High strength chemical fiber plastic-coated tarpaulin and the manufacturing method thereof

A high-strength, tarpaulin technology, used in railway car body parts, transportation and packaging, can solve the problems of poor tarpaulin overlap, short service life, high labor intensity, etc., to speed up railway transportation efficiency and easy operation. , The effect of improving loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

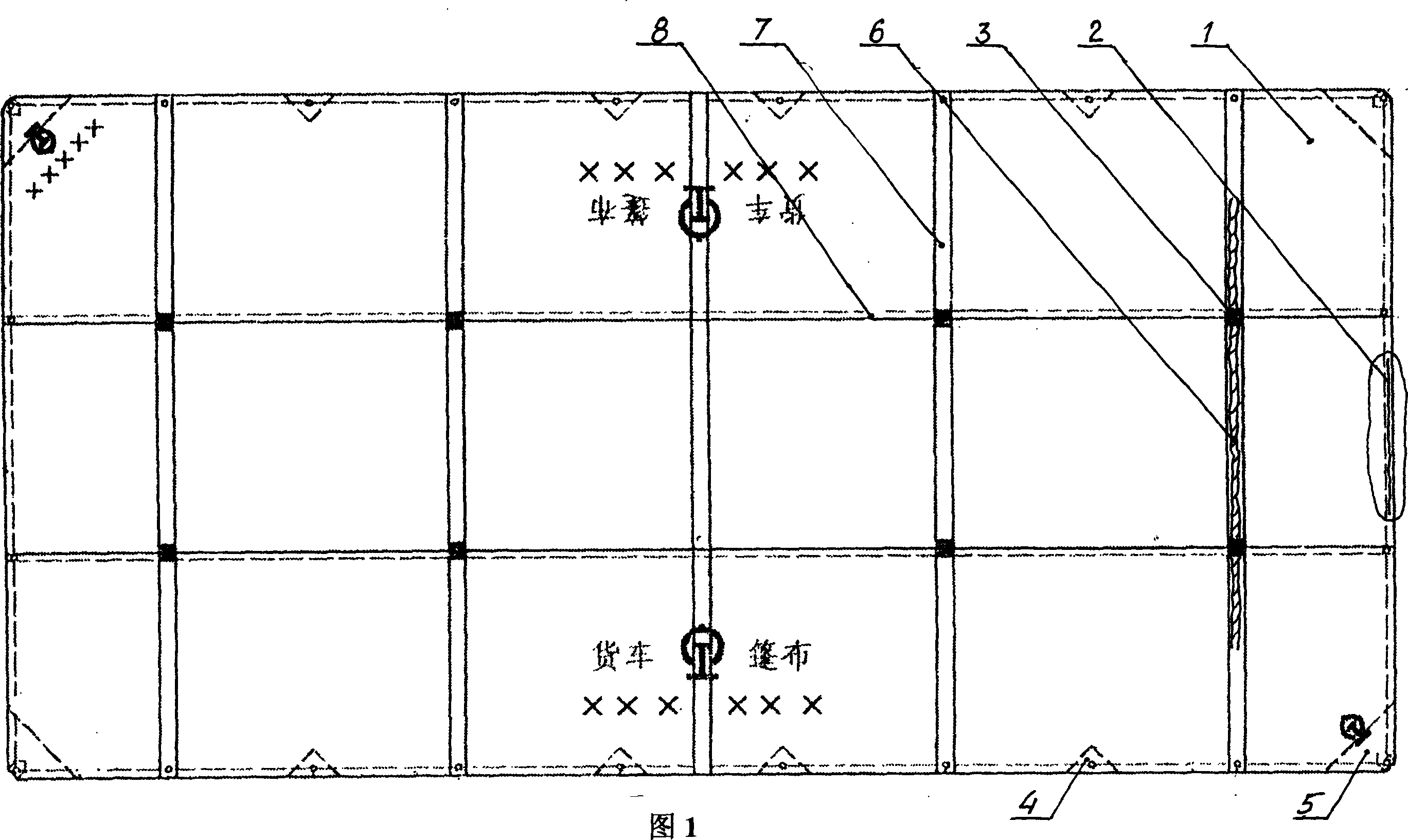

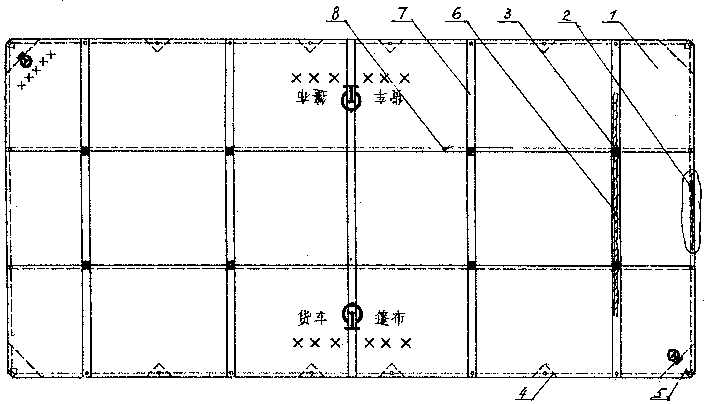

[0020] The best embodiment of the present invention will now be described in detail with reference to Figure 1:

[0021] A kind of high-strength chemical fiber plastic coated tarpaulin is shown in Figure 1. It is composed of a thatch cloth 1 and the edge rope 2 and waist rope 6 tied to it. The thatch cloth 1 is rectangular with three 17200×1833mm double-sided artificial leather. Frame 8 is connected, processed into an area of 94.6m 2 There is a hemming rope 2 on the periphery of the tom cloth, five reinforcing ribs 7 are arranged in the middle, a rope threading cloth 3 is arranged at the junction of the reinforcing ribs 7 and the panel 8, and a waist rope 6 is worn in the rope threading cloth 3 , There are big triangles 5 on the four corners of the thatch 1, and small triangles 4 on the long sides for reinforcement.

[0022] The base fabric of the double-sided artificial leather of the present invention adopts interwoven fabric 5732 or 5736, and the side rope and waist rope adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com