Honeycomb can-type hollow fiber membrane separating equipment

A technology for separation equipment and fiber membranes, applied in semipermeable membrane separation, membrane technology, permeation/dialysis water/sewage treatment, etc., can solve the problem of reducing the surface scouring performance of hollow fiber membranes, high cost of purification and separation equipment, and waste of financial and material resources and other problems, to achieve the effect of eliminating dripping and cross-connection of running caps, eliminating adverse influencing factors, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

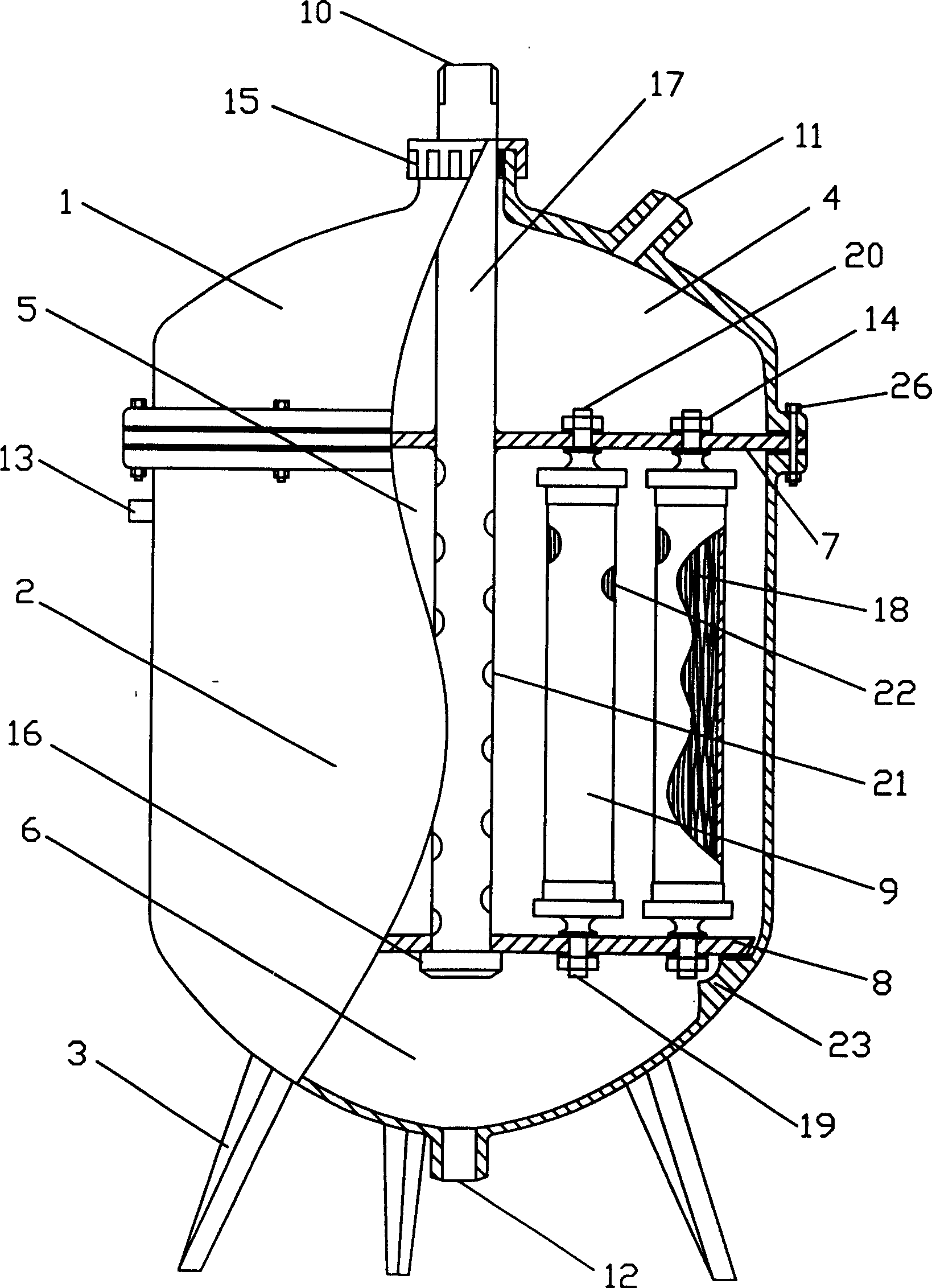

[0019] Figure number

[0020] 1. Can cap 2. Can body 3. Can foot

[0021] 4. Upper tank room, 5. Middle tank room 6. Lower tank room

[0022] 7. Upper partition 8. Lower partition

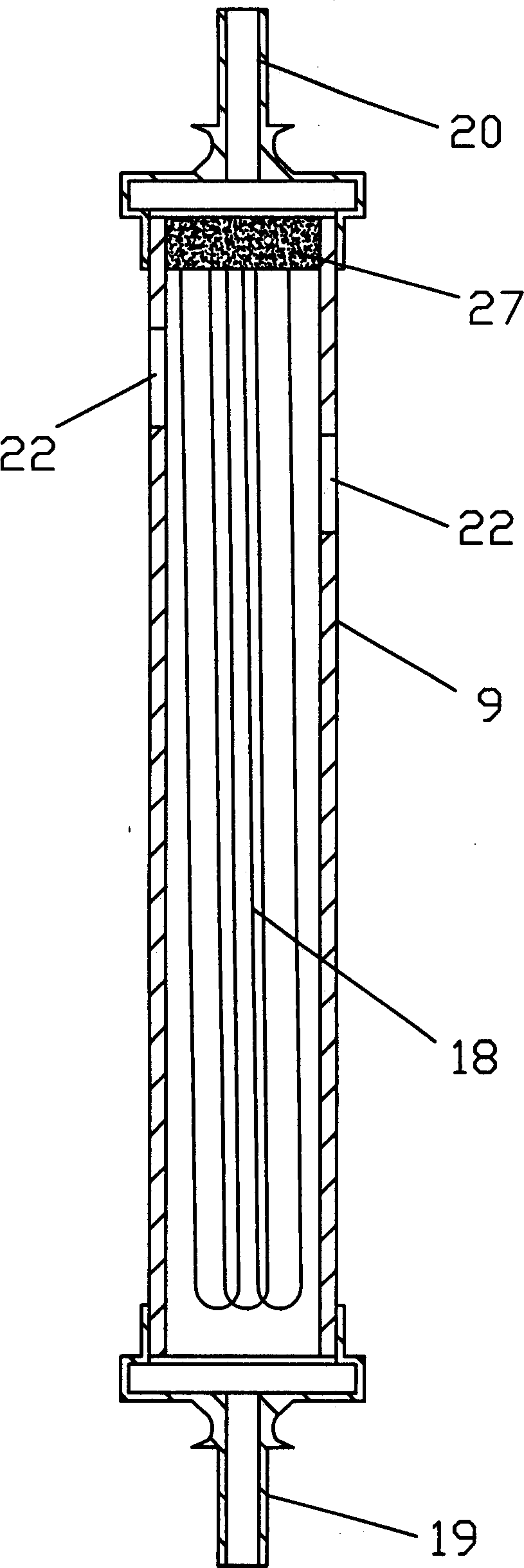

