method for preparation of Sr titanate powder

A technology of strontium titanate powder and solution, which is applied in the direction of titanate, alkaline earth metal titanate, chemical instruments and methods, etc., and can solve the problems of powder quality difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

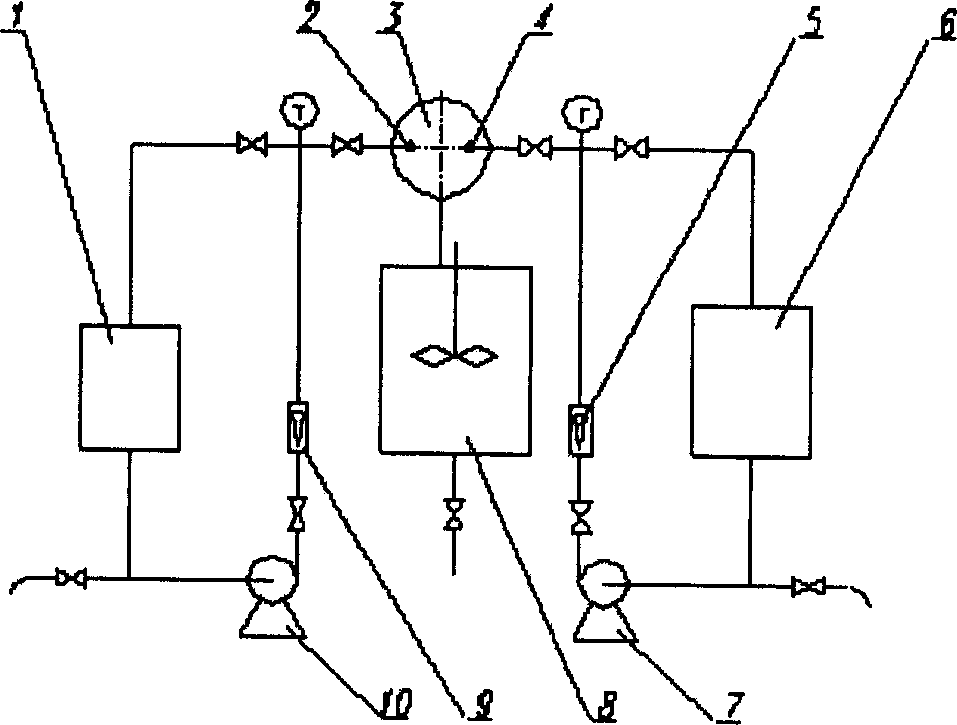

[0043] Prepare a NaOH solution with a concentration of 6.0 mol / L, wherein NaOH uses an analytically pure reagent. A NaOH solution with a concentration of 6 mol / l is placed in a stainless steel NaOH storage tank 1 . while SrCl 2 and TiCl 4 The preparation of the mixed solution adopts the following steps: respectively prepare 2.0mol / L concentration of SrCl 2 and 2.0mol / L concentration of TiCl 4 solution. Prepare [SrCl by adding deionized water 2 ]+[TiCl 4 ] The total concentration of the mixed solution is 1mol / L, while [SrCl 2 ] / [TiCl 4 ] is 1.05. The above prepared SrCl 2 and TiCl 4 The mixed solution is placed in storage tank 6.

[0044] After starting the hypergravity reactor, the total concentration of 1mol / L SrCl 2 and TiCl 4 The mixed solution is pumped out from the storage tank 6 through the pump 7, and after being measured by the flowmeter 5, enters the rotary bed 3 from the rotary bed liquid inlet 4, and its flow rate is set at 40 L / hr. The NaOH solution w...

Embodiment 2

[0049] Adopt the preparation method as described in embodiment 1, the NaOH aqueous solution that preparation concentration is 6.0mol / L, [SrCl 2 ]+[TiCl 4 ] The total concentration of the mixed solution is 1.0mol / L and [SrCl 2 ] / [TiCl 4 ] is 1.05 containing Ba 2+ and Ti 4+ of aqueous solution.

