Method for closing used hole on top of gas turbine blade

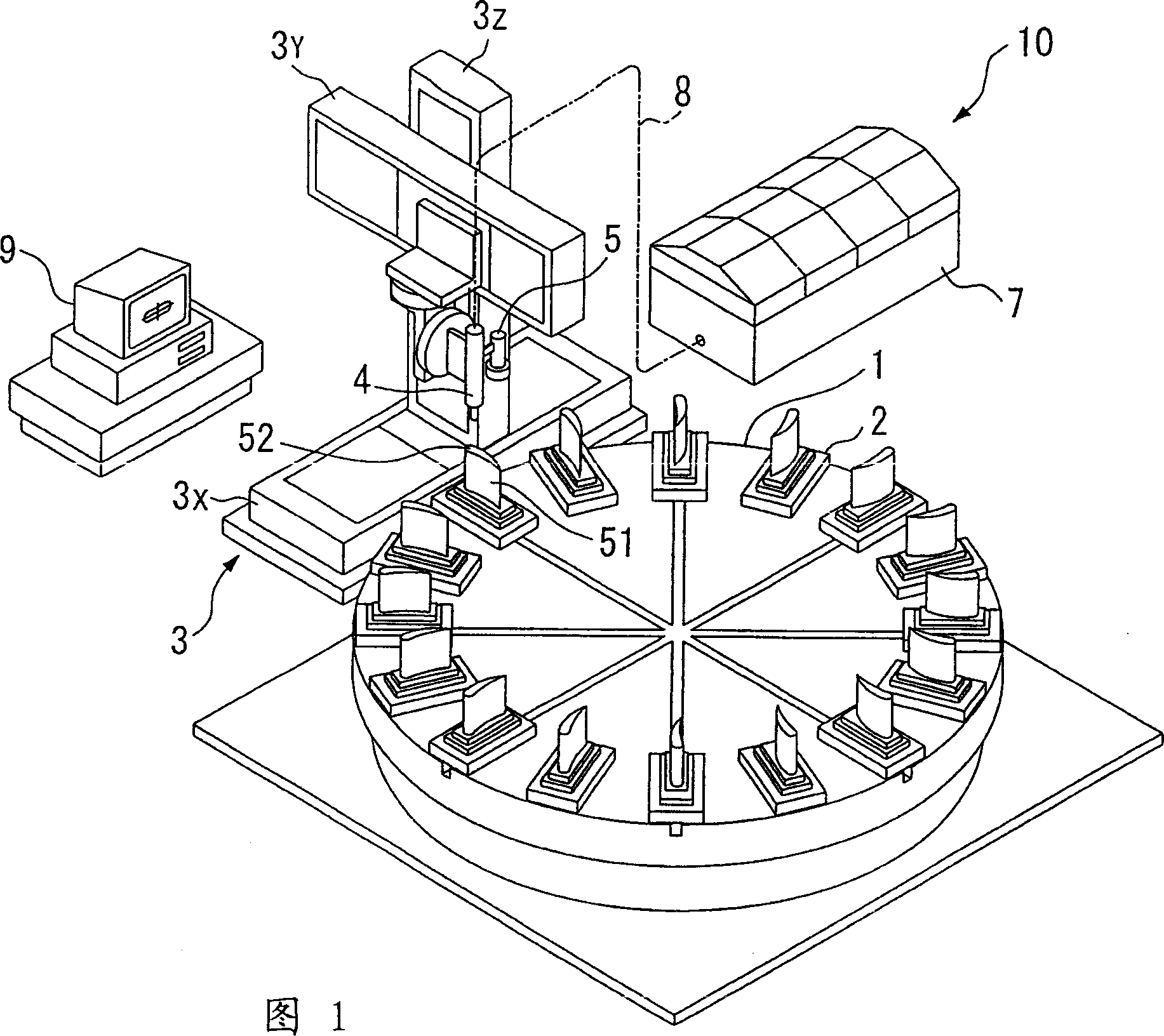

A technology of gas turbine and blade tip, which is applied in the field of plugging the hole on the gas turbine blade tip and blocking the hole on the gas turbine blade tip, which can solve the problems of melting depth change, cracks in the welded part, uncontrollable plug and bottom plate parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

