Built-in antenna and its manufacturing method and fixing method, and electronic apparatus asing same

A manufacturing method and technology of fixing method, applied in the directions of antenna support/installation device, antenna, resonant antenna, etc., can solve the problems of deterioration of antenna characteristics, problems in manufacturing efficiency, deterioration of antenna performance, etc., so as to reduce installation man-hours and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

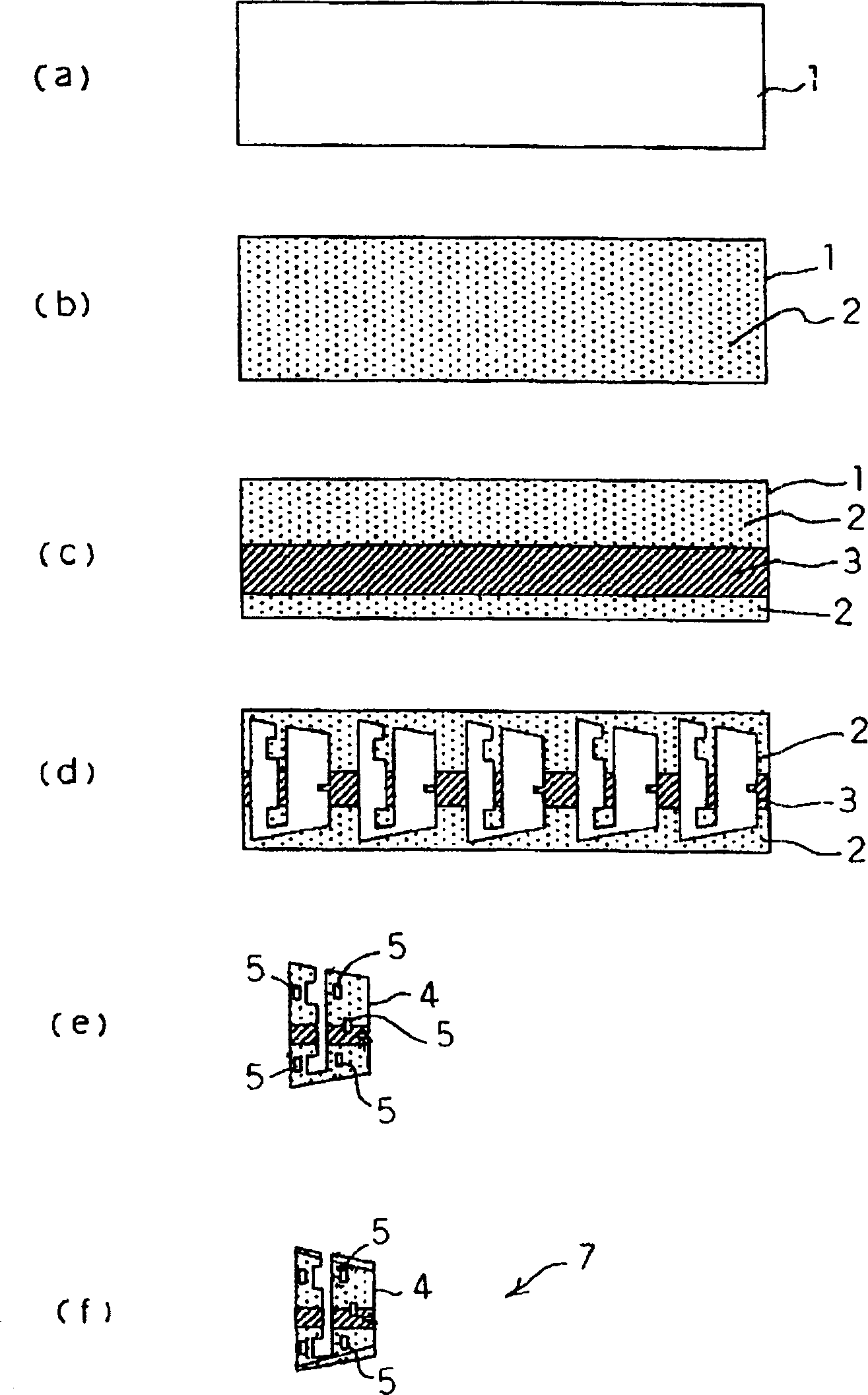

