Light-emitting diode structure

A technology of light-emitting diodes and boron phosphide, applied in lasers, semiconductor devices, phonon exciters, etc., can solve problems such as high manufacturing costs, difficult manufacturing processes, and poor luminous efficiency of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

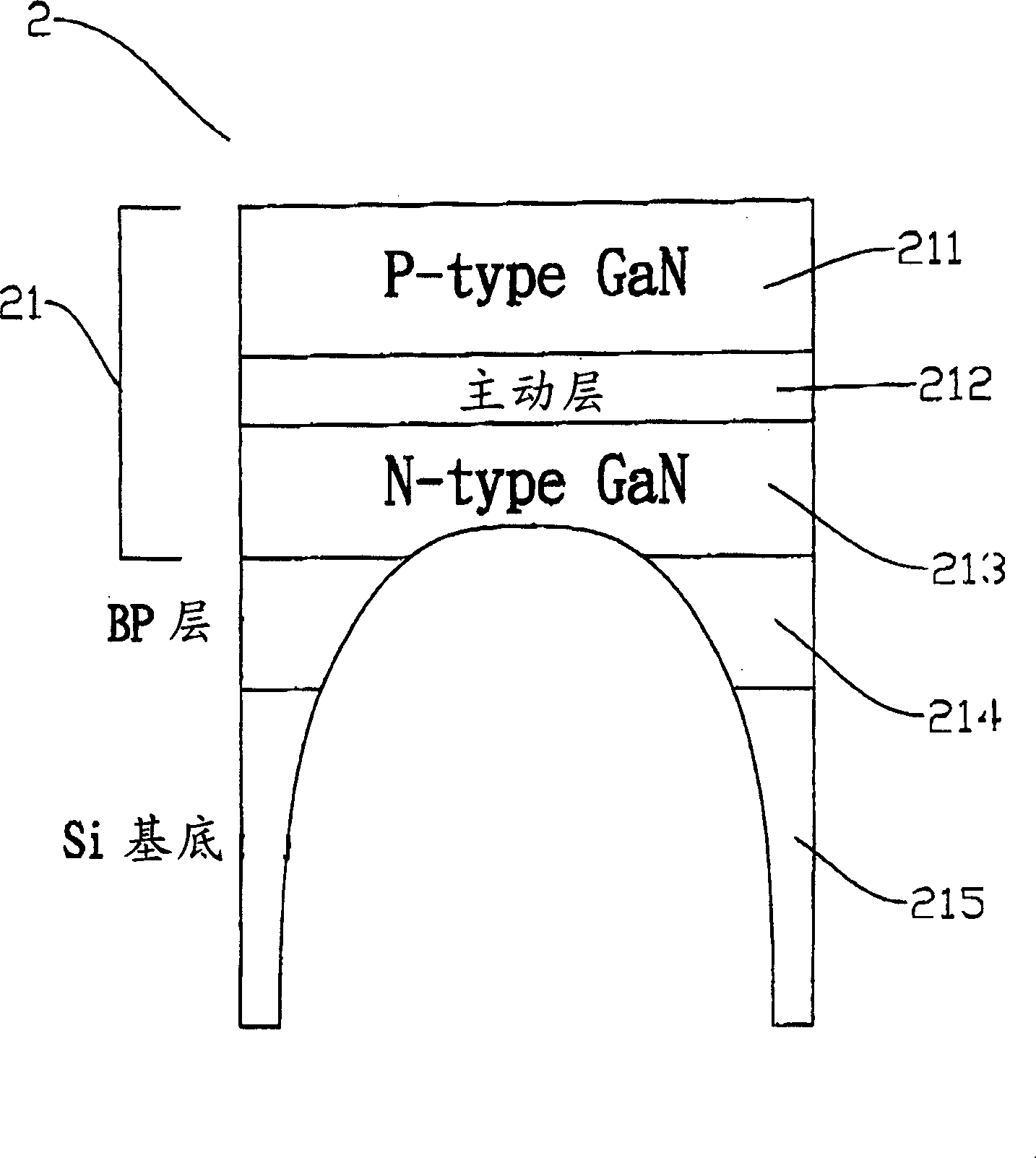

Embodiment 1

[0040] 21: components (devices)

[0041] 211: Second confinement layer (P-type GaN layer)

[0042] 212: Active layer

[0043] 213: The first confinement layer (N-type GaN layer)

[0044] 214: Boron monophosphide layer

[0045] 215: Silicon substrate (Si(100) substrate)

