Control box device for sewing mechine

A sewing machine and control box technology, applied in the direction of sewing machine control devices, sewing machine components, sewing machine housings, etc., can solve problems such as frame P26 deformation, and achieve the effects of avoiding negative effects, improving cooling effect, and reliable ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

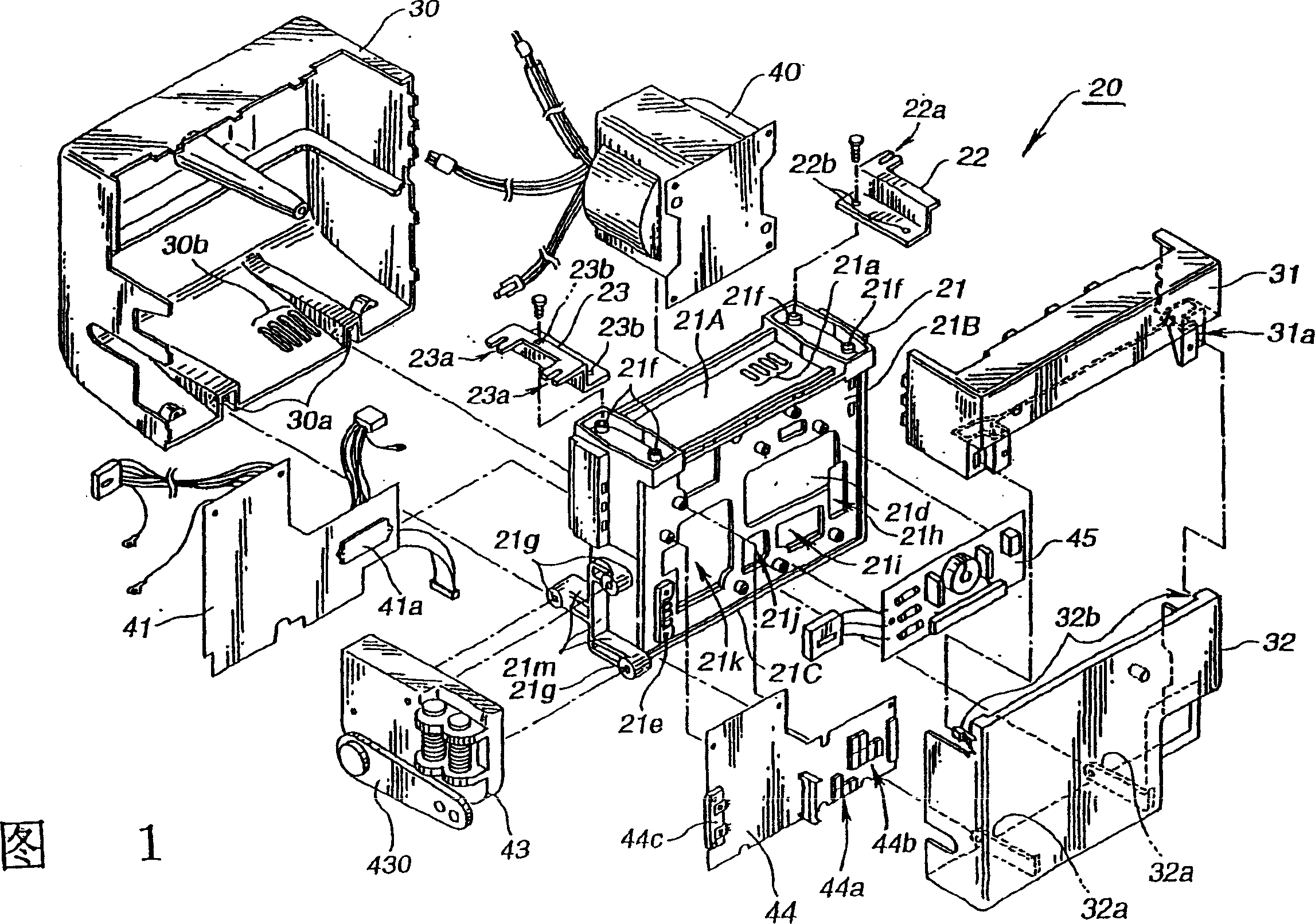

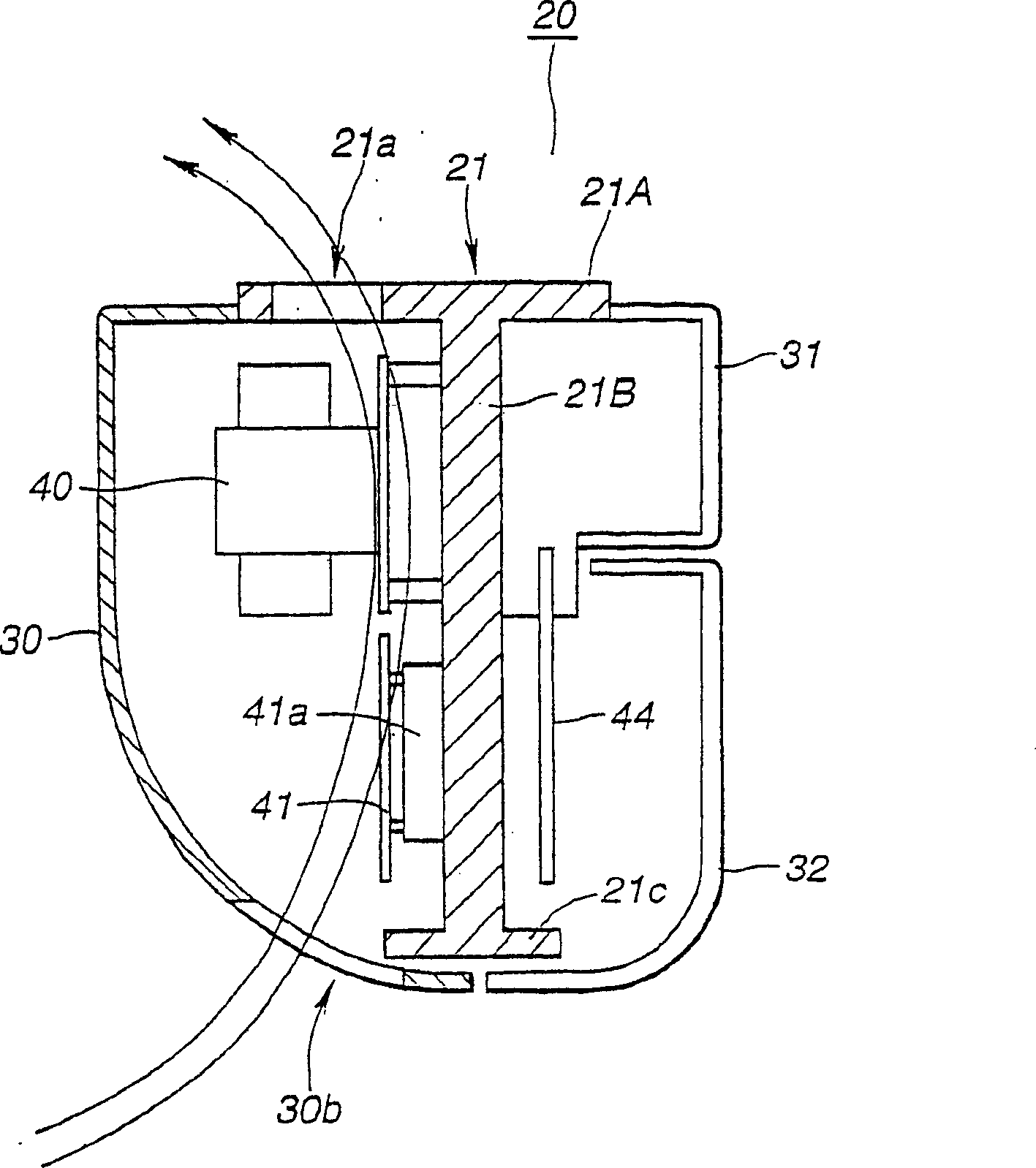

[0054] The control box 20 of this embodiment is composed of a frame 21 as a main frame on which several electrical components are installed; a first cover 30 covering the outside, a second cover 31 and a third cover 32, and mounting accessories 22 and 23 as mounting components. .