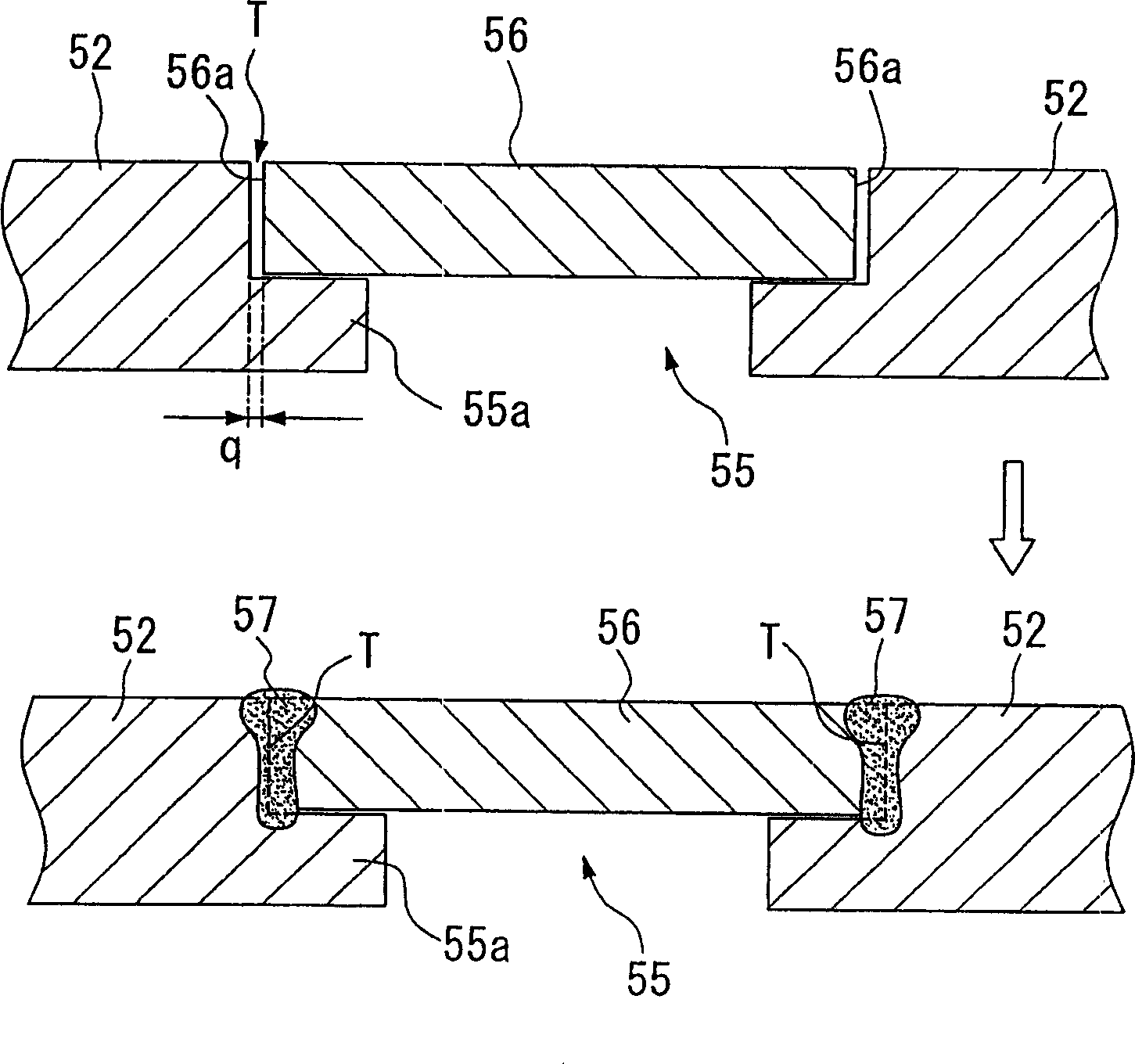

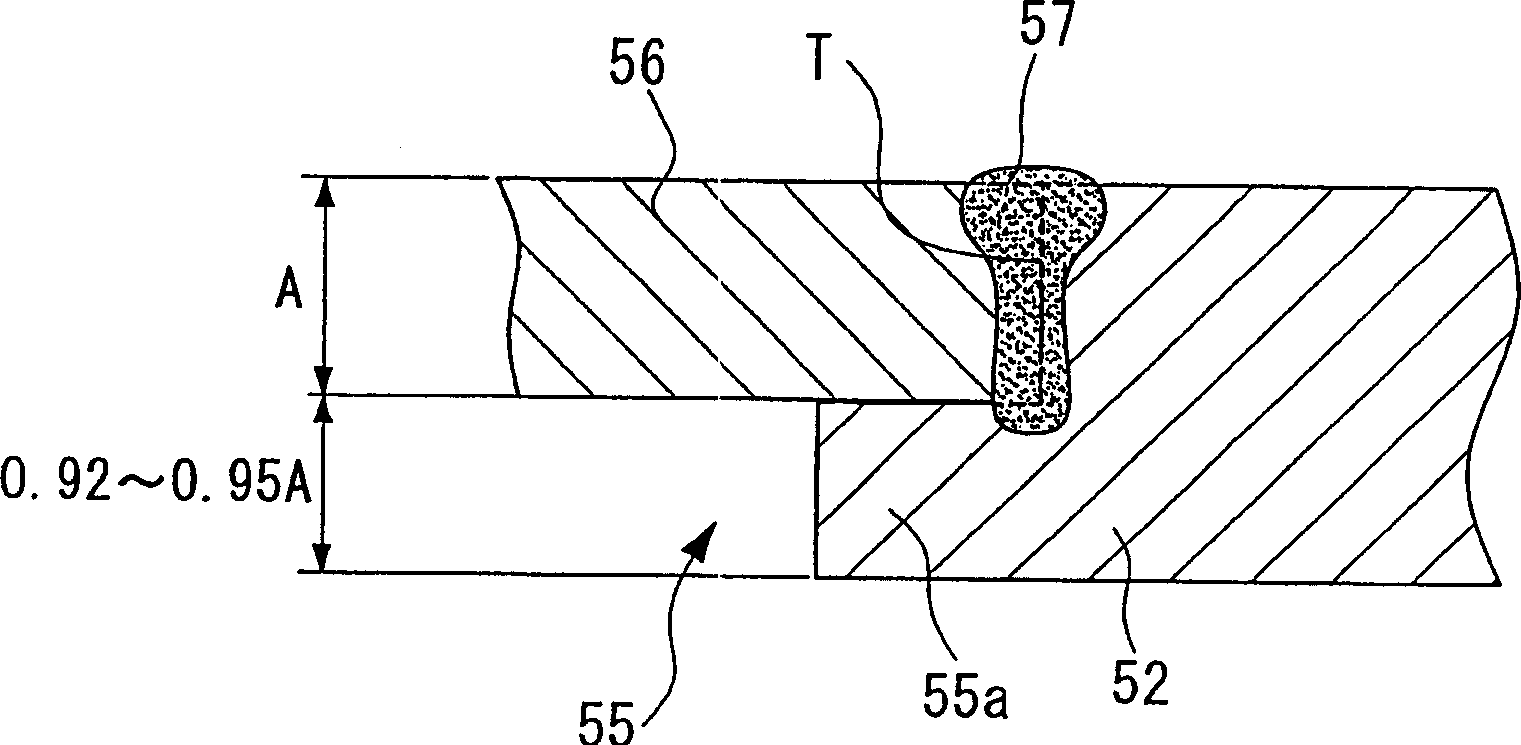

[0074] In an embodiment of the invention, the hole 55 in the tip portion 52 of the turbine blade body 51 formed from the MGA1400DS component is passed through as Figure 7A and 7B The manner shown performs a YAG laser butt welding operation and is plugged by a tip plug 56 made of Inconel 625, a nickel-based superalloy. Should

[0075] The parameters in the examples are as follows.

[0076] (Specification of blade tip part 52)

[0077] Components used to form the tip portion 52: MGA1400DS

[0078] The shape of hole 55: oval

[0079] (parameters of blade tip plug 56)

[0080] Components used to form the tip plug 56: Nickel-based superalloy Inconel 625

[0081] The shape of the blade tip plug 56: oval plate

[0082] A tip plug 56 made according to the above specification is placed on the protruding boss portion 55a of the bore 55 and Figure 7A (plan view) and 7B (side view) were mounted to holes 55 for testing fatigue strength. Also, the laser butt welding operation was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com