Dual core metallocene catalyst and preparation method and applications thereof

A metallocene compound and reaction technology, applied in the field of binuclear metallocene catalyst and its preparation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

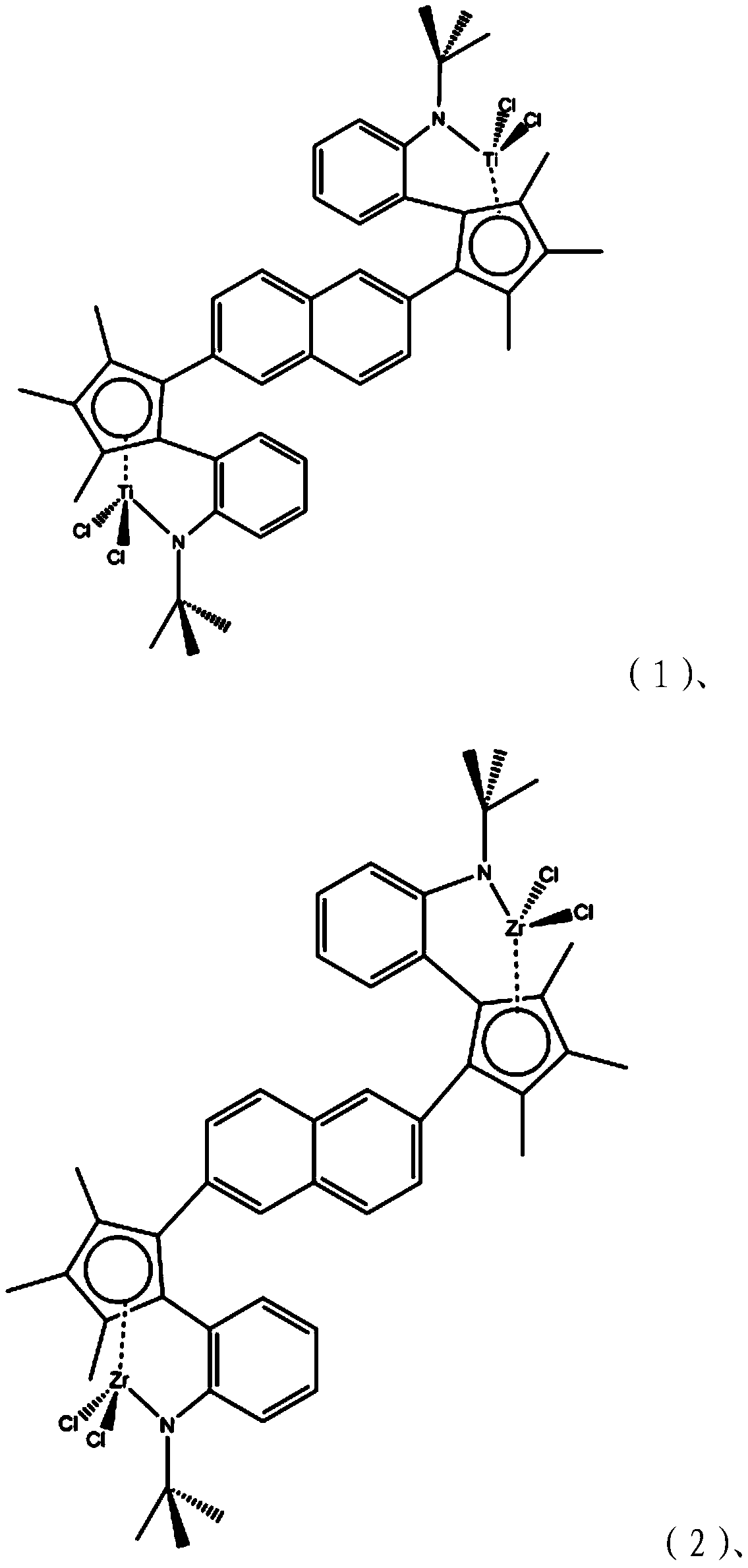

[0078] {[(Me 3 Cp)PhN t Bu]TiCl 2} 2 C 10 h 6 The preparation method route of catalyst is as follows:

[0079]

[0080] 1) Preparation of component 1

[0081] Add 2,6-dibromonaphthalene (14.298g, 50mmol) into 50mL diethyl ether solvent, stir slowly at -50°C and add 40mL 2.5M n-BuLi hexane solution dropwise, and rise to room temperature ( 25°C or so) stirring and reacting for 6h, the obtained white turbid suspension was filtered to obtain a white solid lithium salt;

[0082] The resulting product was added to 40 mL of THF solvent, cooled to -78°C, and a mixed solution of 2,3,4-trimethylcyclopent-2-enone (12.433 g, 100 mmol) and 20 mL of THF was slowly added dropwise, After the dropwise addition, raise it to room temperature (about 25°C) and stir for 10 hours. After the reaction, filter the solid and remove the solvent to obtain a colorless oily liquid; A small amount of formic acid (0.046 g, 1 mmol) was added, stirred for 1 h, then 60 mL of n-hexane was added, stirre...

Embodiment 2

[0091] {[(Me 3 Cp)SiMe 2 N t Bu]TiCl 2} 2 C 10 h 6 The preparation method route of catalyst is as follows:

[0092]

[0093] 1) Preparation of component 1

[0094] Add 2,6-dibromonaphthalene (14.298g, 50mmol) into 50mL diethyl ether solvent, stir slowly at -50°C and add 40mL 2.5M n-BuLi hexane solution dropwise, and rise to 25°C after the dropwise addition Stir left and right to react for 6 hours, and filter the obtained white turbid suspension to obtain a white solid lithium salt; add 40mL THF solvent, cool to -78°C, slowly add 2,3,4-trimethylcyclopentyl- Mixed solution of 2-enone (12.433g, 100mmol) and 20mL of THF. After the dropwise addition, raise the temperature to about 25°C and stir for 10h. After the reaction, filter the solid and remove the solvent to obtain a colorless oily liquid. Continue to add 40mL Added p-toluenesulfonic acid (0.172g, 1mmol) at room temperature (around 25°C), stirred for 1 hour, added 60 mL of n-hexane, stirred and washed for 0.5 hour...

Embodiment 3

[0104] Ethylene / α-olefin solution copolymerization was carried out in a 2L stainless steel batch reactor with magnetic stirring.

[0105] Under the protection of inert gas, add 1000mL Isopar E solvent and 5mL 1.1M triisobutylaluminum hexane solution to the reaction kettle, stir quickly to remove the water and oxygen impurities in the reaction kettle, then dry it under high temperature vacuum and replace it with ethylene gas three times. Keeping the slight positive pressure in the kettle, add 1000mL of Isopar E solvent, 250mL of 1-octene and 6.7mL of 1.5M MAO hexane solution to the reaction kettle in sequence at a stirring speed of 500rpm, then raise the temperature to the reaction temperature of 90°C, and pass Enter ethylene gas to keep the pressure in the kettle stable at the required polymerization reaction pressure of 1.0Mpa; then add 5mL of 0.002M Isopar E solution of component 3 (prepared in Example 1) to the kettle by ethylene pressure to start polymerization reaction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com