Static charge developing agent and imaging method

An imaging method and developer technology, applied in the direction of developer, electric recording process using charge pattern, equipment for electric recording process using charge pattern, etc., to achieve stable and good copying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

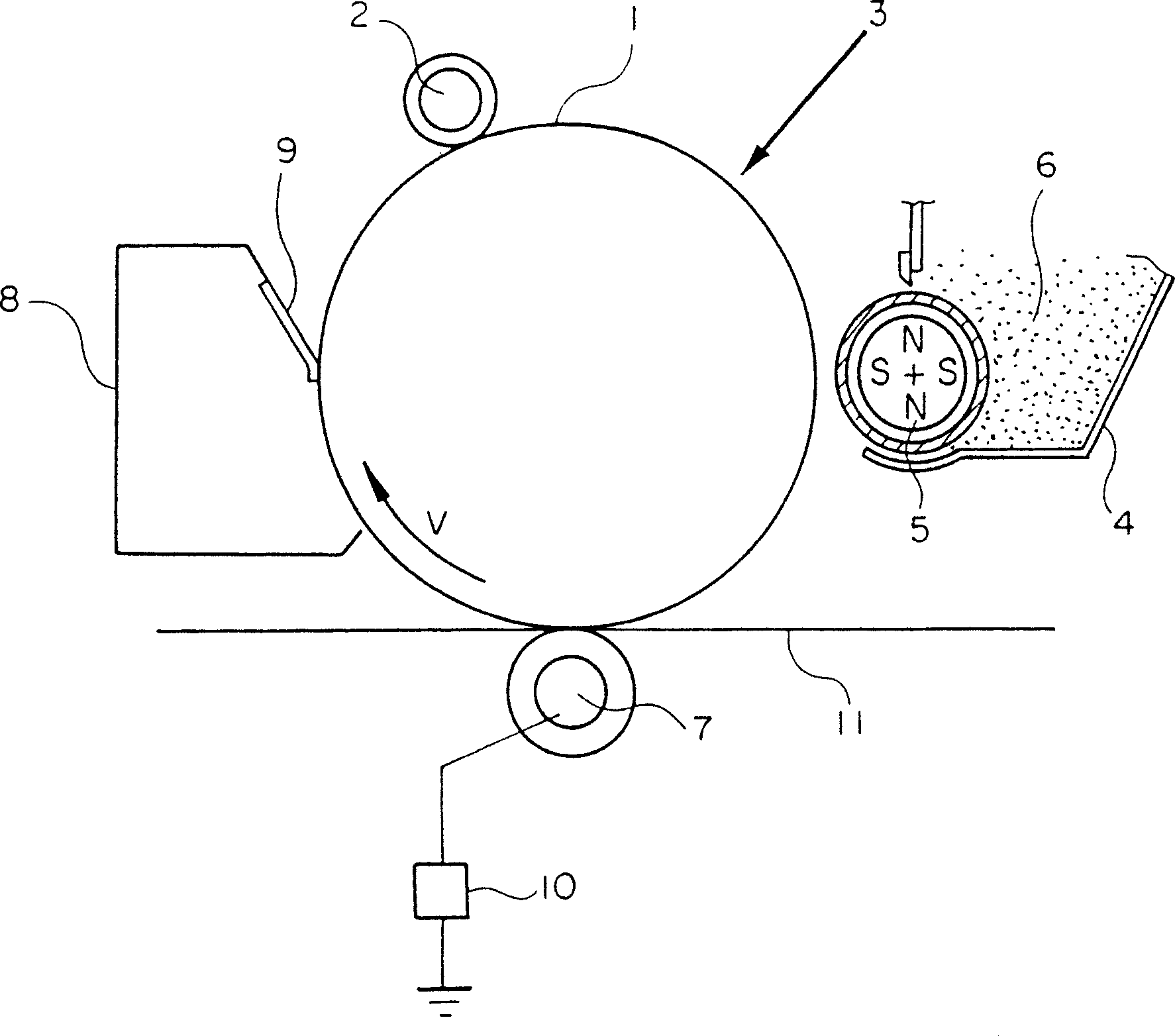

Method used

Image

Examples

Embodiment

[0075] The present invention is described in more detail below by way of examples, but the following examples do not constitute any limitation to the present invention. In addition, in the following, "parts" all represent "parts by weight".

[0076] First, the method for producing the silicon carbide fine powder used in the first embodiment will be specifically described. The silicon carbide fine powders adopted in the 2nd to 6th embodiments and the 1st to 2nd comparative examples can be adjusted to the amount of the coagulant added, or measures such as the primary particle size of the fine particles to be compared with the following Manufactured in the same way.