[0050] After starting the high gravity reactor, adopt the mode as embodiment 1 with SrCl 2 and TiCl 4 The mixed solution is pumped out from the storage tank 6 through the pump 7, and after being metered by the flowmeter 5, enters the rotary bed 3 at 80 L / hr from the rotary bed liquid inlet 4. Adjust the flow rate of the NaOH solution with a concentration of 6.0 mol / L into the rotary bed 3 to vary within the range of 40 L / hr to 90 L / hr. After entering the supergravity reactor, controlled at a reaction temperature of about 85°C, SrCl 2 and TiCl 4 The mixed solution and the NaOH solution fully contact and react in the packing layer of the rotary bed 3. During the reaction, the rota...

Embodiment 3

[0054] Adopt the method as embodiment 1, preparation concentration is the KOH aqueous solution of 8.0mol / L, [SrCl 2 ]+[TiCl 4 ] with a total concentration of 2mol / L and [SrCl 2 ] / [TiCl 4 ] is an aqueous solution of 1.05.

[0055] According to the steps described in Example 1, the reaction was carried out in a high-gravity reactor at a temperature of 70° C. to obtain a slurry containing strontium titanate powder.

[0056] The slurry obtained after the reaction is stirred and aged in a stirred tank for 3-20 minutes. Then the aged suspension was filtered and washed three times with deionized water at about 95 °C, and dried in a desiccator to obtain SrTiO 3 Powder.

