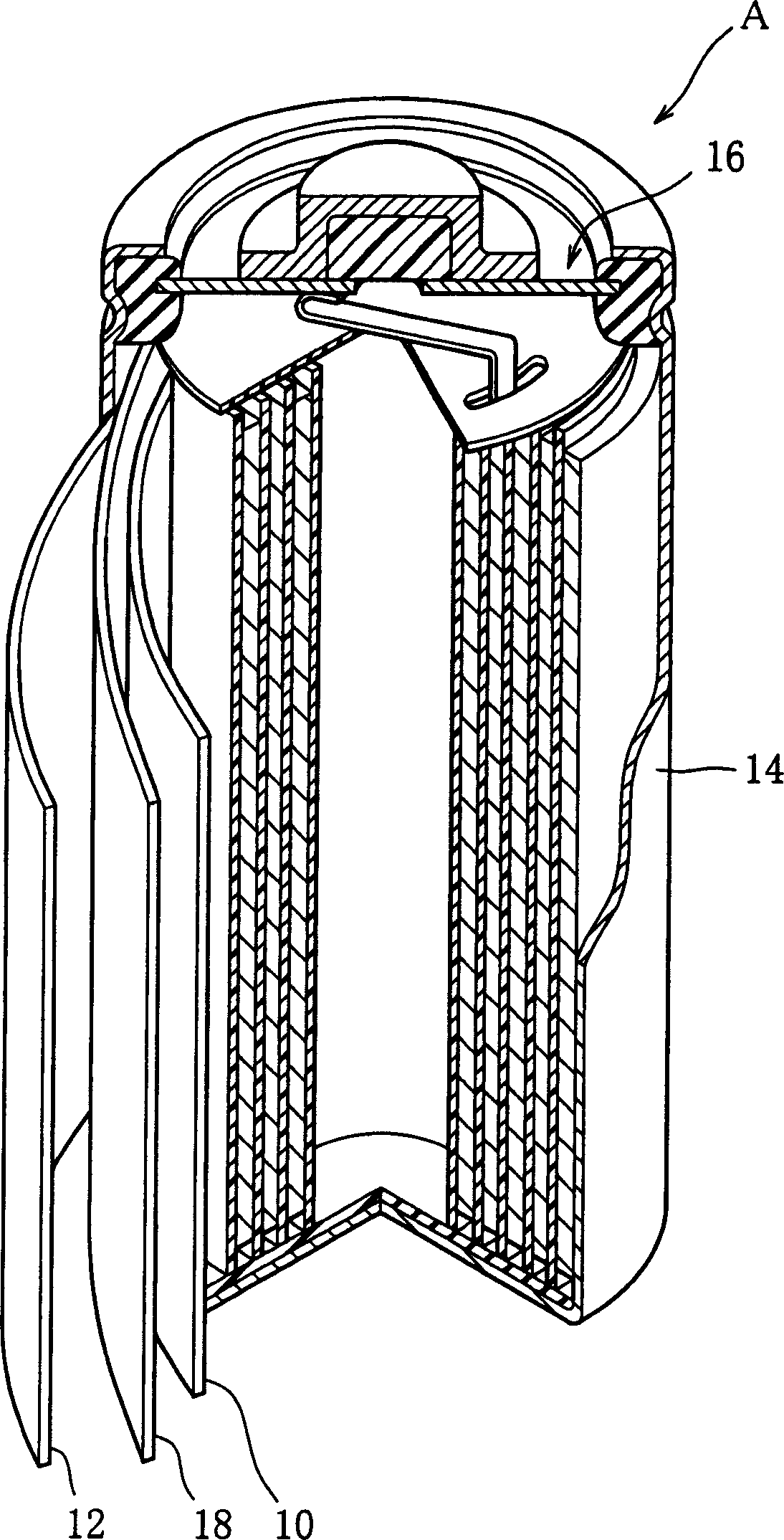

Nickel hydrogen secondary battery

A secondary battery, nickel metal hydride technology, applied in the direction of secondary batteries, nickel storage batteries, battery electrodes, etc., can solve the problem of battery capacity reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. Fabrication of positive electrode

[0055] A mixed aqueous solution of nickel sulfate, zinc sulfate, and cobalt sulfate was prepared at a ratio of 3% by mass of Zn and 1% by mass of Co in terms of amounts relative to Ni. To this mixed aqueous solution, an aqueous sodium hydroxide solution was slowly added with stirring and allowed to react. At this time, the pH of the mixed aqueous solution during the reaction was maintained at 13 to 14, and approximately spherical nickel hydroxide particles were precipitated in the mixed aqueous solution. Then, the nickel hydroxide particles were washed three times with 10 times the amount of pure water, and then dehydrated and dried to obtain a powder of nickel hydroxide particles.

[0056] Then, this powder, equivalent to 5% by mass of diyttrium trioxide (Y 2 o 3 ) powder, the HPC (hydroxypropyl cellulose) dispersion liquid (dispersant: water 40 mass parts, solid content 60 mass parts) that are equivalent to 40 mass % mix, make...

Embodiment 2~11

[0066] When making the positive electrode, replace Y 2 o 3 powder, adding equivalent to 5% by mass of Nb 2 o 5 , Yb 2 o 3 、Er 2 o 3 , Ca(OH) 2 , SrO, Ba(OH) 2 、TiO 2 、WO 3 、MoO 3 or Ta 2 o 5 For the formed powder, an AA-size nickel-hydrogen secondary battery having a nominal capacity of 1200 mAh was produced in the same manner as in Example 1 except that the value of x in the hydrogen storage alloy was changed as shown in Table 1.

Embodiment 12

[0068] When making the positive electrode, except that instead of the powder formed by nickel hydroxide particles, the powder of composite particles in which the surface of the nickel hydroxide particles is covered by a coating layer formed by cobalt hydroxide is used, the others are the same as in Example 1, and a AA size nickel metal hydride secondary battery with a nominal capacity of 1200mAh.

[0069] That is, when producing a positive electrode, nickel hydroxide particles are precipitated in a mixed aqueous solution, and then an aqueous cobalt sulfate solution is added thereto and allowed to react. Here, the pH of the mixed aqueous solution during the reaction was kept at 9 to 10, and cobalt hydroxide was deposited on the surface of the previously deposited approximately spherical nickel hydroxide particles. Then, the approximately spherical nickel hydroxide particles whose surface is covered with cobalt hydroxide are washed 3 times with 10 times the amount of pure water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com