[0023] 9. Hollow fiber membrane module 10. Raw (material) liquid inlet

[0024] 11. Permeate total outlet 12. Concentrate total outlet (high pressure gas inlet)

[0025] 13. Exhaust port 14. Nut 15. Nut

[0026] 16. Nut 17. Center tube

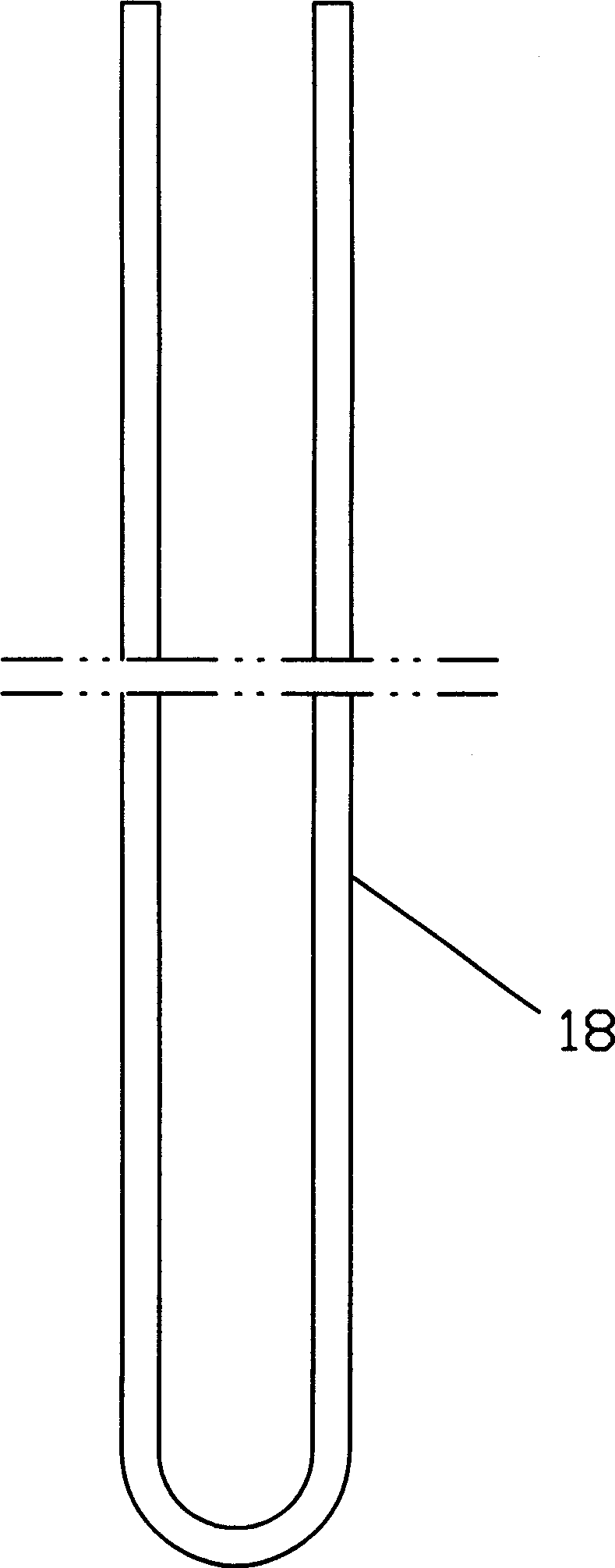

[0027] 18. U-shaped hollow fiber membrane 19. Concentrate outlet 20. Permeate outlet

[0028] 21. Through hole 22. Inlet hole 23. Ring platform

[0029] 24. Center hole 25. Round hole 26. Bolt

[0030] 27. Epoxy resin 28. Raw (material) liquid supply pipe 29. Liquid pump

[0031] 30. Raw (material) liquid tank 31. Permeate liquid outlet pipe 32. Gas supply pipe

[0032] 33. Air pump 34. Concentrate outlet pipe 35. Check valve

[0033] 36. Exhaust pipe 37. Exhaust valve 38. Bypass pipe

[0034] 39. Drain valve 40. Return pipe

[0035] T1. Clock controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com