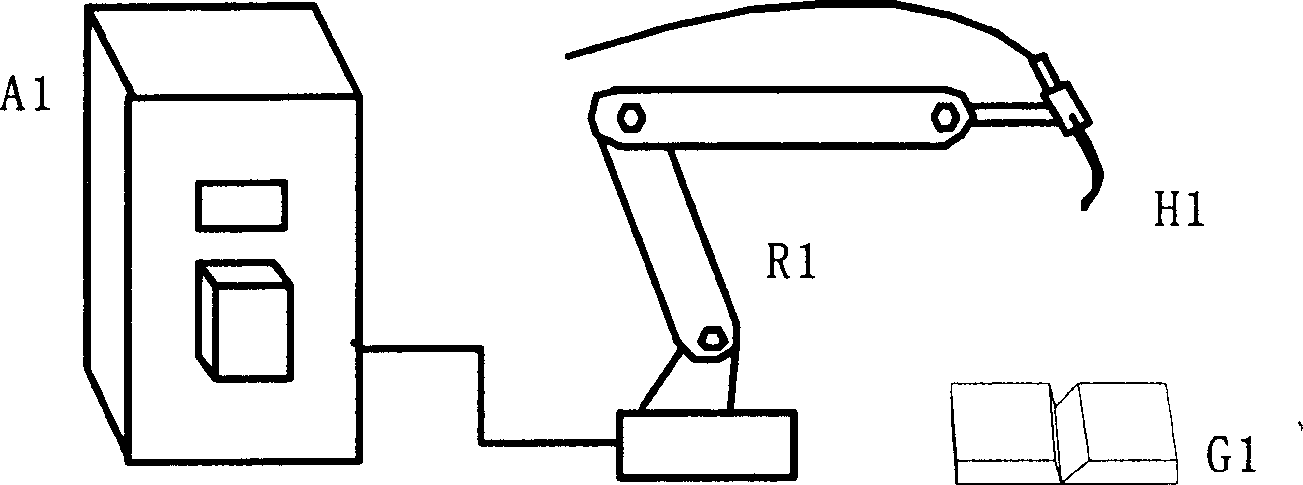

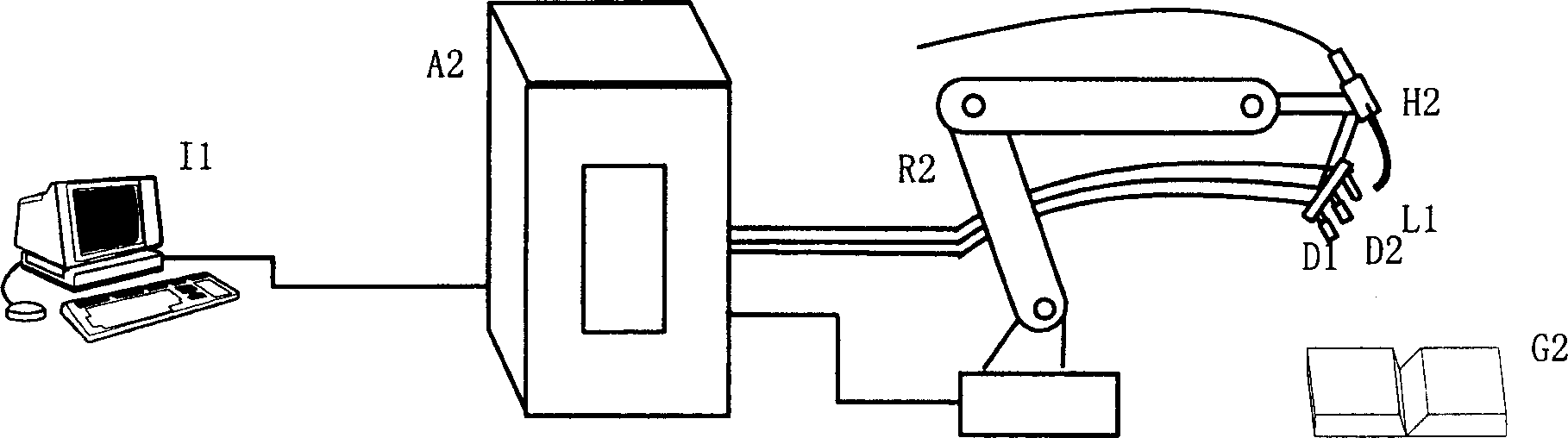

Arc welding robot control platform with visual welding seam automatic tracing function

An automatic tracking and control platform technology, applied in the direction of arc welding equipment, manipulators, manufacturing tools, etc., can solve problems such as imperfection, lack of openness, and inability to meet the requirements of robot identification and problem handling, and achieve the goal of improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

