Microcapsule coated phase change material and its preparation method

A technology of phase change materials and microcapsules, which is applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., to achieve the effect of comfortable indoor environment, convenient operation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

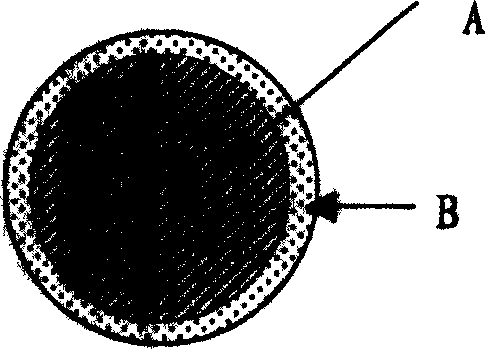

Image

Examples

Embodiment 1

[0047] (1) Emulsification of core material

[0048] Add 0.8g of NaOH, 5.3g of dispersant styrene maleic anhydride and 0.2g of emulsifier NP-10 into 100mL of deionized water as a dispersion medium, and hydrolyze for 2 hours at 30-50°C to make the pH = 4.5, then add 32g of core material phase change material lauryl alcohol, mechanically stir at a speed of 1000r / min, and emulsify for 10min, so that the dispersed particle size of the core material reaches 10-20 μm, and the core material emulsion is obtained.

[0049] (2) Preparation of wall material prepolymer

[0050] Add 20 g of 37% formaldehyde aqueous solution and 50 g of deionized water to 20 g of melamine, adjust the pH to 8, heat to 70° C., and keep warm for 2 hours to prepare a melamine-formaldehyde prepolymer aqueous solution.

[0051] (3) The first layer of cladding of the wall material

[0052] Divide the melamine-formaldehyde prepolymer aqueous solution prepared above into 2 equal parts for later use; then pour the h...

Embodiment 2

[0059] (1) Emulsification of core material

[0060] Add 0.8g of NaOH, 5.3g of dispersant ethylene maleic anhydride and 0.2g of emulsifier NP-10 into 100mL of deionized water as a dispersion medium, and hydrolyze it for 2 hours at 30-50°C to make it pH = 4, then add 32g of core material phase change material lauryl alcohol, mechanically stir at a speed of 2000r / min, and emulsify for 2min, so that the dispersed particle size of the core material reaches 1-5 μm, and the core material emulsion is obtained.

[0061] (2) Preparation of wall material prepolymer

[0062] Add 20 g of 37% formaldehyde aqueous solution and 50 g of deionized water to 20 g of melamine, adjust the pH to 8, heat to 70° C., and keep warm for 2 hours to prepare a melamine-formaldehyde prepolymer aqueous solution.

[0063] (3) The first layer of cladding of the wall material

[0064] Divide the melamine-formaldehyde prepolymer aqueous solution prepared above into 2 equal parts for later use; then pour the hom...

Embodiment 3

[0071] (1) Emulsification of core material

[0072] Add 0.96g of NaOH, 6.4g of dispersant styrene maleic anhydride and 0.2g of emulsifier NP-10 into 100mL of deionized water as a dispersion medium, and hydrolyze for 2 hours under the condition of 30-50°C to make the pH = 5. Add 32g of core material phase change material lauryl alcohol, stir mechanically at a speed of 2000r / min, and emulsify for 8 minutes, so that the dispersed particle size of the core material reaches 1-5 μm, and the core material emulsion is prepared.

[0073] (2) Preparation of wall material prepolymer

[0074] Add 20 g of formaldehyde aqueous solution and 50 g of water to 20 g of melamine, adjust the pH to 8, heat to 70° C., and keep warm for 2 hours to prepare a melamine-formaldehyde prepolymer aqueous solution.

[0075] (3) The first layer of cladding of the wall material

[0076] Divide the melamine-formaldehyde prepolymer aqueous solution prepared above into 2 equal parts for later use; then pour the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com