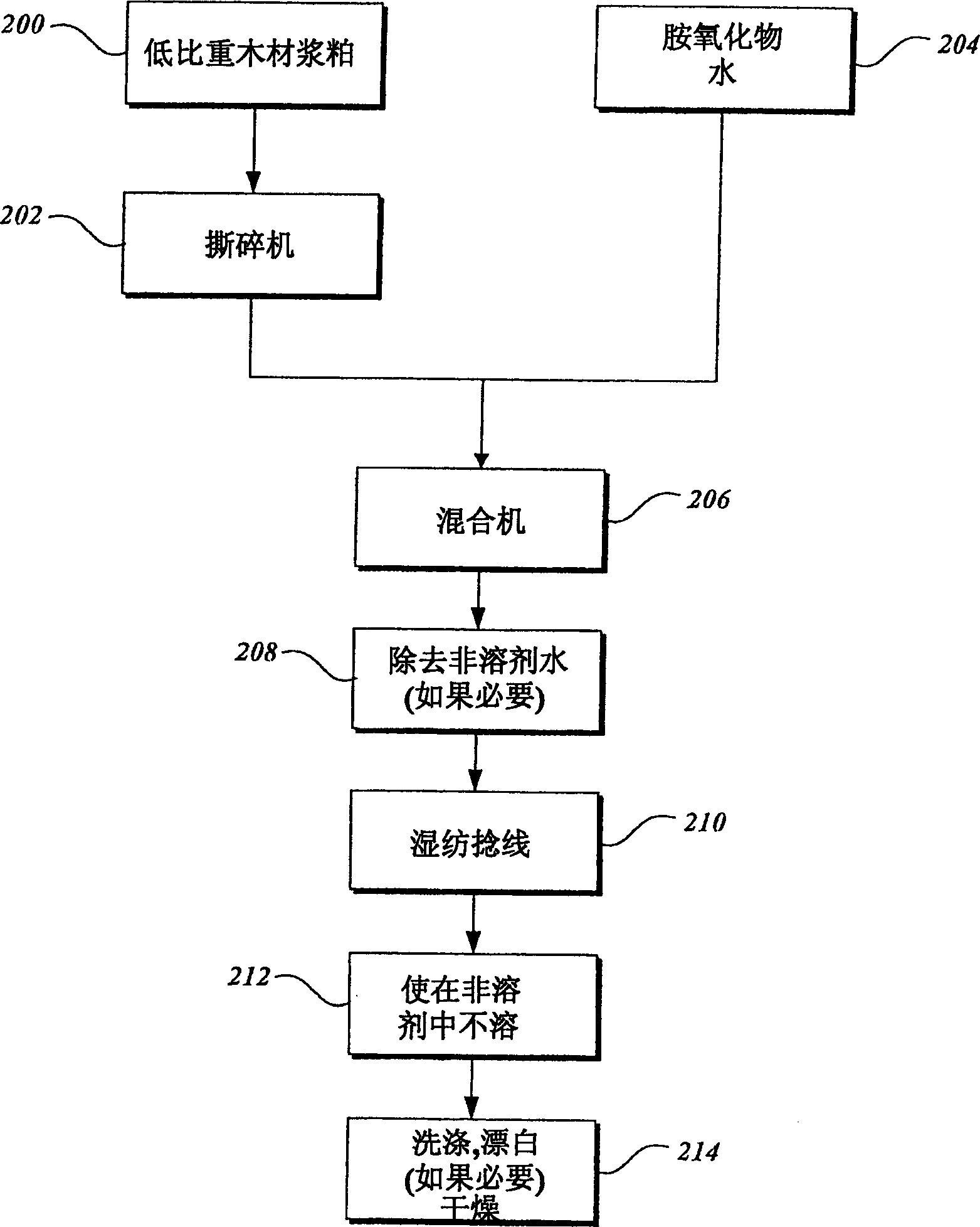

Thinning wood and other low specific wood used for leiser pomace

A technology of pulp and content, applied in the direction of pulping with inorganic alkali, synthetic cellulose/non-cellulose material pulp/paper, pulp bleaching, etc., can solve the problem of unutilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

