Antibacterial material of molecular sieve containing zinc and its preparing method

An antibacterial material and molecular sieve technology, applied in botany equipment and methods, animal repellents, biocides, etc., can solve the problems of human body harm, silver-containing molecular sieves are easy to oxidize and discolor, expensive and copper-containing molecular sieves, etc., to achieve manufacturing The effect of low cost, reliable design parameters and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

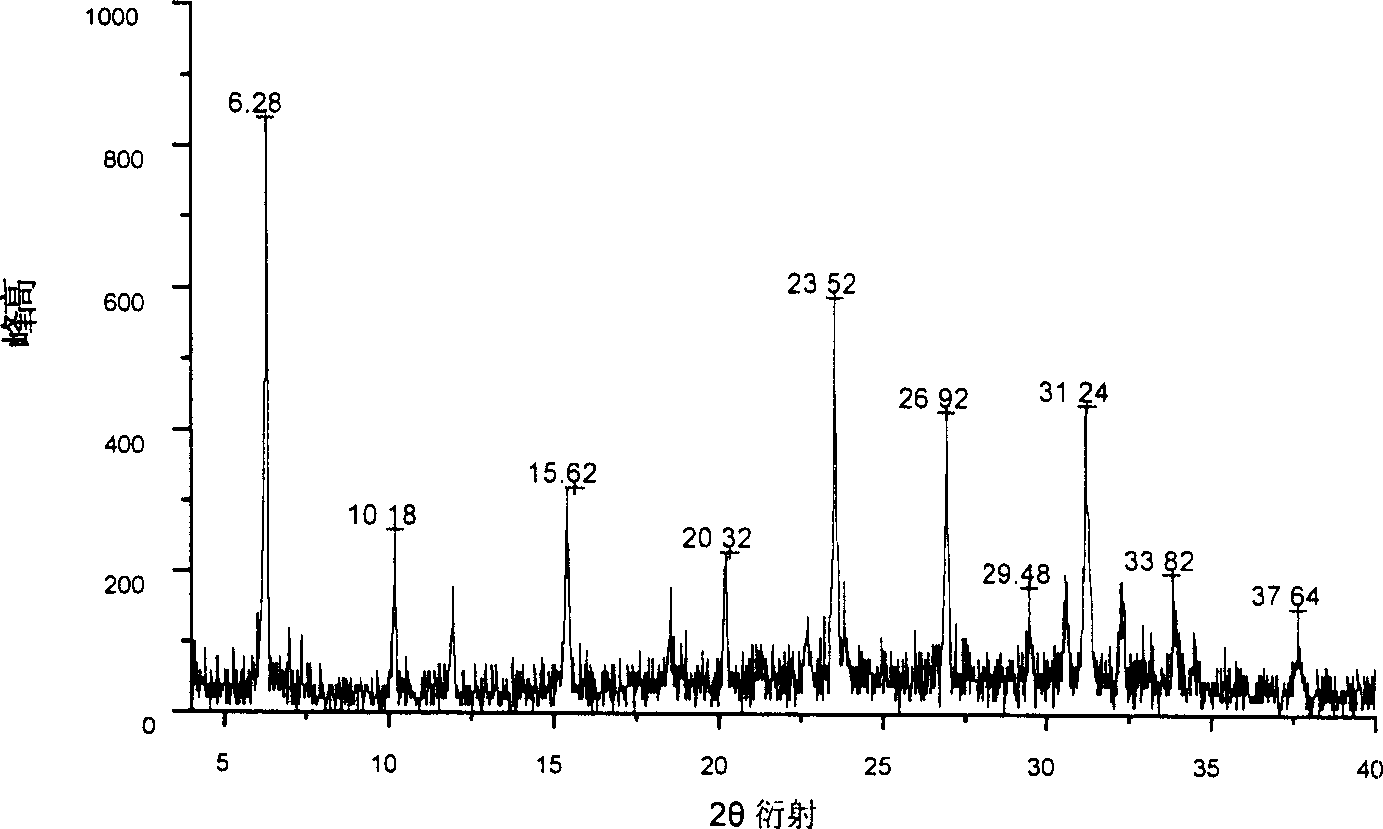

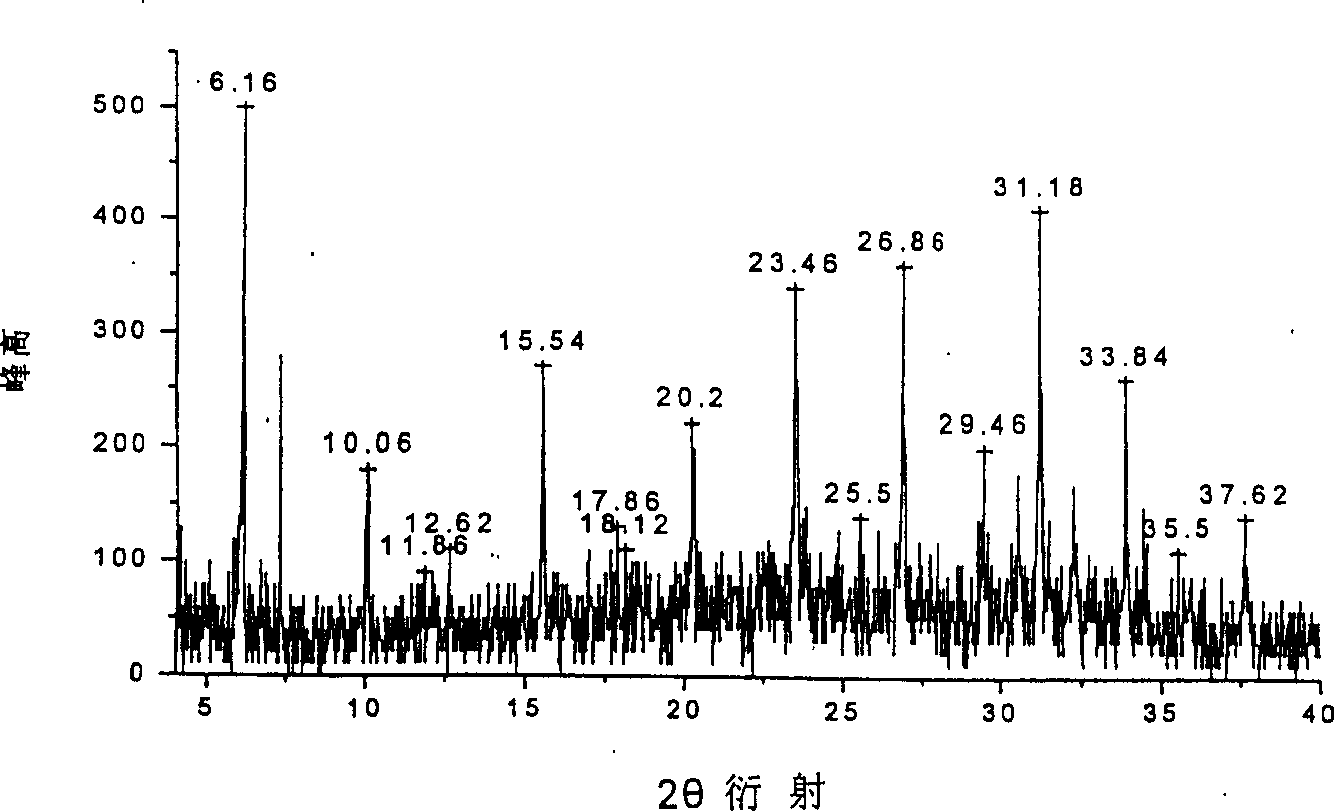

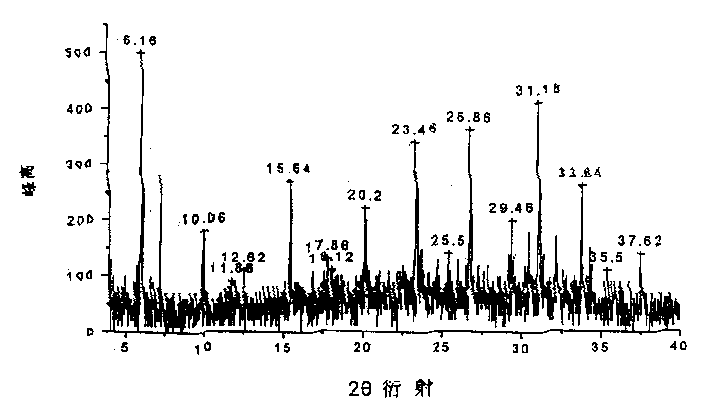

Image

Examples

Embodiment 1

[0039] The carrier of the antibacterial material is selected as X-type molecular sieve Na 2 O+Al 2 o 3 +(2.5±0.5)SiO 2 As a carrier, the zinc salt is zinc sulfate. The ratio of raw materials is as follows: the weight of zinc sulfate is 600g, the weight of molecular sieve is 100g, and the weight of water dispersant is 10000g.

[0040] Dissolve 600g of zinc salt in 10,000g of distilled water at room temperature to form a colorless solution. Add 100 g of molecular sieves, heat to 100° C., stir and reflux for 6 hours, cool to room temperature, filter with suction, wash with distilled water 6 times to remove surface ions, and dry in the air. That is, the zinc-containing molecular sieve antibacterial material is obtained, wherein the exchange degree of zinc ions and sodium ions is 85%. The antibacterial rate to Staphylococcus aureus and pathogenic Escherichia coli both reached 95%.

Embodiment 2

