Catalyst component for ethene polymerization, preparing method and catalyst thereof

A technology for ethylene polymerization and catalysts, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. Static electricity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

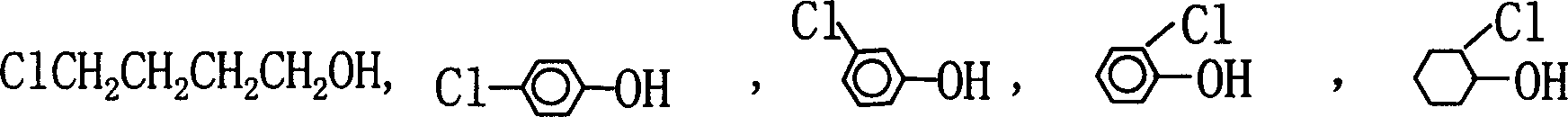

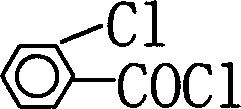

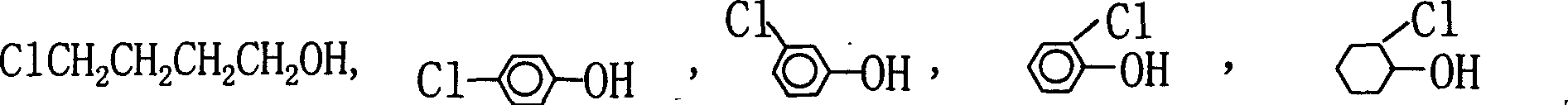

Method used

Image

Examples

Embodiment 1

[0034] (1) Take about 12 grams of spherical silica gel (model 948, Grace Company, USA) and activate it at 600° C. for 4 hours under the protection of nitrogen.

[0035] (2) Under the protection of nitrogen, in the reaction flask after high-temperature drying with a stirrer, add 5.0 grams of thermally activated silica gel obtained in step (1), 100 milliliters of purified hexane and 2.0 milliliters of Al(n-C 6 h 13 ) 3 hexane solution (1.5mmol / ml), react at 60°C for half an hour, add 0.6ml of silicon tetrachloride dropwise, and continue stirring for half an hour.

[0036] (3) Add 1.9ml Cl dropwise to the reactor at 60°C 3 CCH 2 OH, after constant temperature stirring for 1 hour, 10.0ml of 10.0ml of dibutylmagnesium in heptane solution (1M) was added dropwise, and after stirring for 2 hours, 0.6ml of titanium tetrachloride was added dropwise, and the reaction was continued at 60°C for 1 hour.

[0037] (4) The temperature of the reaction system was raised to 70° C., and then p...

Embodiment 2

[0043] Remove 2.0 milliliters of Al(n-C in catalyst preparation step (2) 6 h 13 ) 3 hexane solution (1.5mmol / ml), adjusted to 3.0ml Al(C 2 h 5 ) 3 Except the hexane solution (1.0mmol / ml), other conditions are the same as embodiment 1.

[0044] The evaluation conditions for the slurry polymerization of the catalyst are the same as in Example 1, and the polymerization results are shown in Table 1.

[0045] The electrostatic size of the catalyst solid powder was measured by the method described, and the results are shown in Table 1.

Embodiment 3

[0047] Except that the silicon tetrachloride in the catalyst preparation step (2) was adjusted to titanium tetrachloride, other conditions were the same as in Example 1.

[0048] The evaluation conditions for the slurry polymerization of the catalyst are the same as in Example 1, and the polymerization results are shown in Table 1.

[0049] The electrostatic size of the catalyst solid powder was measured by the method described, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com