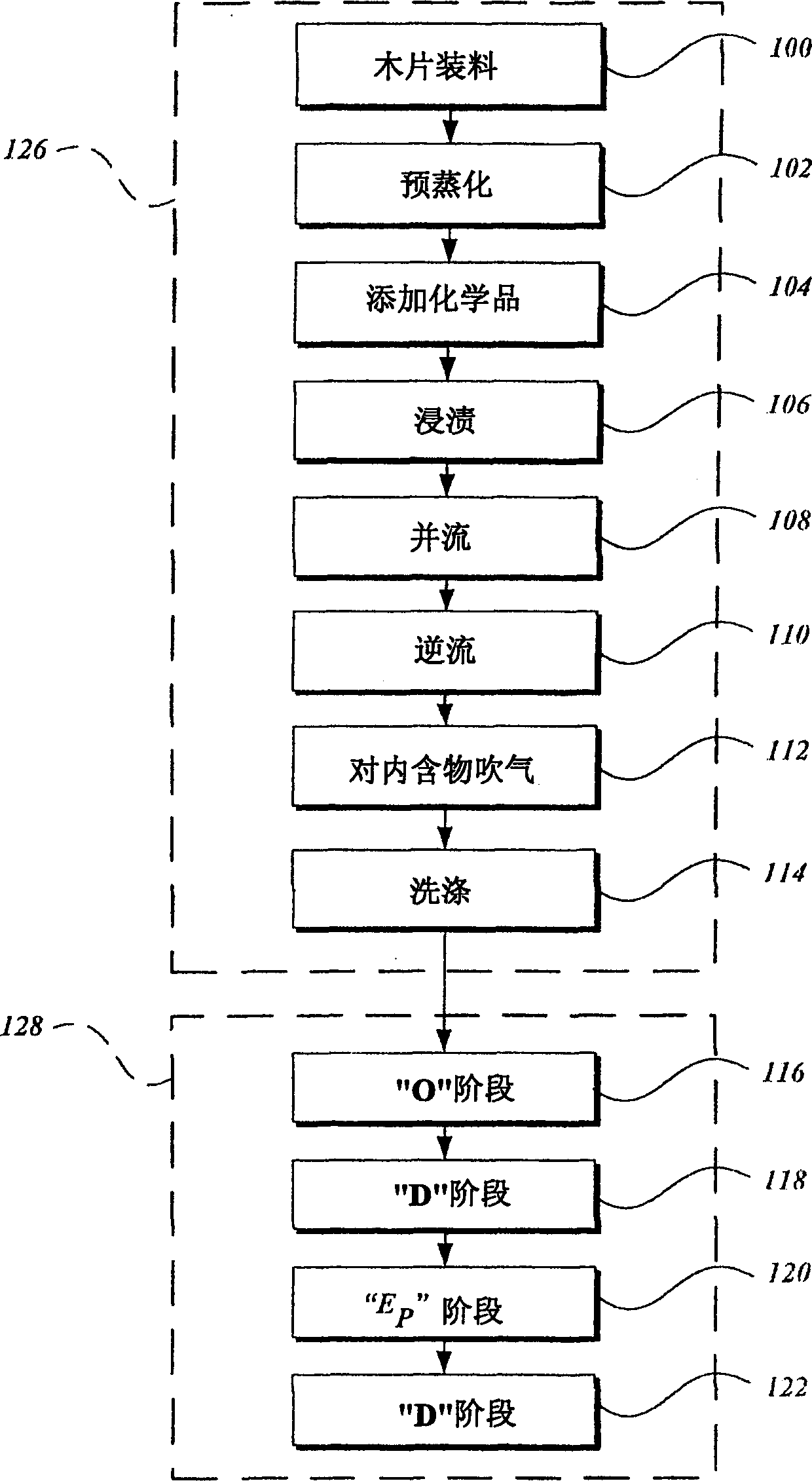

[0059] A commercial continuous extension lignification process is simulated in the laboratory using a specially constructed reactor vessel with associated auxiliary equipment including circulation pumps, batteries and direct heat exchangers. The temperature of the reactor was controlled by indirect heating and continuous circulation of cooking liquor. A standard amount of wood without equivalent moisture content was charged to the reactor vessel. An atmospheric pre-steaming step may optionally be performed prior to cooking. The cooking liquor and dilution water are then added to the digester to achieve the target liquor / wood ratio, wherein the cooking liquor is added in an amount of about 50% to 80% of the total cooking liquor. The reactor is then brought to the impregnation temperature and pressure and held for the target time. After the steeping process, about 5% to 15% of the total amount of cooking liquor is then added to the reactor vessel. The reactor was then brought...

Embodiment 2

[0062] Pulping Process Parameters for Low Specific Gravity Wood

[0063] A primary cook for low specific gravity wood chips has the following parameters.

[0064] Wood chips S.G.

Embodiment 3

[0066] Bleaching of low specific gravity wood

[0067] The pulp produced by the method of Example 2 was bleached according to the following procedure.

[0068] Phase O

[0069] Inwoods low specific gravity wood chips were pulped to form alkaline kraft pulp (TAPPI standard T236 cm-85 with a viscosity of 239 cP (TAPPI T230)) with a kappa number of 16.8. Brownstock pulp is treated with oxygen in a pressure vessel with high consistency mixing capabilities. Preheat the vessel to about 120°C. Sodium hydroxide (NaOH) equivalent to 100 pounds per ton of pulp was added to the alkaline pulp. The reaction vessel was then closed and the pressure increased to 60 psig by introducing oxygen into the pressure vessel. Water is present in the container in an amount sufficient to provide a 10% consistency.

[0070] After 45 minutes, agitation was stopped and the pulp was removed from the pressure vessel and washed. The resulting washed pulp had a viscosity of 35.3 cP and a Kappa value of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com