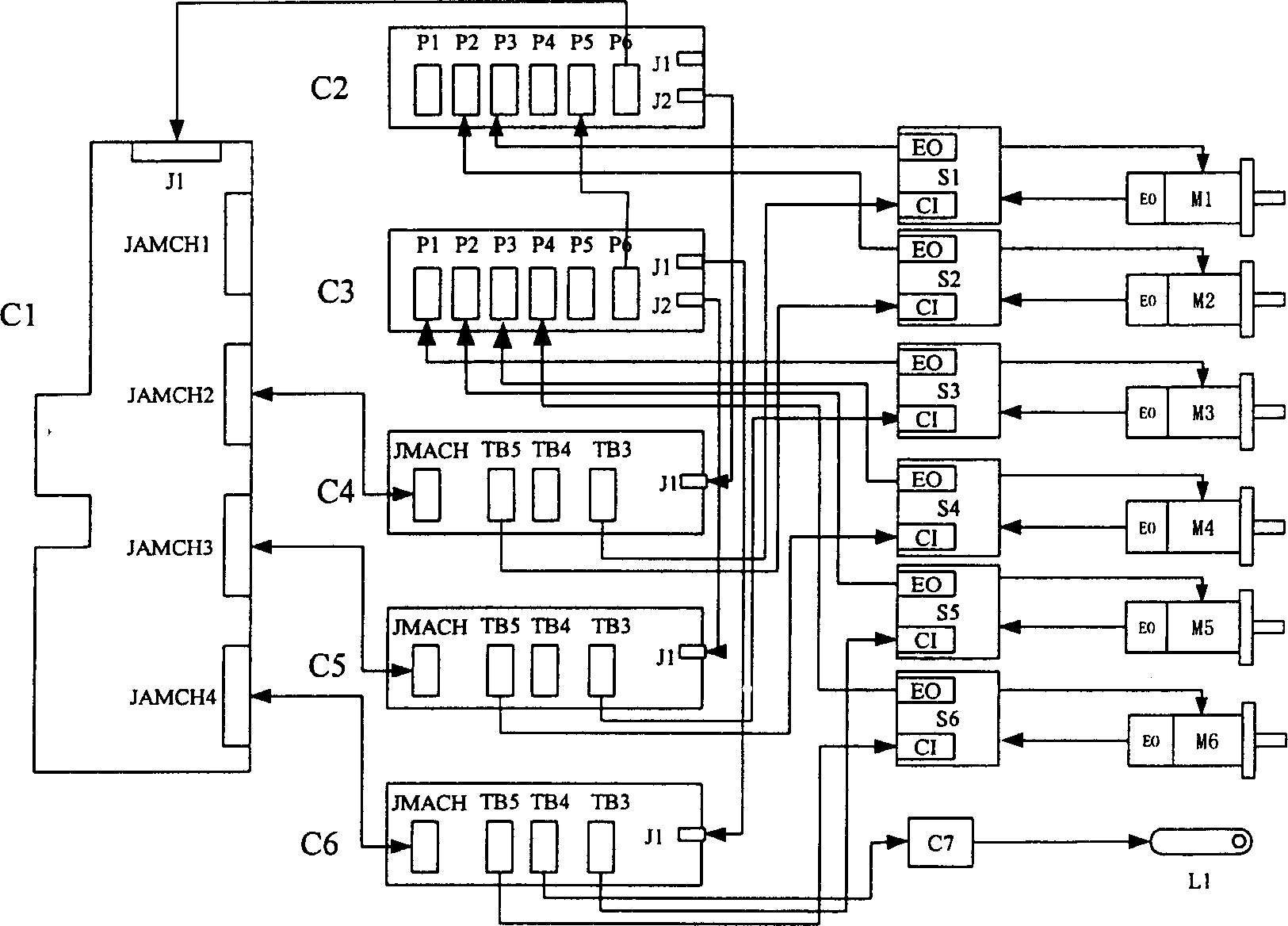

[0029] The control platform through image 3 The circuit shown implements the control of the robot's servo motor, adjustable laser. In the embodiment, an arc welding robot vision platform with visual welding seam automatic tracking function consisting of an industrial robot, an open industrial robot controller, two CCD cameras, a video acquisition card and a laser is built . The industrial computer can use ADVANTECH-610, and the Yaskawa YASKAWA MOTOMAN SK10 robot body can be used as the control object, and the servo package can use the Yaskawa YASKAWA CACR-SR15SZ1SD-Y214 single-axis drive servo package, which is used to drive the S, L, U of the robot. , R, B and T six joints, the camera adopts SONY Digital Hyper HAD color camera (additional filter can be added), the video acquisition card adopts PCI bus OK-C80 / M acquisition card, the laser adopts semiconductor laser (additional filter piece).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com