[0042] The carrier of the antibacterial material is selected as X-type molecular sieve Na 2 O+Al 2 o 3 +(2.5±0.5)SiO 2 As a carrier, the zinc salt is zinc sulfate. The ratio of raw materials is as follows: the weight of zinc sulfate is 300g, the weight of molecular sieve is 100g, and the weight of distilled water dispersant is 10000g.

[0043] Dissolve 300g of zinc salt in 10,000g of distilled water at room temperature to form a colorless solution. And add 100g of molecular sieves, heat to 95°C, stir and reflux for 3 hours, cool, filter with suction, wash with distilled water 6 times to remove surface ions, and dry in the air. That is, the zinc-containing molecular sieve antibacterial material is obtained, wherein the exchange degree of zinc ions and sodium ions is 75%, and the antibacterial rates against Staphylococcus aureus and pathogenic Escherichia coli both reach 85%.

Embodiment 3

[0045] The carrier of antibacterial materials is B-type (4A), also known as sodium A-type; the chemical composition is Na 2 O+Al 2 o 3 +2SiO 2 Molecular sieve with a pore size of 0.4nm.

[0046] The ratio of zinc sulfate:molecular sieve:distilled water is 3:1:100.

[0047] Dissolve 300g of zinc salt in 10,000g of distilled water at room temperature to form a colorless solution. And add 100g molecular sieve, heat to 90°C, stir and reflux for 4 hours, cool, filter with suction, wash 6 times with distilled water, wash away surface ions, and dry to obtain zinc-containing molecular sieve antibacterial material, wherein the exchange of zinc ions and sodium ions The degree is 80%. The antibacterial rate to Staphylococcus aureus and pathogenic Escherichia coli both reached 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com