a surface coating li 2 tio 3 Lithium cobaltate-based composite cathode material and preparation method thereof

A composite positive electrode material and surface coating technology, applied in the field of lithium cobalt oxide-based composite positive electrode material and its preparation, can solve the problems of reducing the conductivity of lithium cobalt oxide, unstable material structure, affecting cycle performance, etc., and achieve electrochemical performance. Excellent, improve electrochemical performance, improve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

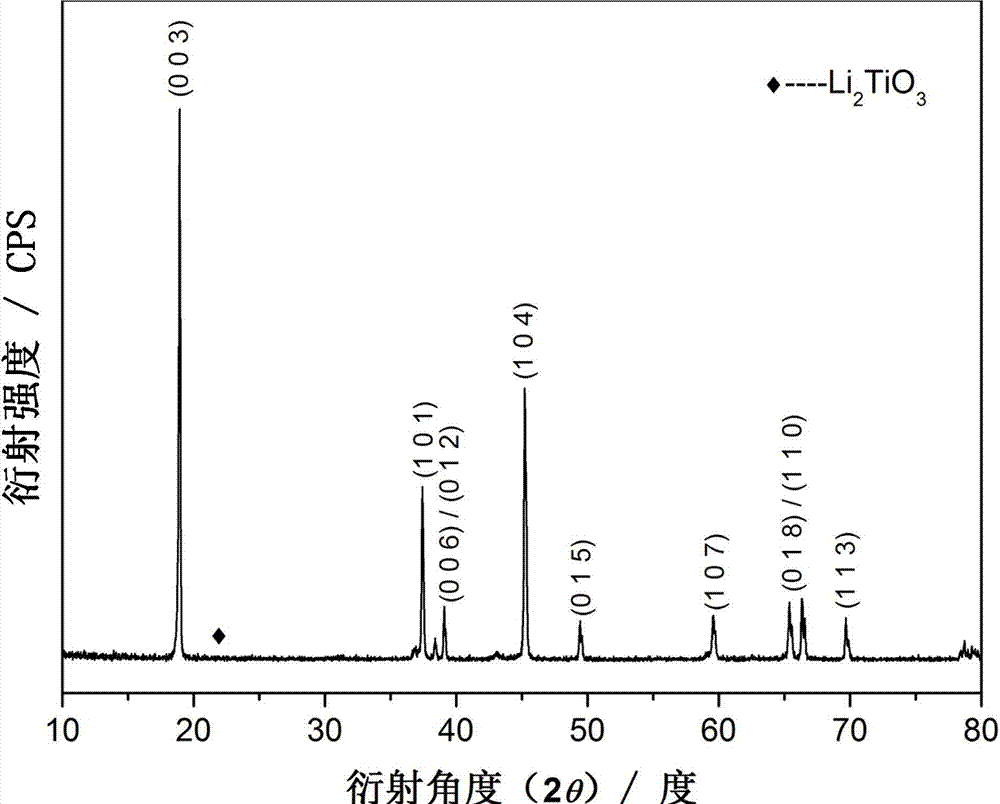

[0029] A kind of surface coating Li of the present invention2 TiO 3 Lithium cobaltate-based composite positive electrode material, with 0.03Li 2 TiO 3 0.97LiCoO 2 Titanium-containing lithium cobalt oxide-based composite material is used as the matrix, and the surface is coated with Li 2 TiO 3 , Li 2 TiO 3 The mass accounts for 0.5% of the mass of the positive electrode material.

[0030] The preparation method of the above-mentioned lithium cobaltate-based composite positive electrode material, the specific operation steps are:

[0031] 1) Take lithium acetate, cobalt acetate, and n-butyl titanate as raw materials, weigh and mix the raw materials according to the molar ratio of Li, Co, and Ti of 1.08:0.97:0.03, add deionized water and stir, and prepare a total metal concentration of 0.5mol / L solution; the solution was spray-dried to obtain 0.03Li 2 TiO 3 0.97LiCoO 2 Precursor: The precursor is pre-fired at 450°C for 4 hours in an air atmosphere, ground after cooling...

Embodiment 2

[0038] A kind of surface coating Li of the present invention 2 TiO 3 Lithium cobaltate-based composite positive electrode material, with 0.01Li 2 TiO 3 0.99LiCoO 2 Titanium-containing lithium cobalt oxide-based composite material is used as the matrix, and the surface is coated with Li 2 TiO 3 , Li 2 TiO 3 The mass accounts for 5% of the mass of the positive electrode material.

[0039] The preparation method of the above-mentioned lithium cobaltate-based composite positive electrode material, the specific operation steps are:

[0040] 1) Take lithium nitrate, cobalt nitrate, and titanium nitrate as raw materials, weigh and mix the raw materials according to the molar ratio of Li, Co, and Ti of 1.11:0.99:0.01, add deionized water and stir, and prepare a total metal concentration of 0.1mol / L solution; the solution was spray-dried to obtain 0.01Li 2 TiO 3 0.99LiCoO 2 Precursor: The precursor is pre-fired at 300°C for 1 hour in an air atmosphere, ground after cooling, ...

Embodiment 3

[0045] A kind of surface coating Li of the present invention 2 TiO 3 Lithium cobaltate-based composite positive electrode material, with 0.1Li 2 TiO 3 0.9LiCoO 2 Titanium-containing lithium cobalt oxide-based composite material is used as the matrix, and the surface is coated with Li 2 TiO 3 , Li 2 TiO 3 The mass accounts for 0.2% of the mass of the positive electrode material.

[0046] The preparation method of the above-mentioned lithium cobaltate-based composite positive electrode material, the specific operation steps are:

[0047] 1) Take Lithium Chloride, Cobalt Chloride, and Titanium Tetrachloride as raw materials, weigh and mix the raw materials according to the molar ratio of Li, Co, and Ti of 1.1:0.9:0.1, add deionized water and stir, and prepare a total metal concentration of 1mol / L solution; the solution was spray-dried to obtain 0.1Li 2 TiO 3 0.9LiCoO 2 Composite material precursor; the precursor is pre-fired at 500°C for 8 hours in an air atmosphere, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com