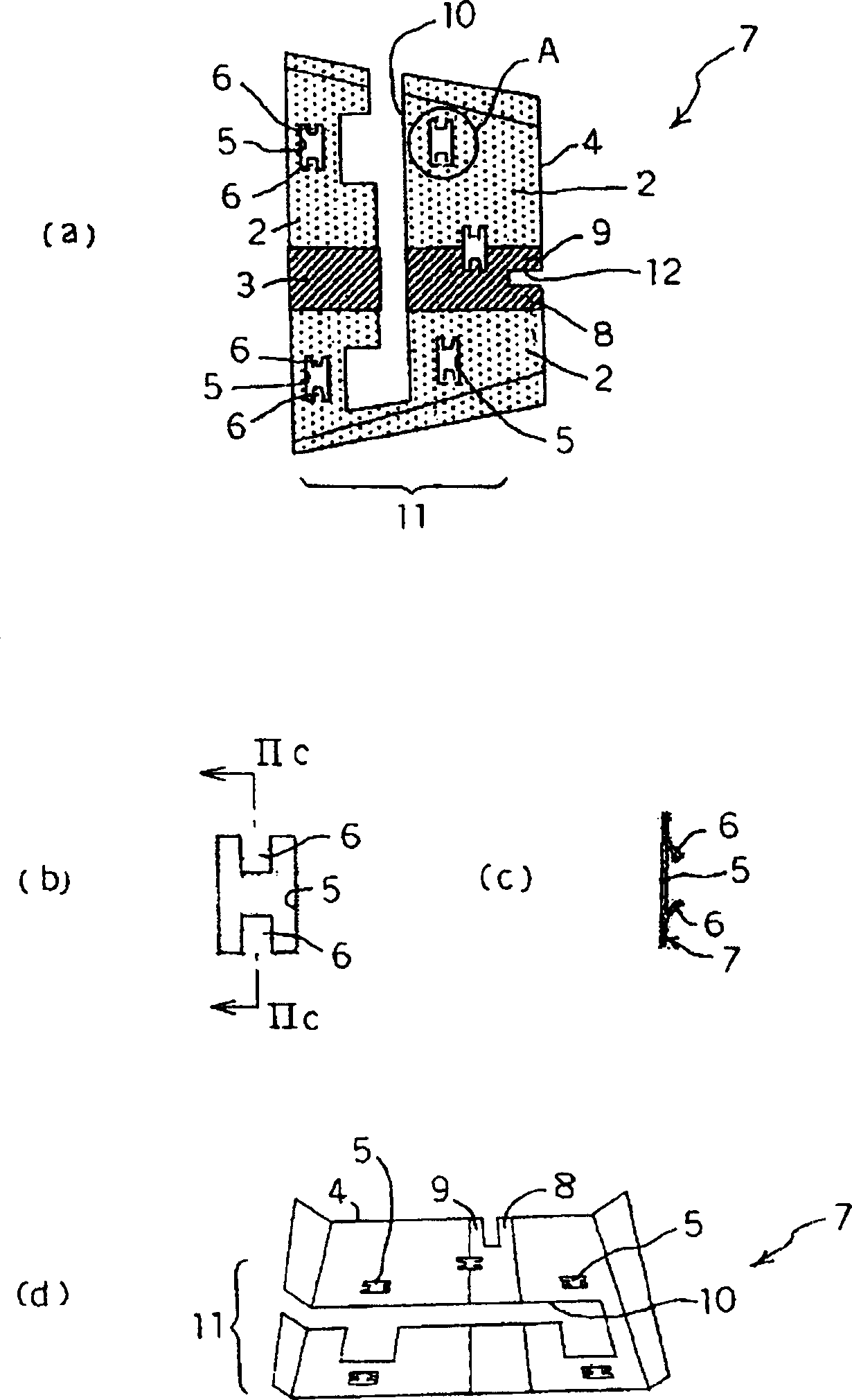

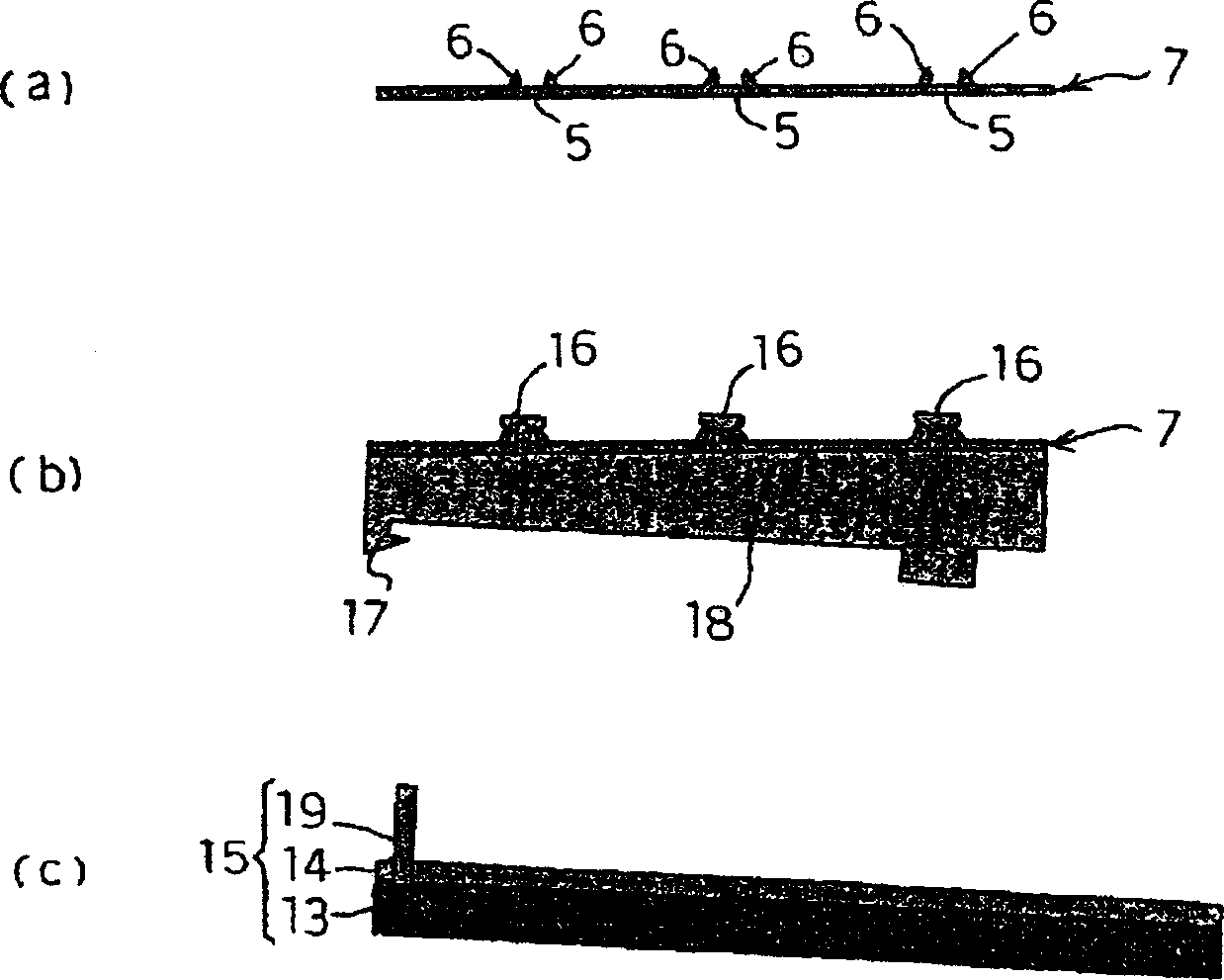

[0032] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

[0033] figure 1 (a) to (f) are process diagrams showing one embodiment of the method for manufacturing a built-in antenna according to the present invention.

[0034] First, if figure 1 Shown in (a), prepare rectangular metal plate (such as copper plate) 1, in order to prevent this metal plate 1 from being corroded, it is immersed in the Ni plating solution, and as figure 1 As shown in (b), the Ni plating layer 2 is formed on the entire surface of the metal plate 1 .

[0035] Next, on the surface of this Ni-plated layer 2, use masking tape (not shown) to stick to the area outside the bar-shaped area formed, it is immersed in the Au plating solution, such as figure 1 As shown in (c), the Au plating layer 3 for stabilizing the conductivity of the contact portion (the power supply terminal and the ground terminal described later) is formed on the stripe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com