Mixing power driven semi-mounted type lorry

A hybrid, power-driven technology, applied in the field of transportation trucks, can solve the problems of high price, restricting the development of high-speed heavy vehicles, and consuming foreign exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

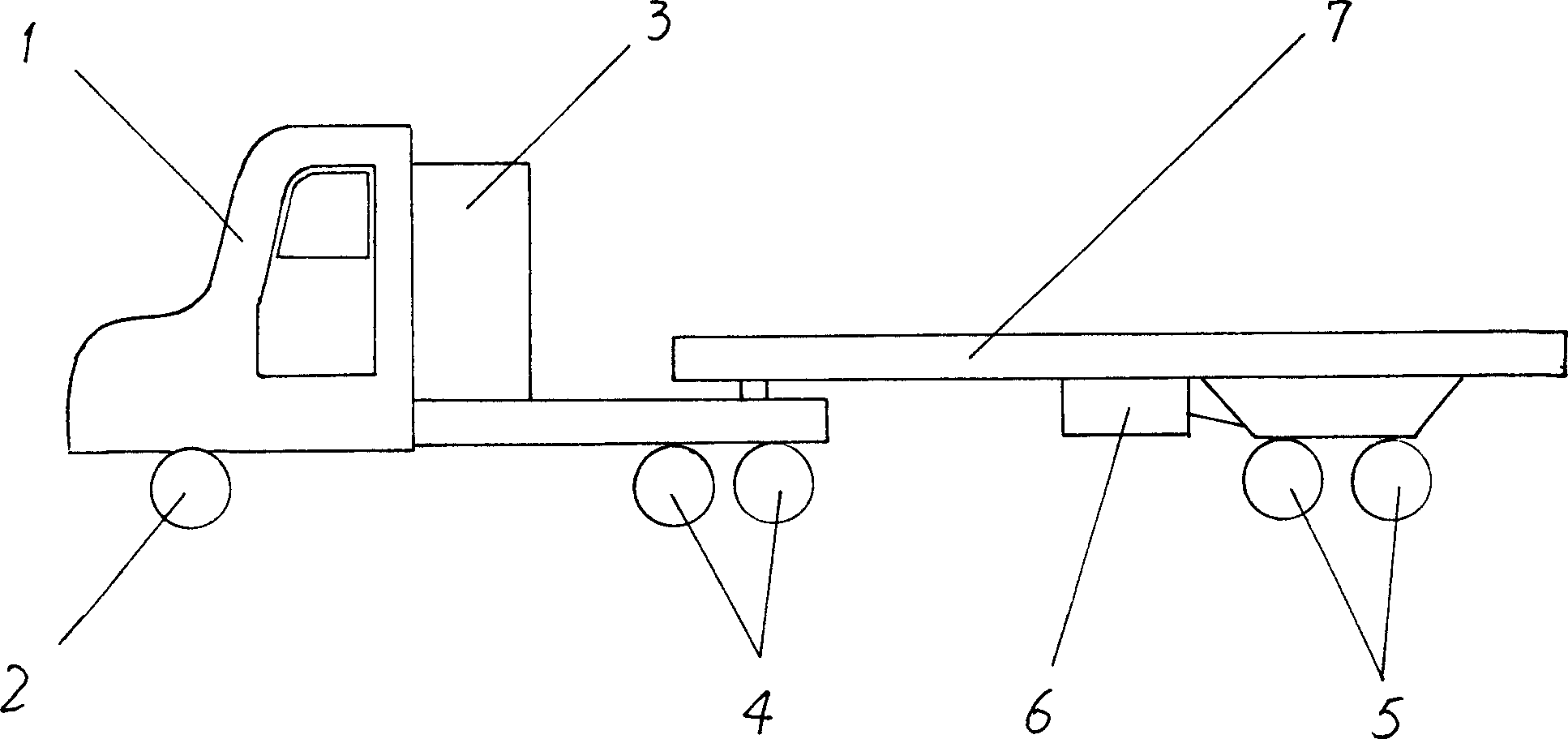

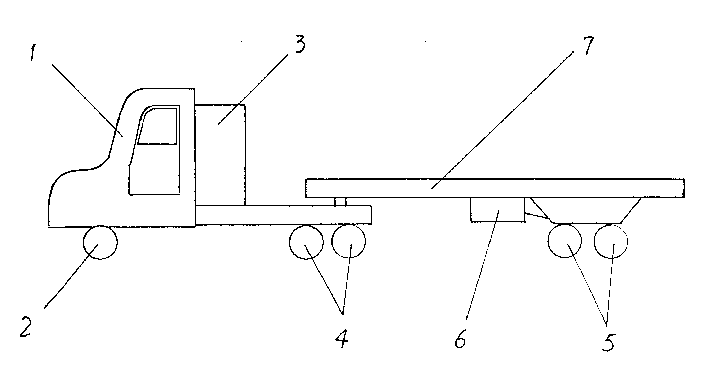

[0017] A 130KW (175 horsepower) engine and a matching gearbox are refitted on the original 260KW (350 horsepower) traction main vehicle 1, and a 130KW generator set 3 is installed at the rear of the cab. A drive motor 6 of 130KW is installed on the rear axle 5 of 7, and is electrically connected with generator set 3. The result is a hybrid-powered semi-truck that still packs 350 horsepower. The centralized driving of the semi-trailer vehicle to tow the main vehicle is an evenly distributed driving of the whole vehicle, which improves the driving characteristics and improves the driving efficiency. And because the domestic 130KW engine can be used, compared with the original 350-horsepower semi-trailer truck that can only be imported with a 260KW engine and gearbox, its production cost can be reduced by more than 100,000 yuan, and the economy of the vehicle operation can be reduced. There is a substantial increase.

[0018] In addition, more than two on-board generator sets c...

Embodiment 2

[0020] On the semi-trailer trucks with front and rear drives that retain the existing mechanical power drive system, one is to install an electric drive system on the semi-trailer 7, and the other is to change the front axle 2 on the traction main vehicle 1 to an electric drive. Drive, or retain the transfer case, on the basis of mechanical transmission, install the auxiliary drive motor for the front axle 2, and install the auxiliary motor on the transmission shaft or drive axle 4 of the traction main vehicle 1. In this way, the semi-trailer vehicle becomes an all-wheel drive in a complete sense, and then the driving state of each axle or each wheel is regulated by using the existing technical means, which can greatly improve the passing performance and running performance of the vehicle, and save fuel. The effect is remarkable.

Embodiment 3

[0022] Keep the main part of the above-mentioned hybrid drive semi-trailer truck unchanged, but change the power drive device on the traction main vehicle 1 to a drive motor installed on the drive axle 4, and the drive motor is electrically connected to the on-board generator set 3 . In this way, the vehicle is driven entirely by electric motors, thereby eliminating the gearbox and transfer case. The electric drive system can drive individual axles or wheels of the vehicle, and can also drive all axles or wheels, so that the working efficiency of the drive system is improved. In this vehicle, since there are two processes of power generation and electric drive, it also belongs to the working mode of hybrid power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com