Green phosphor of spherical RE phosphate and its prepn

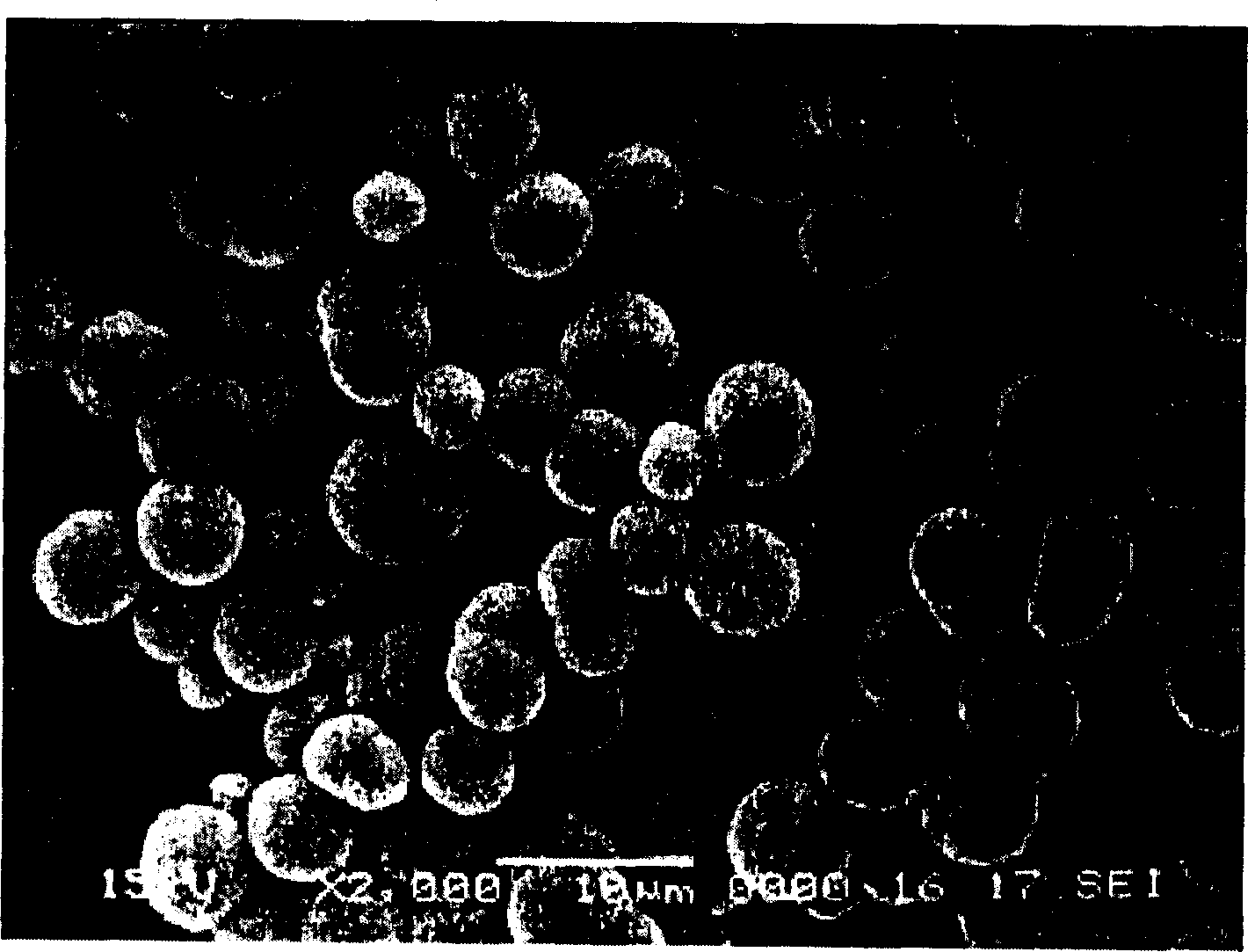

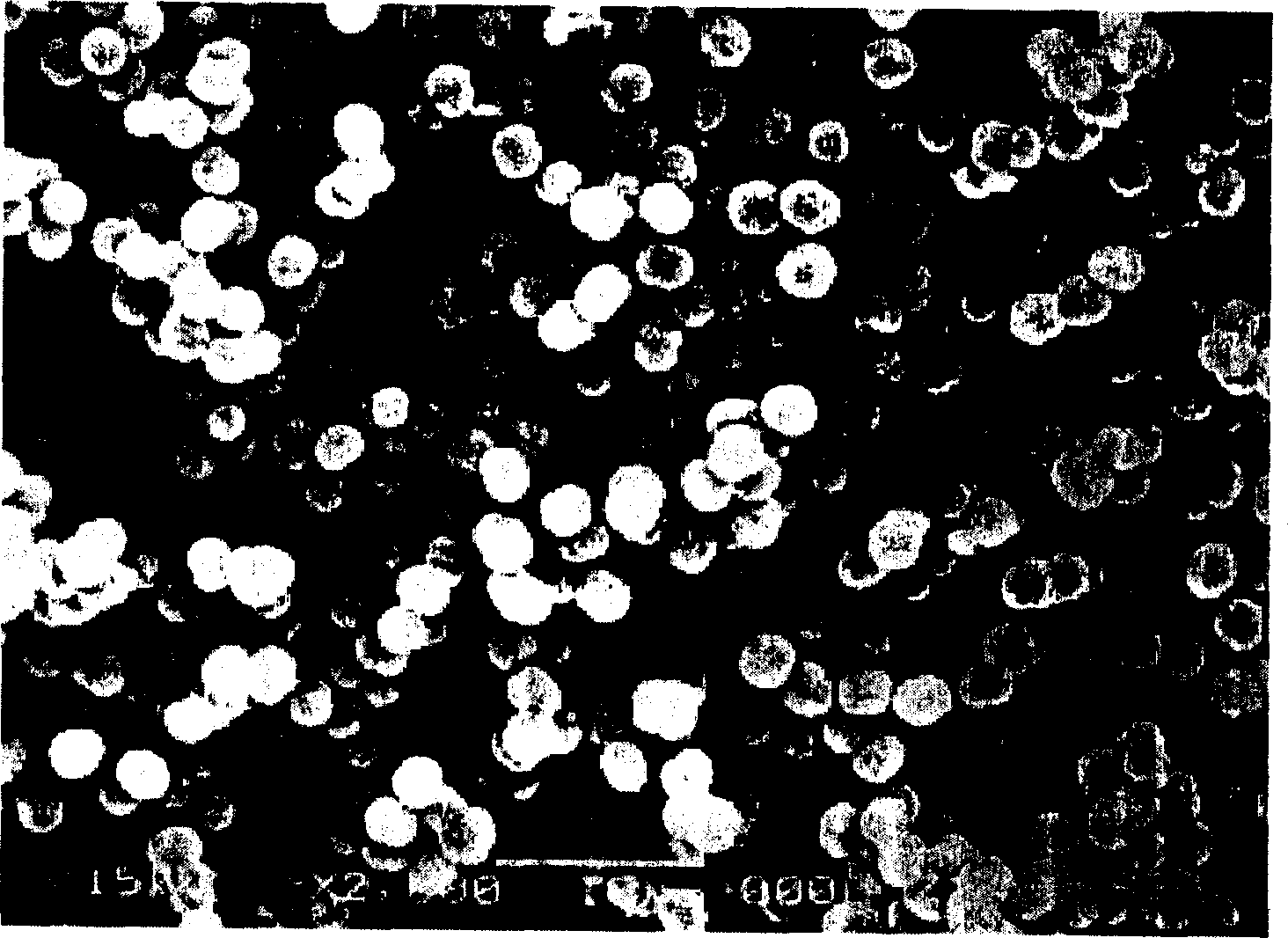

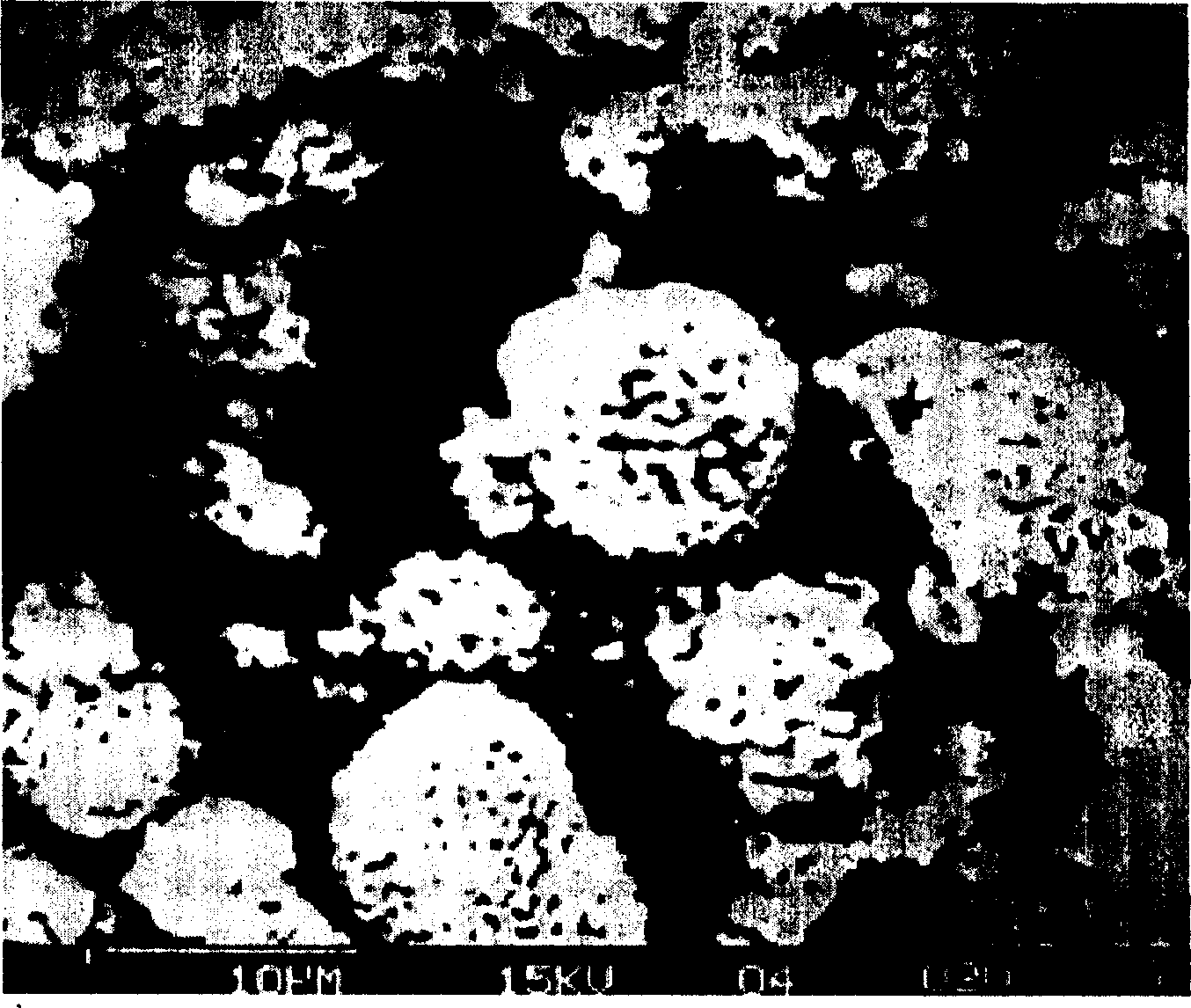

A technology of rare earth phosphate and green fluorescent powder, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problem of small fluorescent powder, and achieve the effect of regular particle shape, uniform size distribution, and good optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 65.16g La 2 o 3 , 68.84 CeO 2 , 37.38 Tb 4 o 7 , dissolved in hot 65% concentrated H3NO 3 250ml, add 20ml 35% H 2 o 2 , so that Ce 4+ All converted to Ce 3+ . Heat until clear, then dilute to one liter. The mixed rare earth concentration is 1mol / l. Another weighed (NH 4 ) 2 HPO 4 145.26g, dissolved and diluted to one liter, (NH 4 ) 2 HPO 