Irregular ceramic product rolling press forming machine

A rolling forming machine and special-shaped technology, which is applied in the field of ceramic machinery, can solve problems such as distortion, high labor intensity, and cracking, and achieve the effects of increased compactness and yield, stable and reliable operation, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

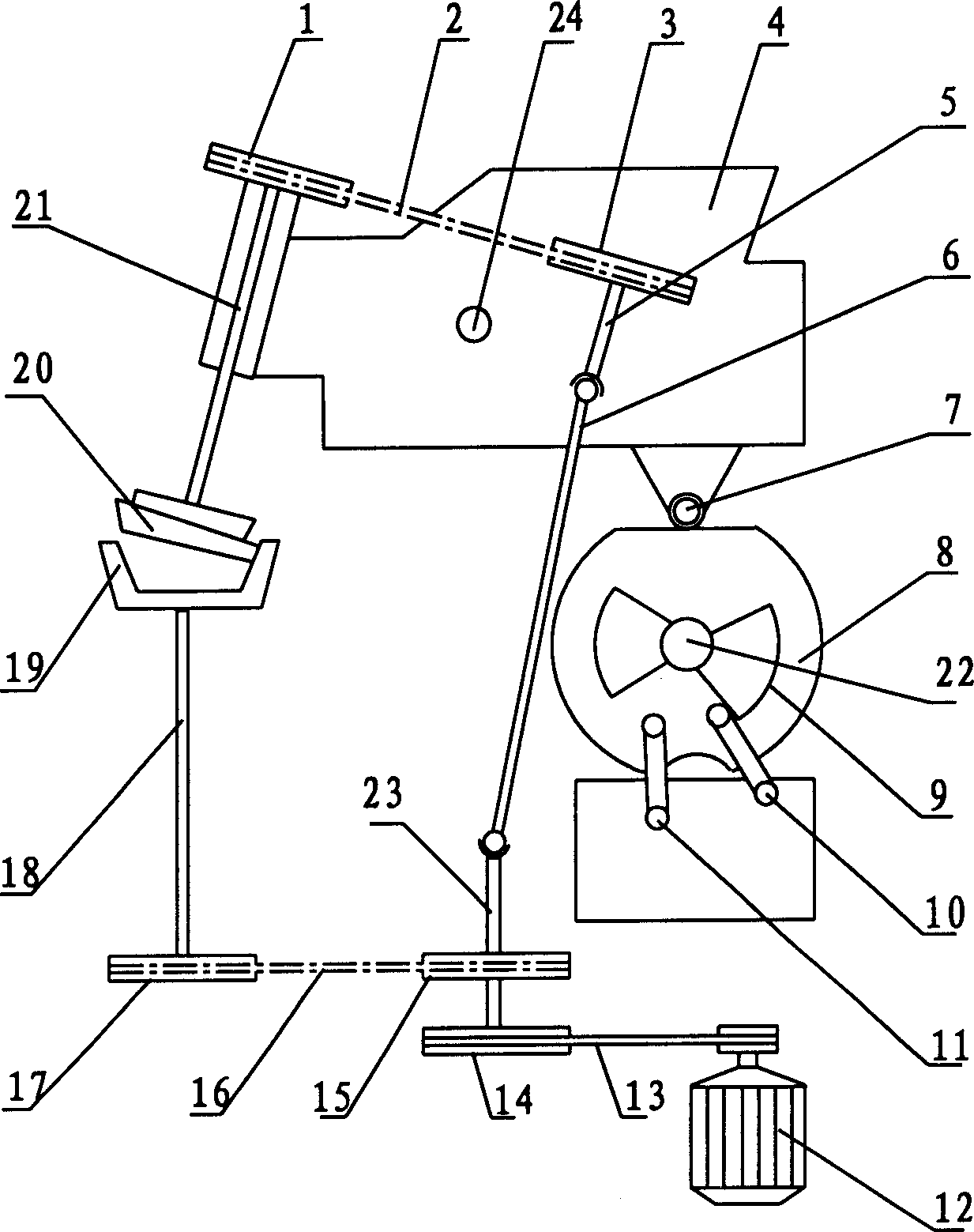

[0012] Such as figure 1 As shown, the roller head 20 matches the cavity of the model 19 and is shaped, and the shape of the model 19 is the same as that of the processed ceramic product. It can be a triangle, a square, a rounded square, a pentagon, etc. Irregular shape of the body of revolution. When processing ceramic products, the roller head 20 is placed in the model 19, and clay is put into the cavity between the roller head 20 and the model 19.

