Process flow for producing charcoal, coke, coal gas, and ceramic products using hazel rod coal resurgent gases technique

A technological process and regeneration gas technology, which is applied in coking ovens, biofuels, petroleum industry, etc., can solve the problems of not being able to use it and making it into machine-made charcoal, so as to protect resources, prevent environmental pollution, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

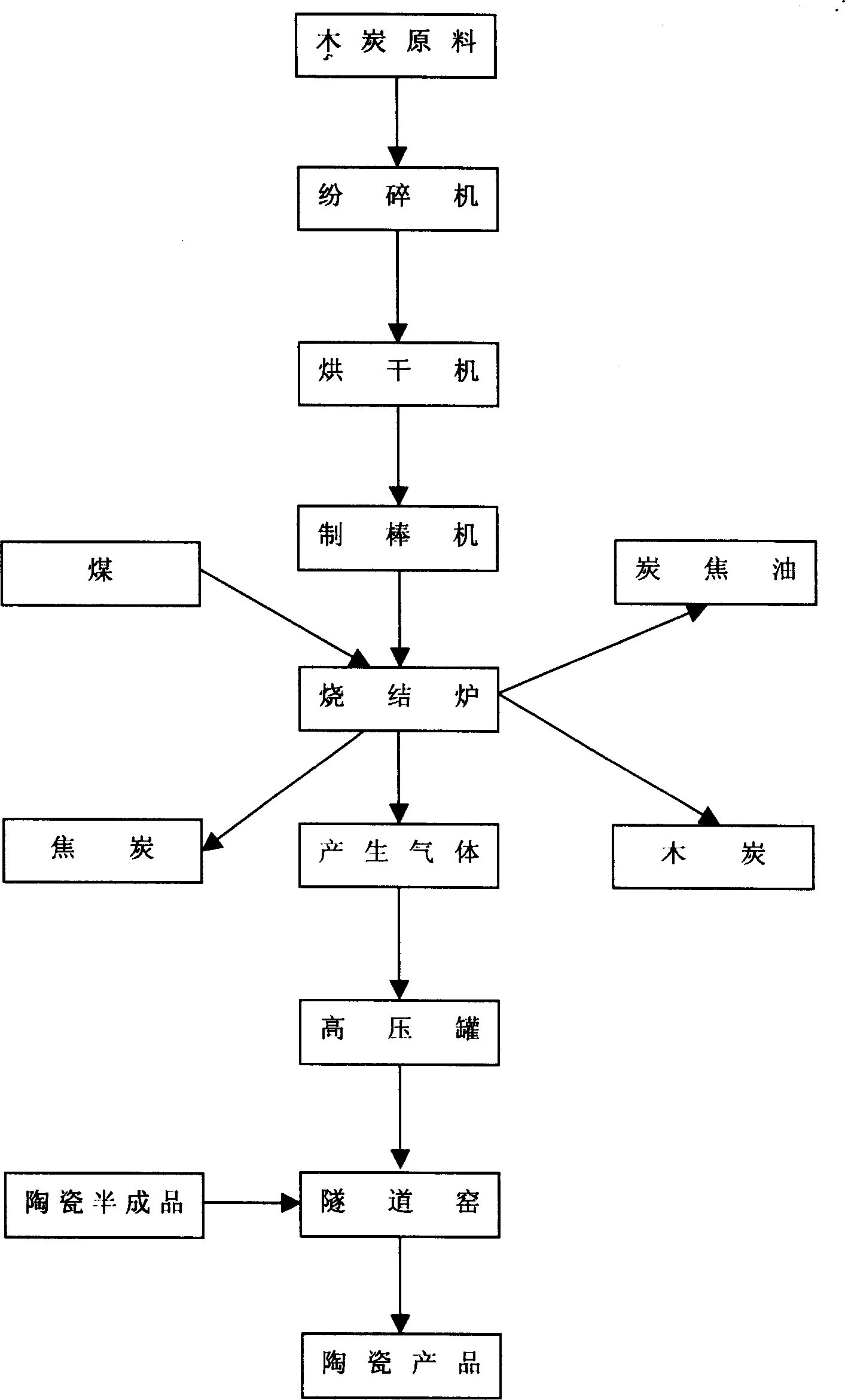

[0016] Below in conjunction with accompanying drawing, concrete technical scheme of the present invention is described further:

[0017] As shown in the attached figure, the technological process of producing charcoal, coke, gas and ceramic products by this hazel stalk coal regeneration gas technology uses discarded hazel stalks and hazel skins as raw materials, sorting, screening, sorting out sundries, and then crushing Granular, with a particle size of 2-3mm. The moisture content of the mixture of hazel stalk and hazel skin is generally 10-30% according to its freshness. After drying the mixture of hazel stalk and hazel skin in a dryer, [ Its water content is controlled below 5%] and sent to the charcoal machine with a working pressure of 200 tons and a working temperature of 500-1000°C to produce a carbon rod with a length of 600mm and a diameter of 5cm, and then send the prepared carbon rod into the carbonization furnace , the sintering temperature is 400-450°C, the time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com