4 The concentration of the solution is 1.1mol / l, the base solution is 100ml deionized water, and 3g of citric acid is added. Add the mixed rare earth nitrate and diammonium hydrogen phosphate solution into the bottom liquid in parallel, stir, and control the reaction temperature to 8°C and pH to 2.5. After the addition, the solution was aged at 50° C. for 10 h, and 2 ml of 3% PVA solution was added during the aging period. The precipitate was filtered, washed and dried. Add Li to the above mixed rare earth phosphate powder 2 CO 3 2.0g, H 3 BO 3 62g, mix well, and pretreat at 900°C for 2 hours. Cool, then...

Embodiment 2

[0041] Weigh 65.16g La 2 o 3 , 68.84 CeO 2 , 37.38 Tb 4 o 7 , dissolved in hot 65% concentrated H 3 NO 3 250ml, add 20ml 35% H 2 o 2 , so that Ce 4+ All converted to Ce 3+ . Heat until clear, then dilute to one liter. The mixed rare earth concentration is 1mol / l. Another weighed (NH 4 ) 2 HPO 4 145.26g, dissolved and diluted to one liter, (NH 4 ) 2 HPO 4 The concentration of the solution is 1.1mol / l, the base solution is 100ml deionized water, and 3g of citric acid is added. Add the mixed rare earth nitrate and diammonium hydrogen phosphate solution into the bottom liquid in parallel, stir, and control the reaction temperature to 15°C and pH to 3.0. After the addition, the solution was aged at 60° C. for 5 h, and 2 ml of 3% PVA solution was added during the aging. The precipitate was filtered, washed and dried. Add Li to the above mixed rare earth phosphate powder 2 CO 3 2.0g, H 3 BO 3 83g, mix well, and pretreat at 900°C for 2 hours. Cool, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com