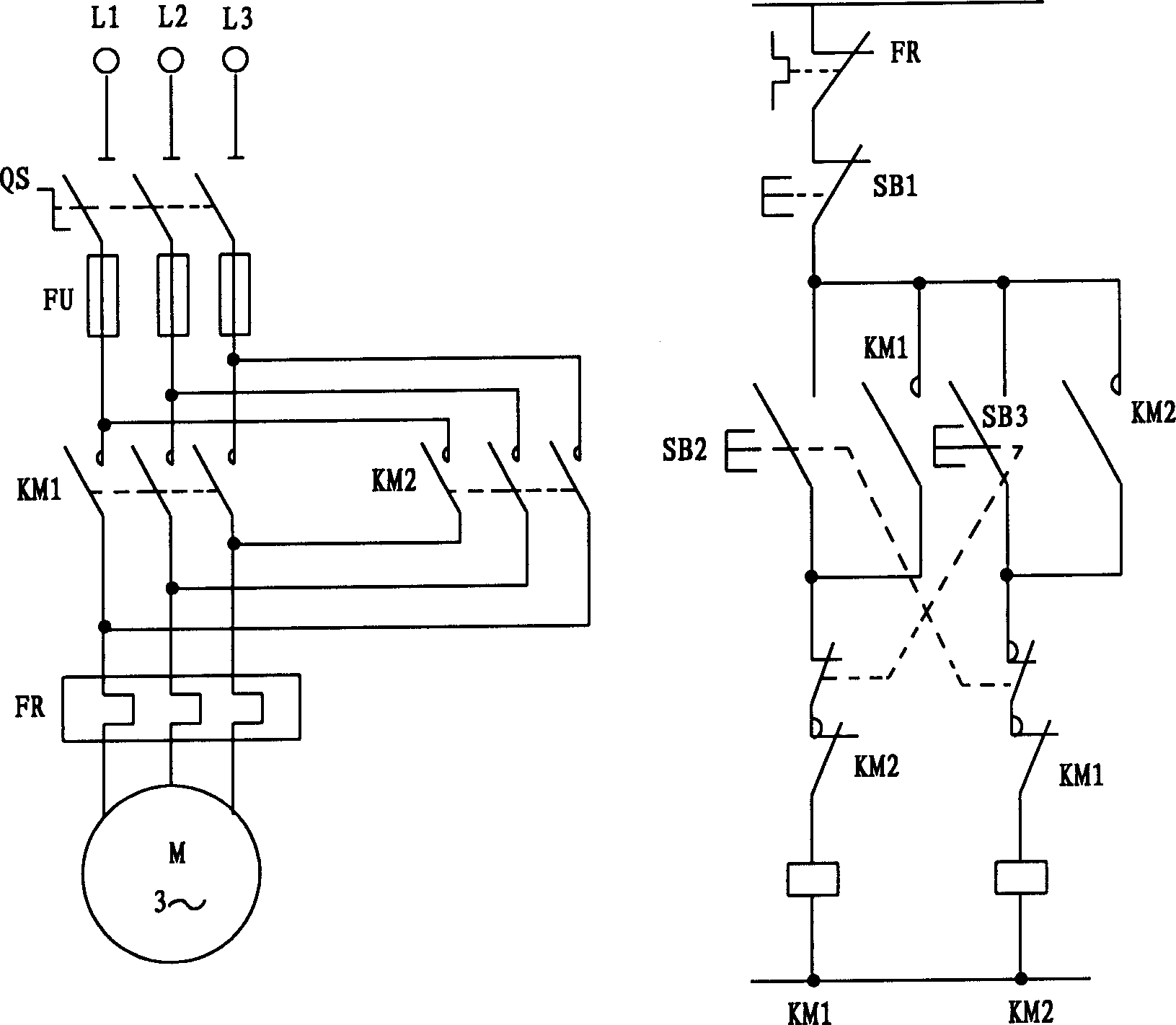

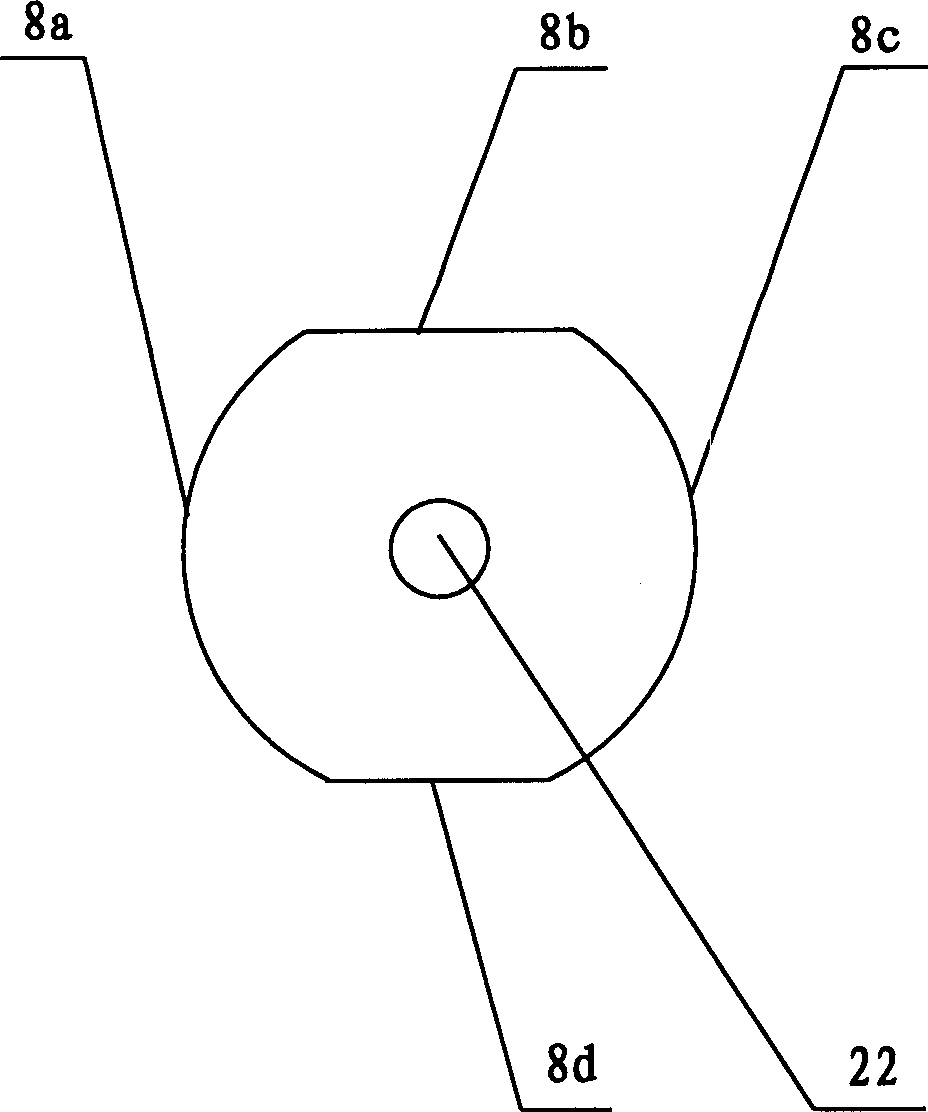

[0013] The cam 8 is driven by the motor to rotate, the roller 7 rolls along the contour surface of the cam 8, the dial 9 rotates synchronously with the cam 8, the dial 9 toggles the reversing switch 10, and the reversing switch 10 presses the motor forward rotation control button SB2 Closed, KM1 is opened, KM2 is closed and energized, and the motor 12 rotates forward. Motor 12 drives belt pulley 14 to rotate by belt 13, and belt pulley 14 drives sprocket wheel 15 to rotate by shaft, then drives sprocket wheel 17 to rotate by ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com