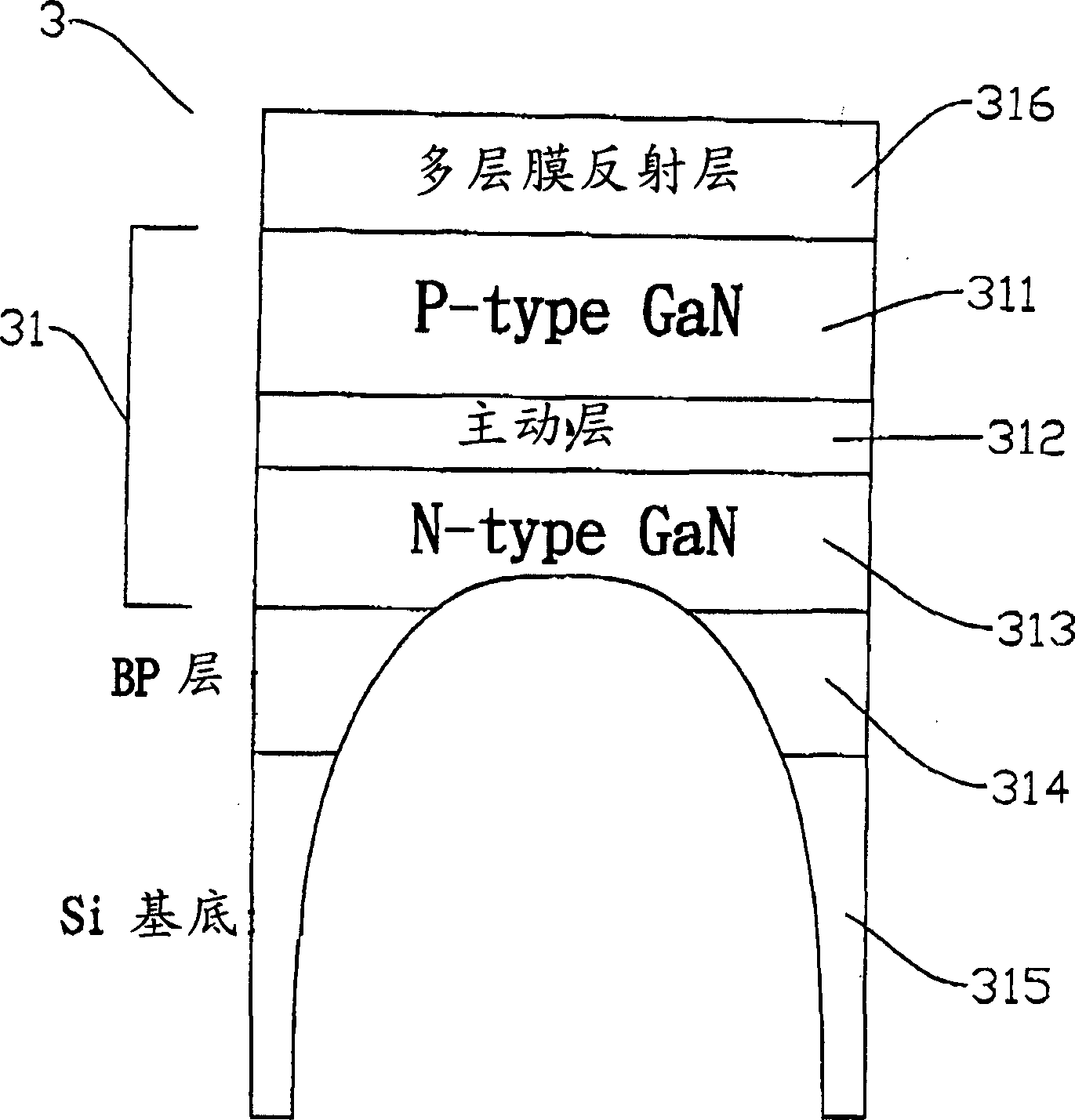

Embodiment 2

[0047] 31: components (devices)

[0048] 311: Second confinement layer (P-type GaN layer)

[0049] 312: Active layer

[0050] 313: The first confinement layer (N-type GaN layer)

[0051] 314: Boron monophosphide layer

[0052] 315: Silicon substrate (Si(100) substrate)

[0053] 316: Multilayer reflective mirror (reflecting mirror)

Embodiment 3

[0055] 41: components (devices)

[0056] 411: Second confinement layer (P-type GaN layer)

[0057] 412: Active layer

[0058] 413: The first confinement layer (N-type GaN layer)

[0059] 414: Boron monophosphide layer

[0060]415: Silicon substrate (Si(100)substrate)

[0061] 417: Micro-lens

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com