[0077] (Manufacture of silicon carbide fine powder)

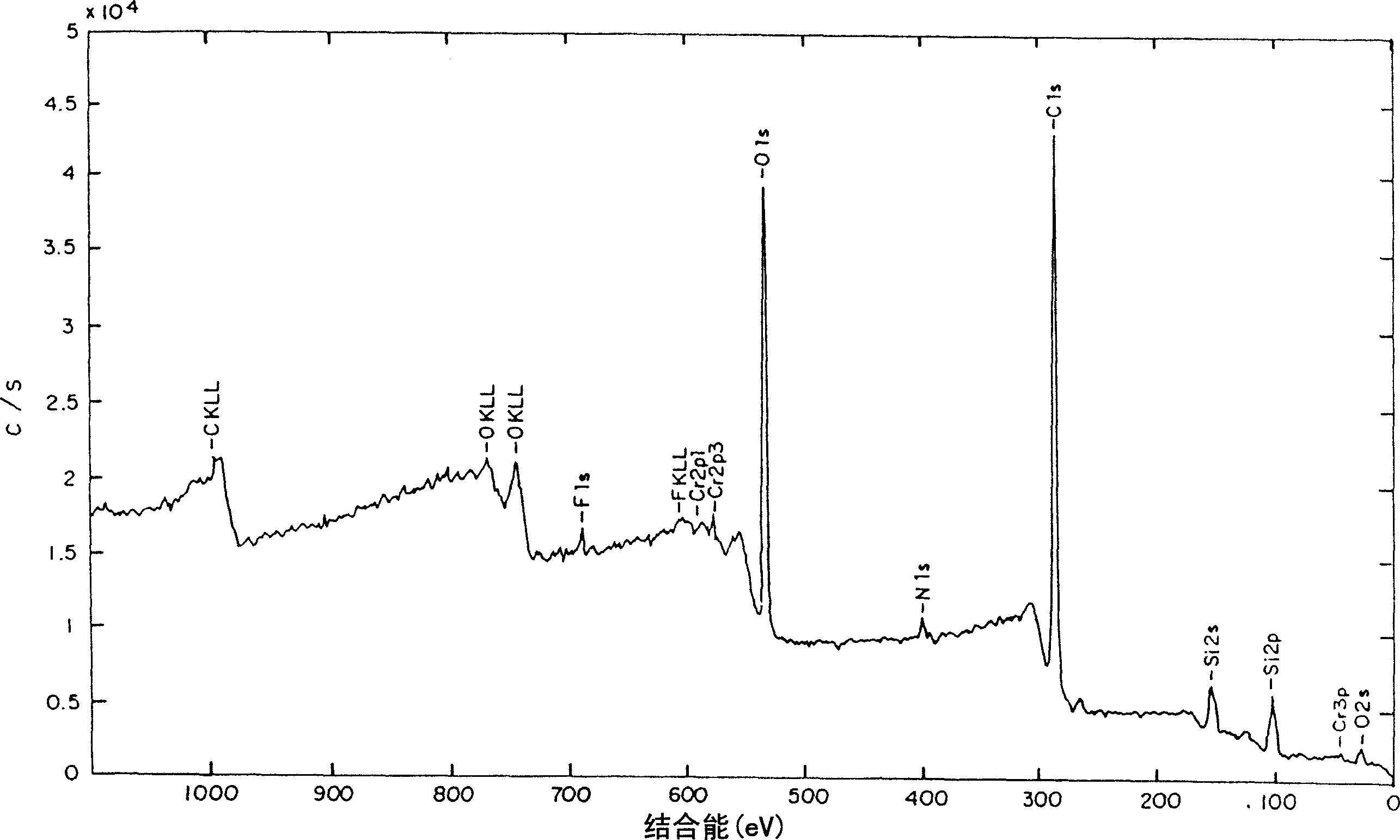

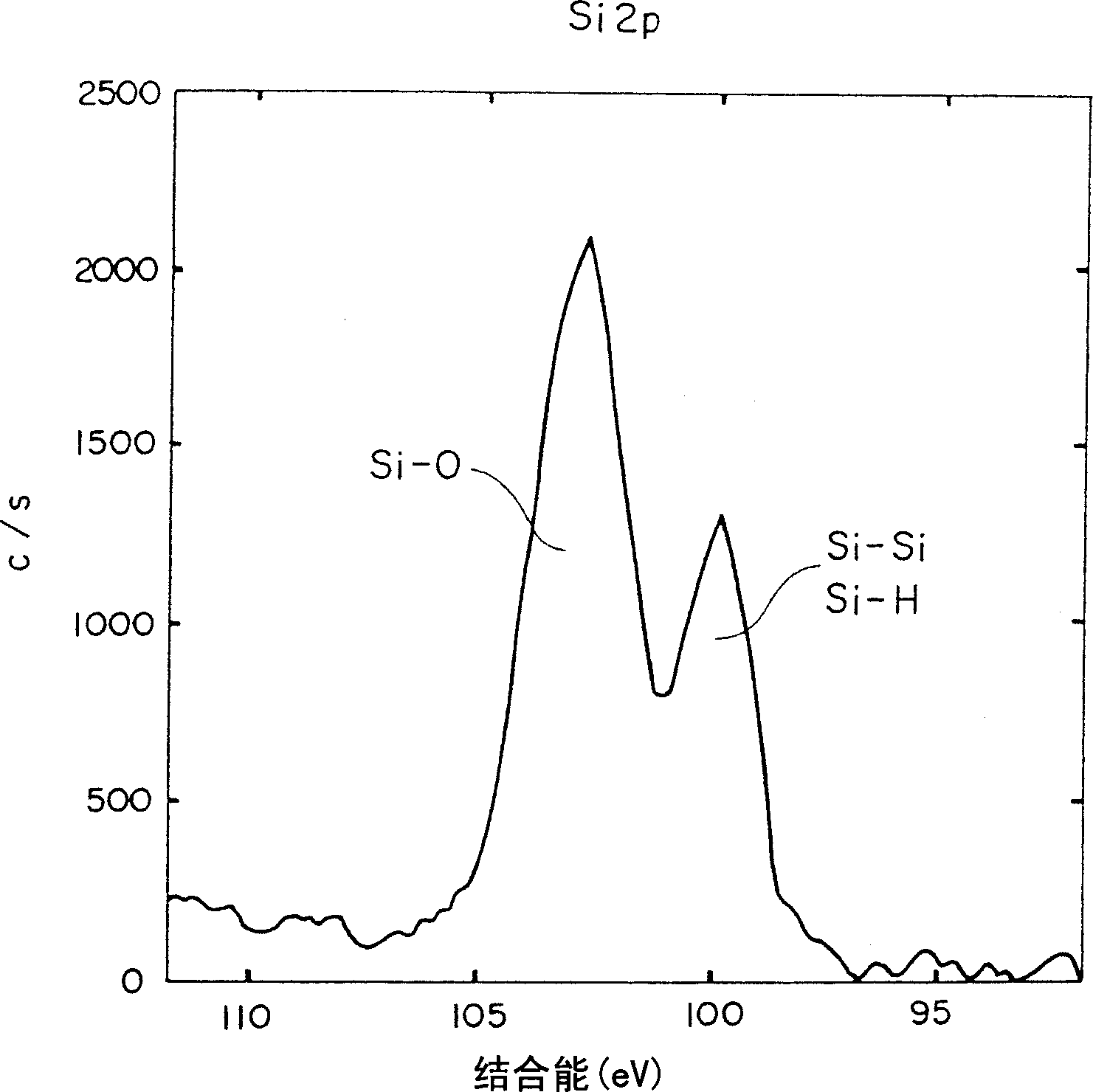

[0078] After being synthesized by the Acheson method, D 50 (average particle size) = 25μm, S.A. (specific surface area) = 0.07m 2 Raw materials for pulverization of α-SiC / g (BET method. The same below) are put into a pulverizer with water and iron pellets to c...

no. 1 Embodiment

[0099] Manufacture of developer

[0100] 100 parts of copolymer of styrene and acrylate

[0101] Magnetic body (magnetite) 93 parts

[0102] Nigrosine dye 6 parts

[0103] 3 parts synthetic paraffin

[0104] The above-mentioned components were uniformly mixed, then stirred, pulverized, and classified to obtain positively charged toner particles with an average particle diameter of 10.4 μm. Next, to 100 parts of the toner particles, 0.3 parts of silica fine powder treated with dichlorodimethylsilane, and 0.42 μm in average primary particle size and 26.3 μm in specific surface area were added. 2 / g, 40.6% of solidified particles, 0.21% by weight of Fe element attachment, and 0.25% by weight of Al element attachment were mixed with 1.0 parts of silicon carbide fine powder to obtain a positively charged magnetic toner.

[0105] copy test

[0106] Using the toner obtained in the above manner, in a commercially available digital copier GP-605 (manufactured by Canon Corporati...

no. 2 Embodiment

[0113] Manufacture of developer

[0114] With respect to 100 parts of toner particles produced in the first example, 0.4 parts of silica fine powder treated with dichlorodimethylsilane was added, and the average primary particle diameter was 0.32 μm, and the specific surface area was 31.6 μm. 2 / g, 52.7% of solidified particles, 0.30% by weight of Fe element attachment, and 0.437% by weight of Al element attachment, 1.0 parts of silicon carbide fine powder were mixed to obtain a positively charged magnetic toner.

[0115] copy test

[0116] Using the toner obtained in the above manner, in the commercially available digital duplicating machine iR8500 (manufactured by Canon Corporation), the Si—O on the drum surface is loaded with an amorphous silicon photosensitive drum (A) of 67.5%, at normal temperature and normal temperature. In wet (23°C, 50%RH), high temperature and normal humidity (30°C, 85%RH), low temperature and low humidity (10°C, 20%RH) environments, a real prin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com