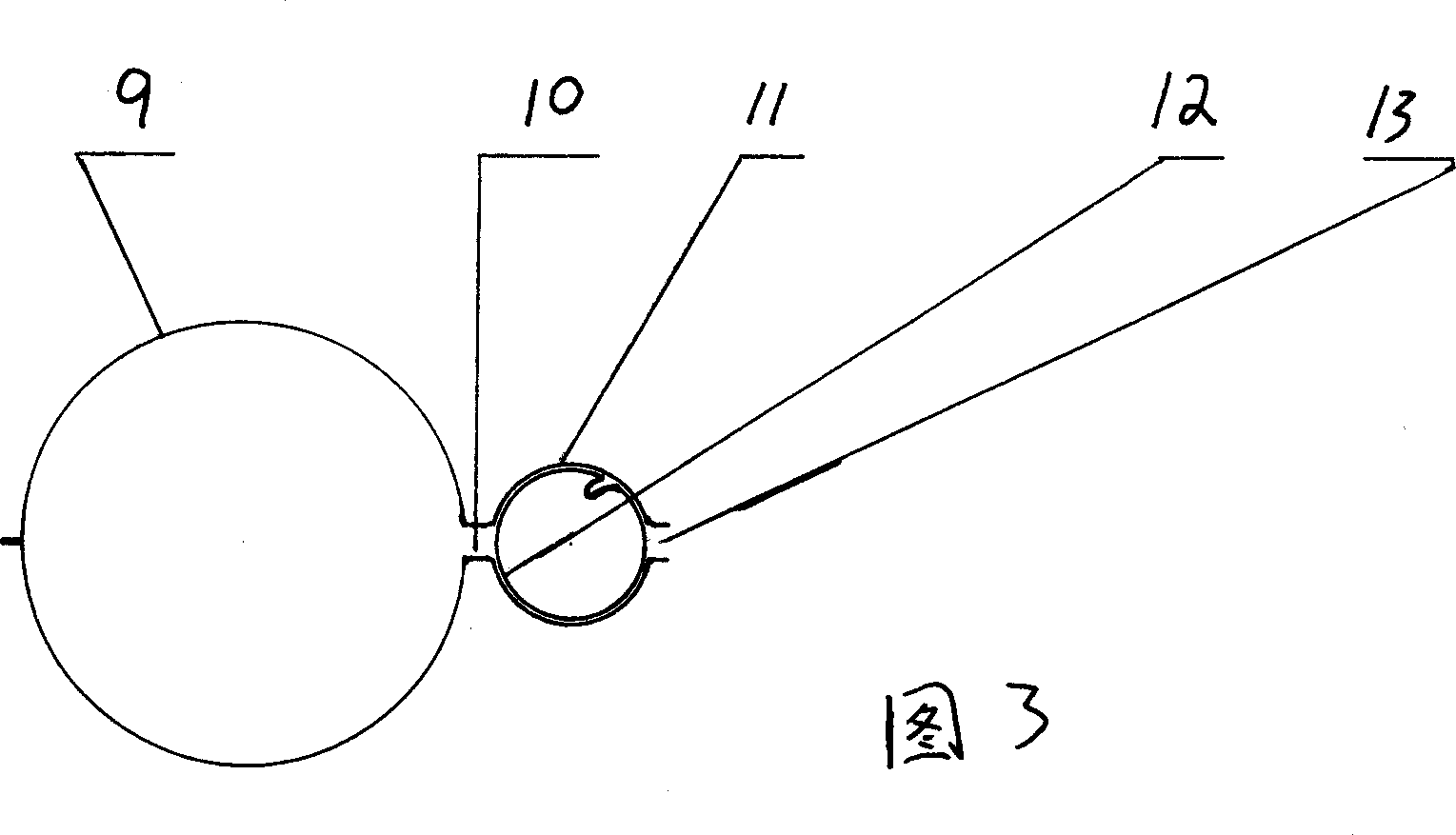

[0016] The difference between embodiment 2 and embodiment 1 lies in the valve core, the valve core of embodiment 2 is a film tube, and the valve core of embodiment 1 is a rubber tube. In embodiment 2, the main pipe 9 is connected to the membrane tube valve, and the membrane tube valve is composed of a membrane tube valve core 12 and a valve sleeve, and the valve sleeve is composed of a membrane tube valve seat 11 and several pairs of water inlet and outlet. Water inlet 10, film tube valve seat 11, film tube spool 12 and water outlet 13 constitute a valve unit, and several valve units just constitute a film tube valve. Embodiment 2 belongs to gravity water separation type intermittent drip irrigation belt, and its working principle is the same as that of embodiment 1.

Embodiment 3

[0017] In Embodiment 3, the main pipe 14 is connected to the diaphragm pipe valve, and the diaphragm pipe valve is composed of a diaphragm valve core 17 and a valve sleeve, and the valve sleeve is composed of a film tube and several pairs of water inlets and outlets. The lower wall 19 (valve seat) and the upper wall 15 constitute. Water inlet 16, upper wall 15, diaphragm spool 17, lower wall 19 and water outlet 18 constitute a valve unit, and several valve units constitute a diaphragm pipe valve. Embodiment 3 belongs to gravity water separation type intermittent drip irrigation belt, and its working principle is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com