Coating template calibrating device and method for sputtering nano multilayer film

A nano-multilayer, template technology, applied in sputtering, coating, metal material coating process, etc., can solve the problem of small color and gloss contrast, unclear boundary of positioning graphic film, increase template processing cost and difficulty, etc. problems, to reduce the processing cost and difficulty, improve the integrity rate and performance, and achieve the effect of a reliable preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

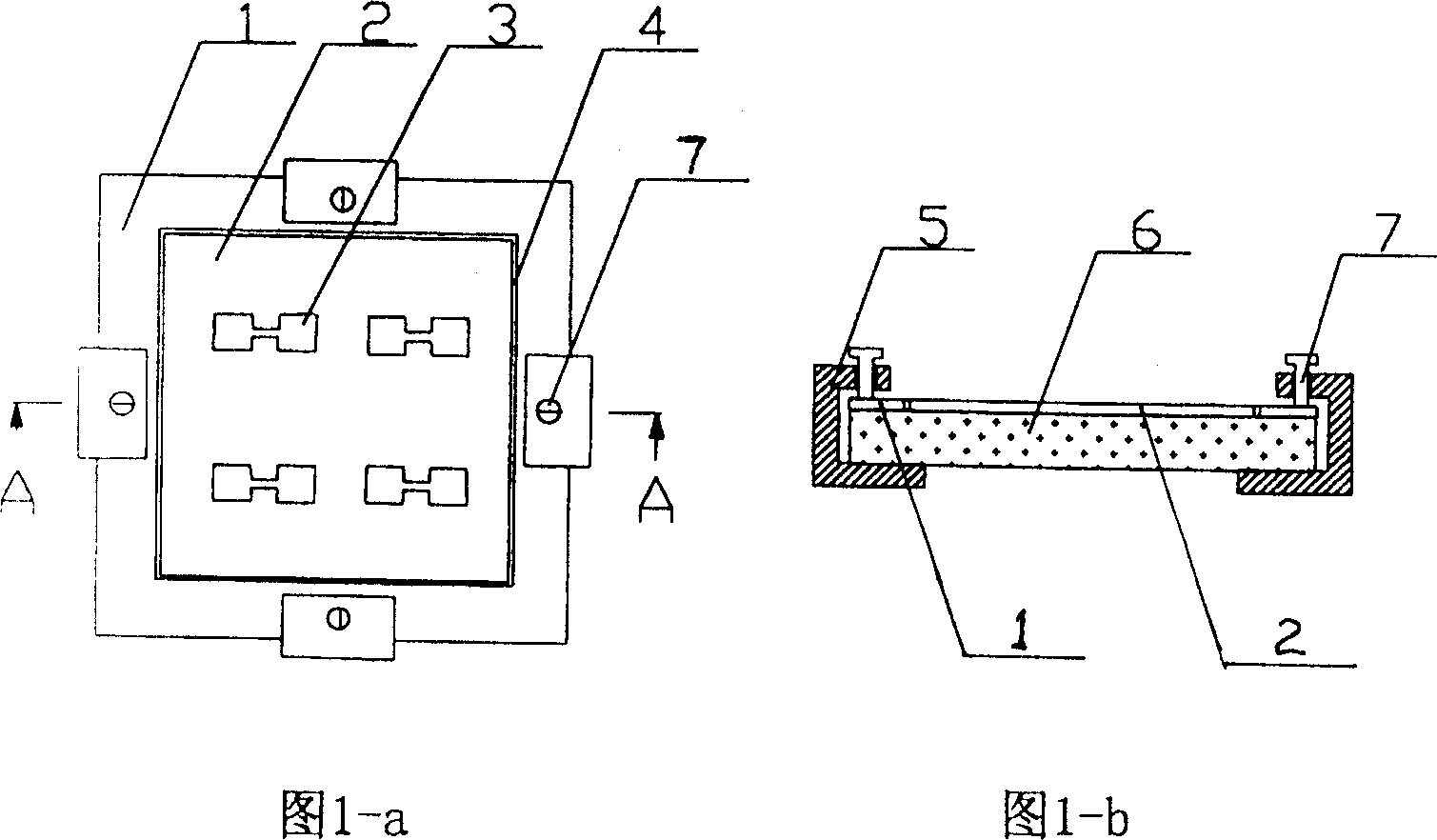

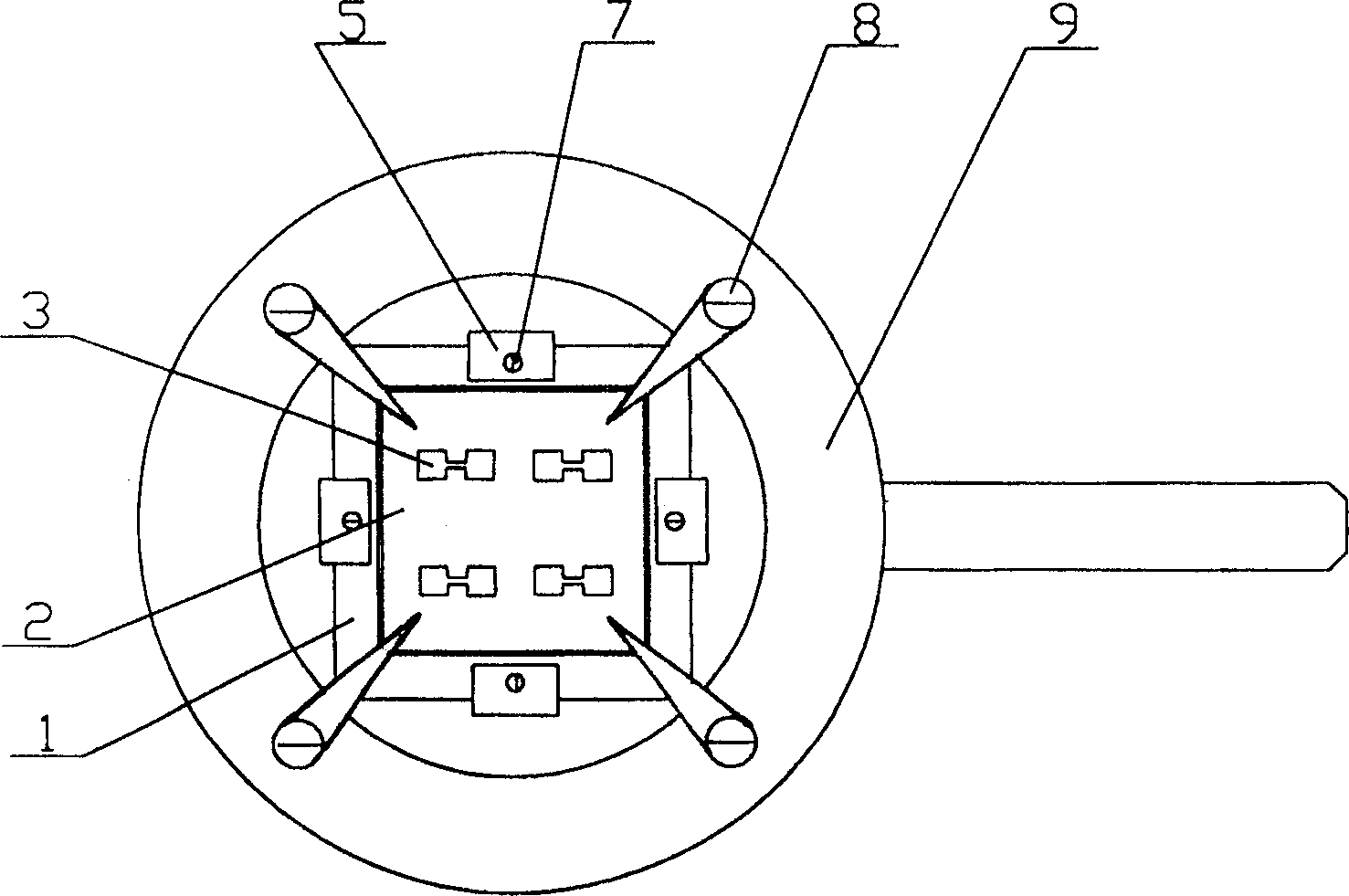

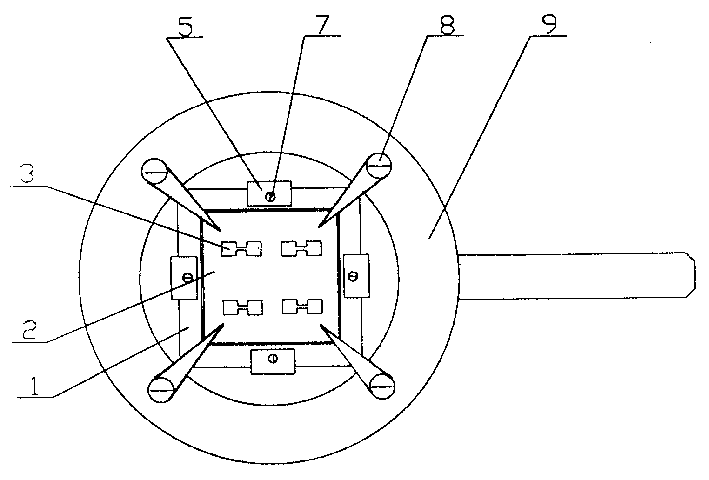

[0014] Embodiment: a kind of registration device (see figure 1 -a, figure 1 -b, figure 2 ), is characterized in that it is made of sample holder 9, spring clip 8, template 2, substrate 6, registration frame 1, substrate and copper clip 5 of registration frame and jacking bolt 7, said The registration frame 1 is placed on the sample holder 9 and fixed by the spring clip 8. The registration frame 1 is a frame with a certain width cut along the periphery of the template blank, and the cut part with the sputtering pattern is the template 2 , the registration frame 1 and the substrate 6 are placed in the copper clip 5, and are fixed by the tightening bolts 7, the template 2 with the sputtering pattern 3 is placed in the registration frame 1, and the template with the sputtering pattern 3 There is a gap 4 between 2 and the registration frame 1.

[0015] The materials of the template 2 and the registration frame 1 in the registration device mentioned above should be tough, easy t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com