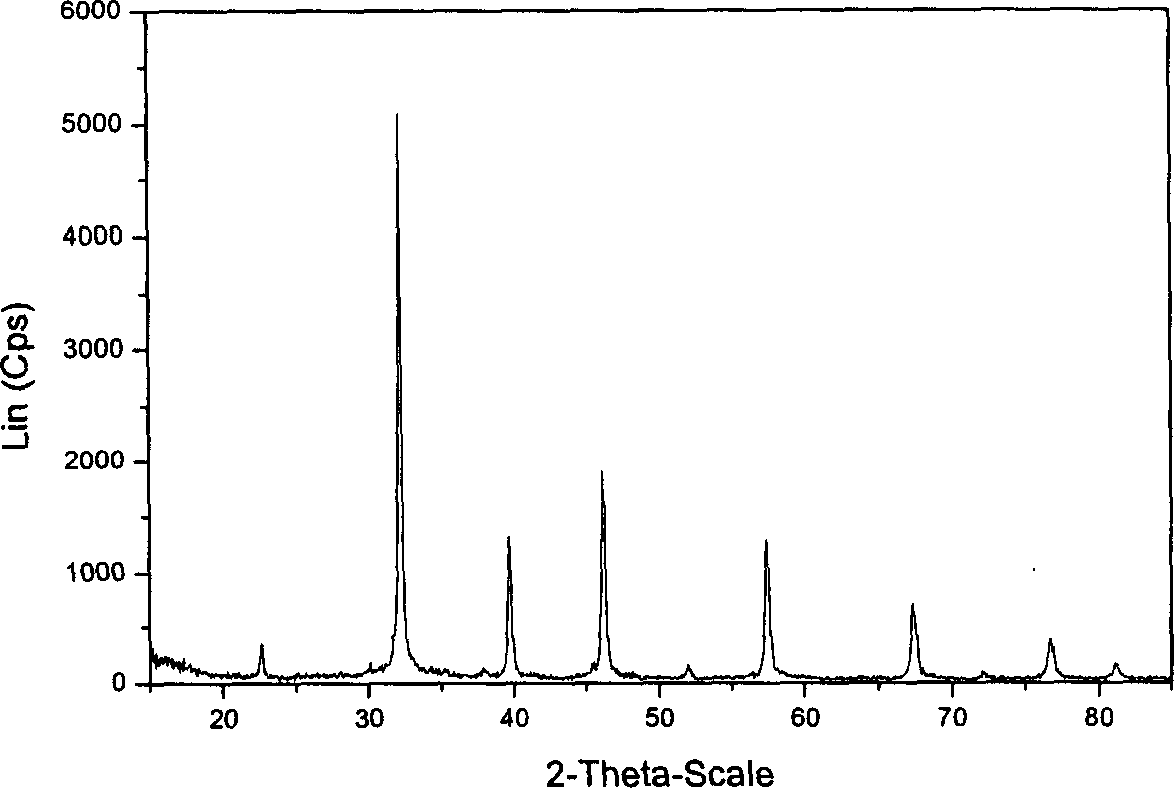

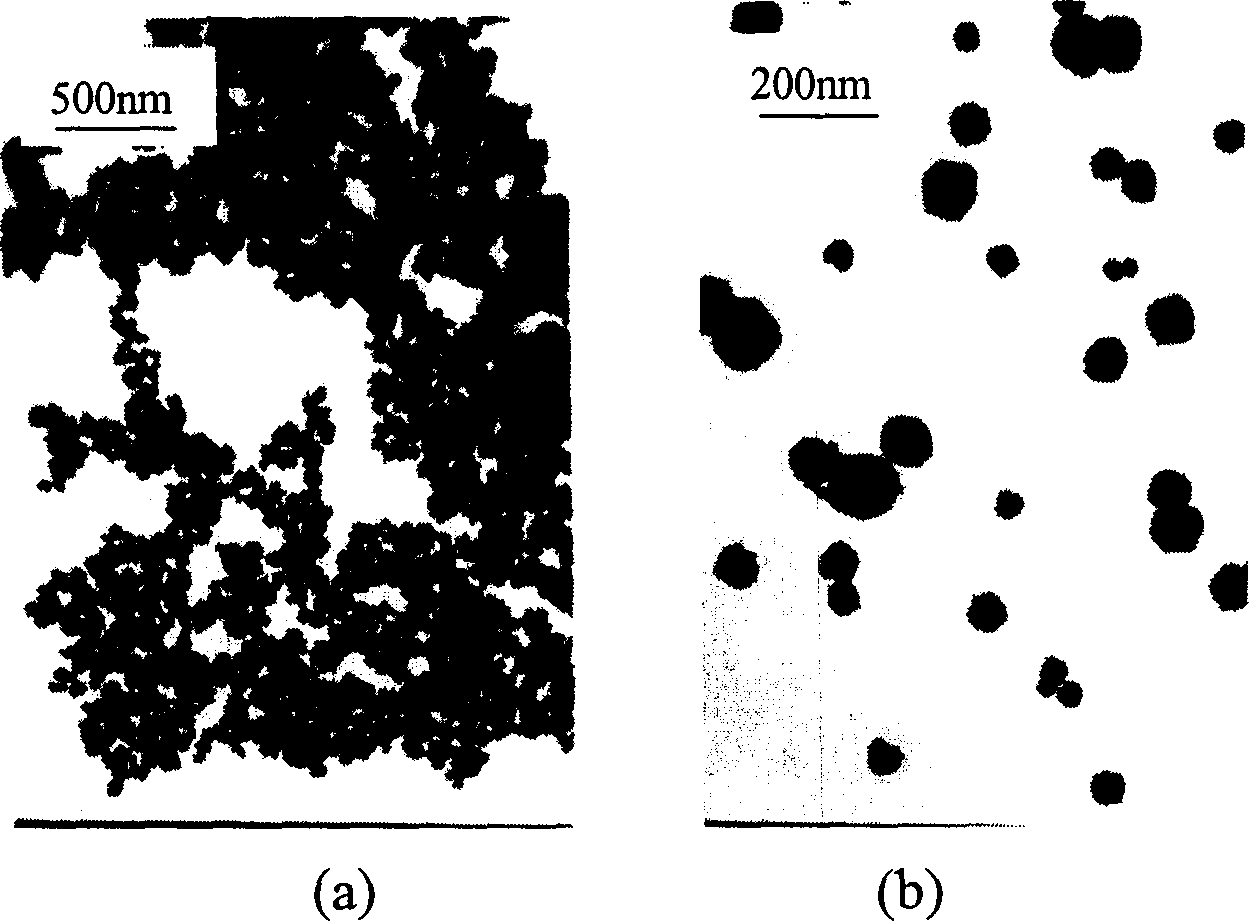

[0057] The analysis results show that the characteristics of the product obtained in this example are the same as those of the strontium titanate powder obtained in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com