Method for preparing nanometre structure medicine

A nanostructure and drug technology, applied in the directions of pharmaceutical formulations, medical preparations of inactive ingredients, liposome delivery, etc., can solve the problems of affecting the preparation effect, a large number of foams, difficult to solve, etc., and achieve a simple, convenient and repeatable preparation process. High performance and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

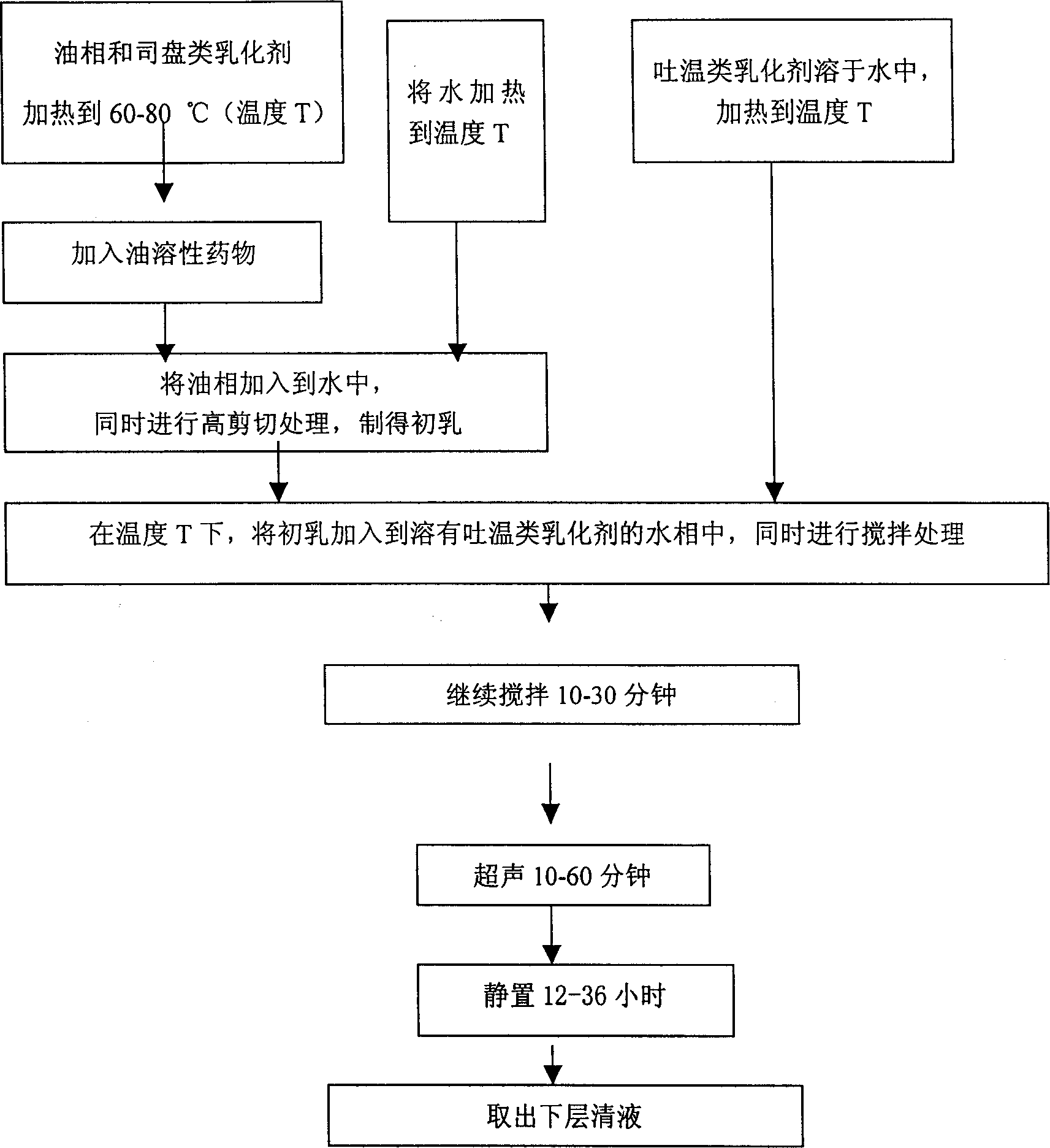

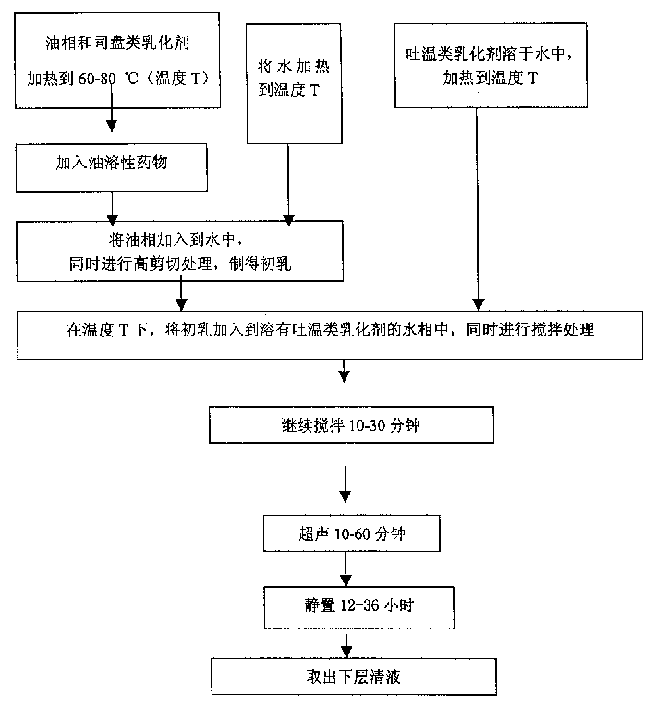

[0027] 1. Mix 0.2 grams of oil phase (containing 0.16 grams of soybean oil and 0.04 grams of stearic acid) with 1.0 grams of Span 80, heat to 65°C to become a molten liquid, and add 2.0 milligrams of retinoic acid to dissolve.

[0028] 2 Add the mixture obtained in step 1 into 150 ml of distilled water at 65°C, and simultaneously use a high-shear homogenizer for high-shear treatment to obtain colostrum.

[0029] 3 Dissolve 3.0 g of Tween 80 in 50 ml of distilled water and heat to 65°C, add colostrum, stir with a magnetic stirrer for 10 minutes, and then use an ultrasonic cleaner for 30 minutes of ultrasonic treatment.

[0030] 4 Put the mixture obtained in step 3 in a separatory funnel and let it stand for 12 hours, take out the lower layer and freeze-dry it to obtain the desired NLC.

Embodiment 2

[0032] 1 1.0 g of oil phase (containing 0.8 g of soybean oil and 0.2 g of stearic acid) is mixed with 1.0 g of Span 80, heated to 65°C to become a molten liquid, and 8.0 mg of retinoic acid is added to dissolve.

