Charcoal circulation type co-coagulation flotation tank water purification system and method

A technology of copolymerization air flotation and water purification system, which is applied in biological water/sewage treatment, chemical instruments and methods, flotation water/sewage treatment, etc. Effects of water loss, enhanced removal capacity, and effective speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

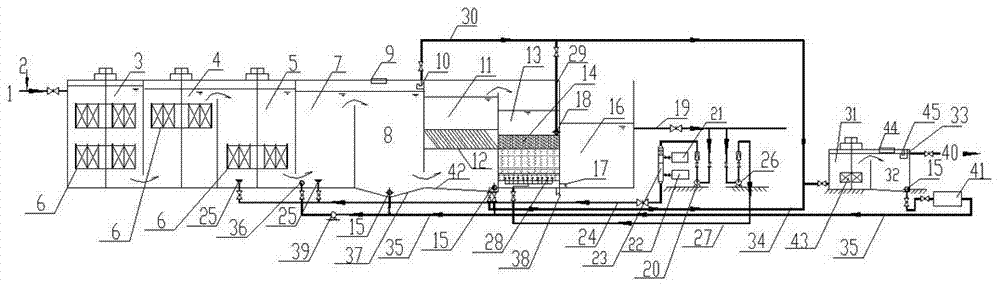

[0055] A biochar circulation type copolymerization air flotation tank water purification system is an integrated structure, including three-stage mechanical stirring copolymerization flocculation tank, ozone-biological activated carbon contact tank, bubble floc separation area, inclined plate sedimentation tank, sand filter, etc. Pool 13 and clear water pool 16, and ozonated dissolved air flotation device and release device, backwash device, powdered biological activated carbon recovery device and circulation system;

[0056] The three-stage mechanical stirring copolymerization flocculation tank, ozone-biological activated carbon contact tank, foam and floc separation zone, inclined plate sedimentation tank, sand filter tank, and clear water tank are connected horizontally in sequence, and the internal water flow is controlled through the tank walls between adjacent tank bodies; The ozonation dissolved air flotation device and release device are installed in parallel outside th...

Embodiment 2

[0067] A kind of method that adopts embodiment 1 biochar circulation type copolymerized air flotation tank water purification system to process common reservoir water, specifically comprises the following steps:

[0068] 1) The raw water enters the three-stage mechanical agitation copolymerization flocculation tank from the upper end of the coagulation 1 chamber 3 through the water inlet pipe 1, and at the same time, the coagulant is added with the raw water through the dosing pipe 2, and the water flows through the three coagulation chambers of the copolymerization mechanical flocculation tank in turn. , fully coagulate under the action of the mechanical shaft 6, and pass through the pool wall between the coagulation chambers to prevent the short flow of incoming water and ensure that the raw water and the coagulant are fully mixed. 3. Ozone-dissolved air water is released in room 5, and the water flow is ozonated while forming micro-nano bubbles, which plays a role in coagula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com