Chips for beam-film integrated arrangement resonant beam pressure sensing device and manufacturing method thereof

A technology of pressure sensor and manufacturing method, which is applied in the direction of force measurement by measuring the frequency change of the stressed vibrating element, and can solve the problems affecting beam vibration, adhesion, not small, at least greater than the thickness of the sacrificial layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

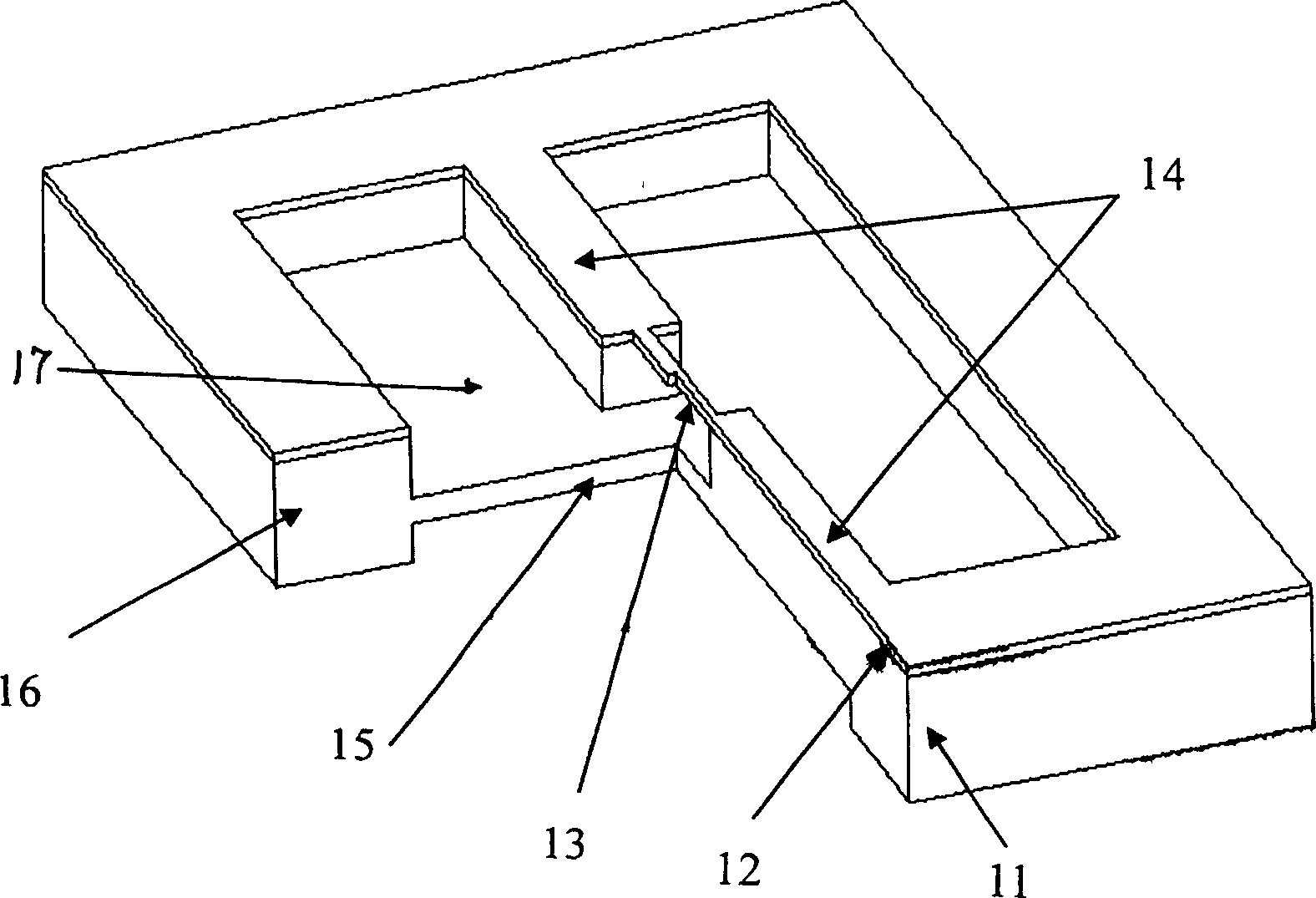

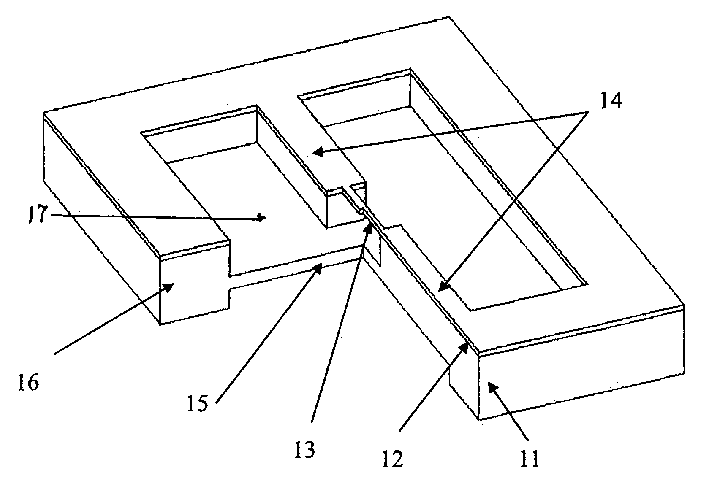

[0026] see figure 1 As shown, a resonant beam pressure sensor chip with a beam-membrane integrated structure of the present invention includes:

[0027] A silicon chip 11, on the silicon chip 11, one layer of silicon nitride film 12 is made, and described silicon chip 11 is a low-resistivity monocrystalline silicon chip; Described silicon nitride film 12 is the low pressure chemical vapor deposition LPCVD growth. Stressed thick silicon nitride, 2 microns thick or more.

[0028] A groove 17 is formed on the silicon nitride film 12 and the silicon wafer 11. The groove 17 is approximately I-shaped, forming two rectangular peninsulas 14, and the silicon nitride 12 on the two rectangular peninsulas 14 is connected to form a resonant beam 13; The peninsula 14 is in the shape of a cuboid, and its width is more than three times that of the resonant beam 13 .

[0029] The groove 17 on the silicon wafer 11 is surrounded by a rectangular frame 16 , and the bottom of the groove 17 is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com