[0033] 2 Add the mixture obtained in step 1 into 150 ml of distilled water at 65°C, and simultaneously use a high-shear homogenizer for high-shear treatment to obtain colostrum.

[0034] 3 3.0 g of Tween 80 was dissolved in 150 ml of distilled water and heated to 65°C, then added colostrum, stirred with a magnetic stirrer for 30 minutes, and then ultrasonically treated with an ultrasonic cleaner for 60 minutes.

[0035] 4 Put the mixture obtained in step 3 in a separatory funnel and let it stand for 24 hours, take out the lower layer and freeze-dry it to obtain the desired NLC.

Embodiment 3

[0037] 1. Mix 0.5 grams of oil phase (containing 0.4 grams of peanut oil and 0.1 grams of stearic acid) with 1.0 grams of Span 80, heat to 65°C to become a molten liquid, and add 6.0 milligrams of retinoic acid to dissolve.

[0038] 2 Add the mixture obtained in step 1 into 150 ml of distilled water at 65°C, and simultaneously use a high-shear homogenizer to perform high-shear treatment to obtain colostrum.

[0039] 3 3.0 g of Tween 80 was dissolved in 50 ml of distilled water and heated to 65°C, then added colostrum, stirred with a magnetic stirrer for 20 minutes, and then ultrasonically treated with an ultrasonic cleaner for 40 minutes.

[0040] 4 Put the mixed solution obtained in step 3 in a separatory funnel and let it stand for 18 hours, take out the subnatant and freeze-dry it to obtain the desired NLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com