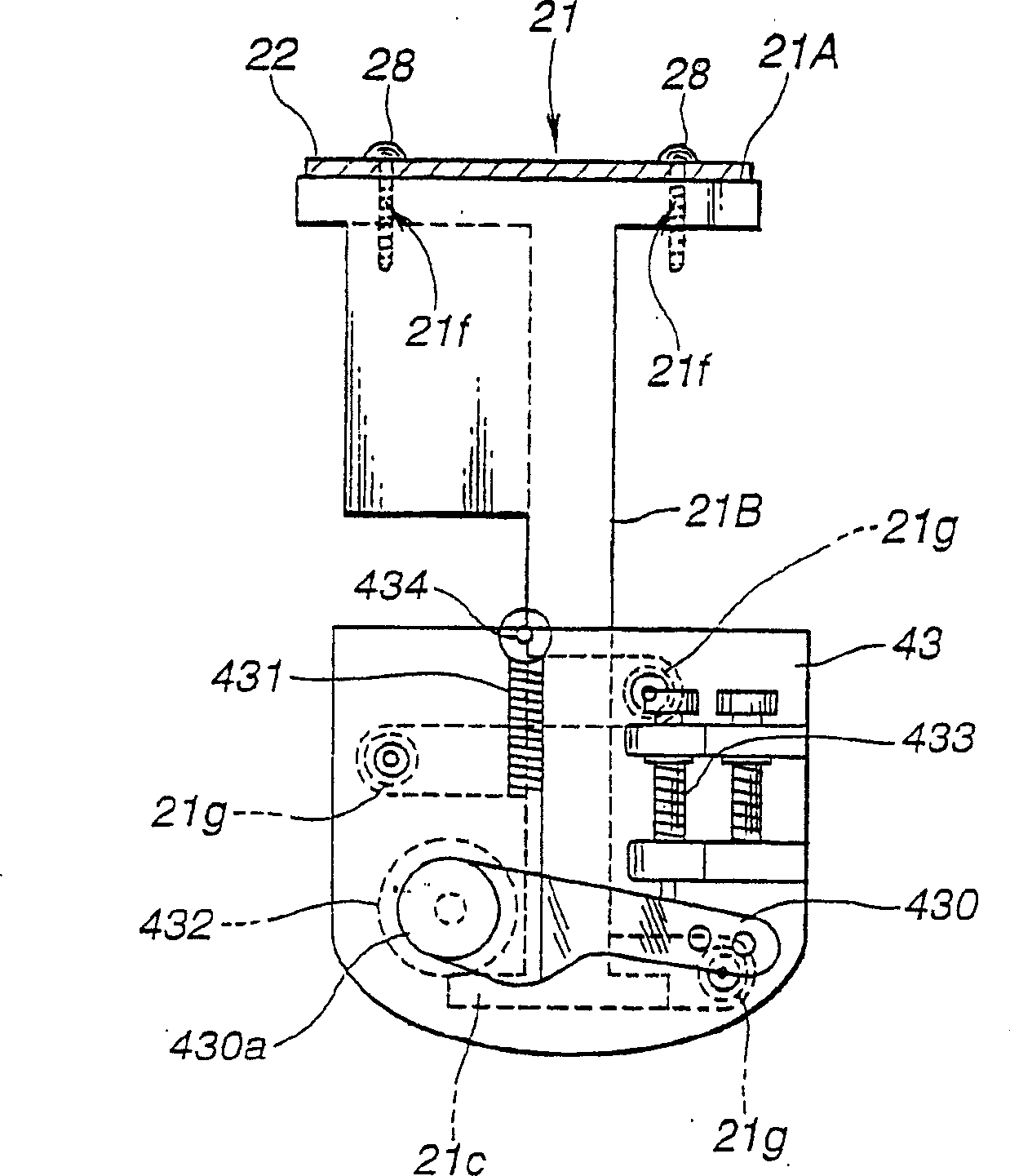

[0055] The frame 21 is made of metal, such as integrally formed with aluminum die-casting parts, and made as figure 2 The section shown is T-shaped, and consists of a plate-shaped main frame part (frame member) 21B extending in the vertical direction, an upper frame part 21A and a lower frame part 21C arranged horizontally above and below the main frame part 21B, etc. constitute. The upper frame part 21A is not only used as a reinforcing member because of the high bending stress of the main frame part 21B, but also serves as a base frame for installing the control box 20 at the installation position, and forms an installation fitting for fixing the control box 20 for installation. 22, 23 screw ho...

no. 2 Embodiment

[0082] Figure 8 The sewing machine control box 200 of the second embodiment is shown.

[0083] In the control box 200 of this embodiment, the frame portion 153 and the lower cover portion 150 are integrally formed, and other configurations are basically the same as those of the first embodiment.

[0084] The frame body 152 is made into a Y-shaped section structure, and the upper end 150D of the lower cover portion 150 of the upper structure hangs around the sewing machine installation hole 102A of the sewing machine table 102 to support it. Furthermore, there is provided a frame portion 153 hanging downward from the center portion in the front-rear direction of the lower end surface (constituting the upper frame portion) 150B of the lower cover portion 150 .

[0085] The first cover 160 covering the rear of the frame portion 153, the second cover 161 covering the front and upper side of the frame portion 153, and the third cover 162 covering the front of the frame portion 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com