Method for producing a positive electrode active material for an alkaline storage battery

A positive active material and storage battery technology, which is applied in the direction of alkaline battery electrodes, electrode manufacturing, battery electrodes, etc., and can solve problems such as battery capacity decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] (1) active substance

[0092] active substance (a)

[0093] (i) Step 1

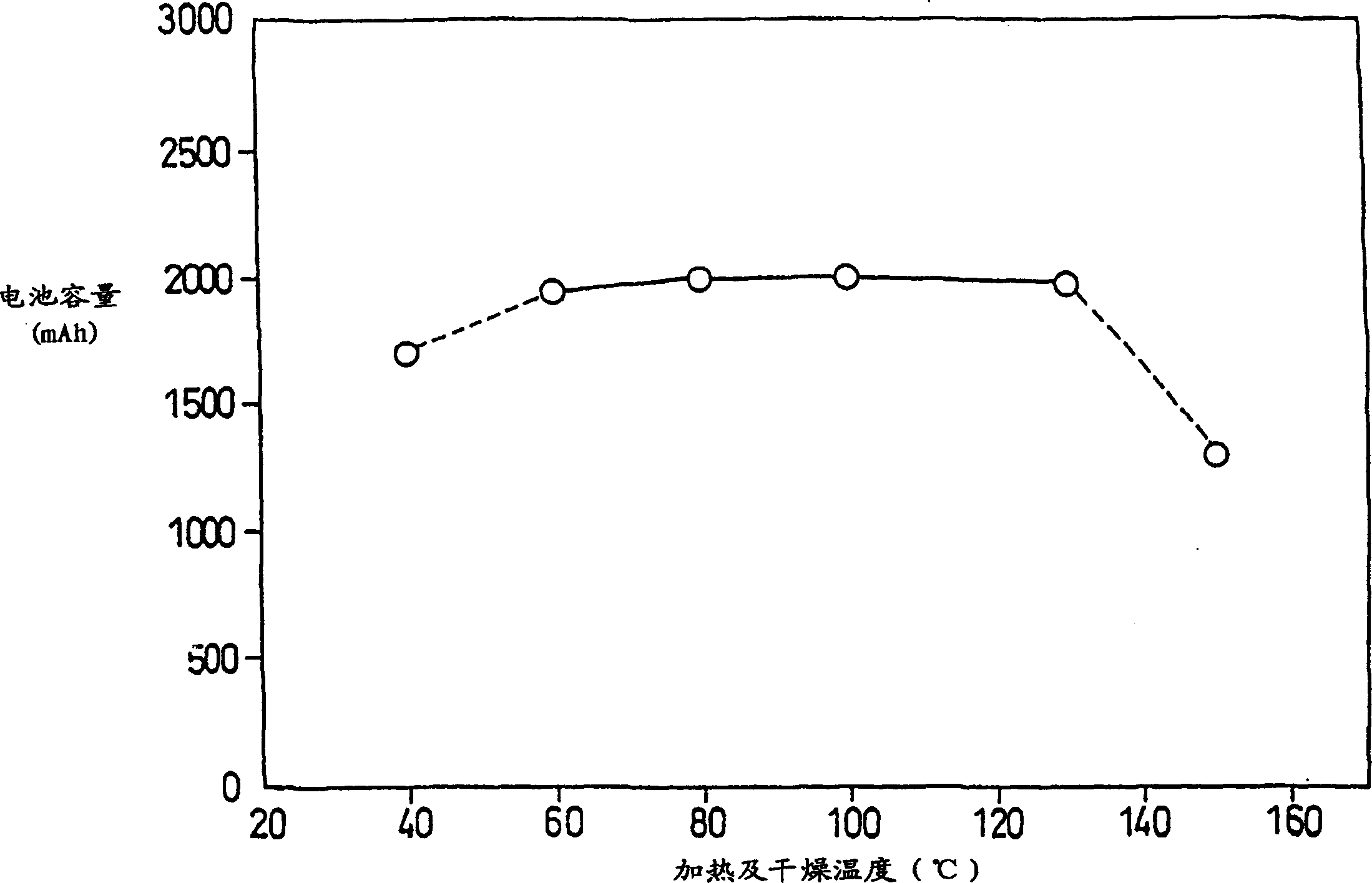

[0094] A raw material powder in which 5 parts by weight of cobalt hydroxide was adhered to the surface of 100 parts by weight of nickel hydroxide solid solution powder (average particle diameter: 10 μm) containing 3% by weight of magnesium was prepared. 8 ml of a 18N sodium hydroxide aqueous solution was added to 100 g of the aforementioned powder, and microwaves were irradiated while blowing in heated air at 100°C. Continue stirring the powder during this time. Then, the temperature of the powder was maintained at 100° C., and the powder was dried while controlling the humidity. The obtained dried powder was washed with water and dried to obtain nickel hydroxide solid solution powder having cobalt oxyhydroxide on the surface. The resulting powder exhibited a compact conductivity of about 0.1 S / cm. In addition, the oxidation value of cobalt determined by iodine titration was 3.19.

[0095] (i...

Embodiment 2

[0149] Elements contained in nickel hydroxide solid solution powder were studied. That is, the nickel hydroxide solid solution containing Mg is replaced with a nickel hydroxide solid solution containing Co, Zn, Cd, Ca, Sr, Mn, Al, Co and Zn, or Co and Mg. For example, when Al is included, the raw material powder having 5 parts by weight of cobalt hydroxide attached to the surface of 100 parts by weight of nickel hydroxide solid solution powder (average particle diameter of 10 μm) containing 3% by weight of aluminum element is used to obtain a surface with cobalt oxyhydroxide. of nickel oxyhydroxide. In addition, according to the battery (a-1) of the embodiment of the same operating sequence to prepare the battery, its discharge capacity C 0.4 and capacity retention (C 500 / C ini ×100) was also measured in the same manner as battery (a-1). The obtained results are shown in Table 2.

[0150] For comparison, the active material (a) was replaced by nickel hydroxide powder, an...

Embodiment 3

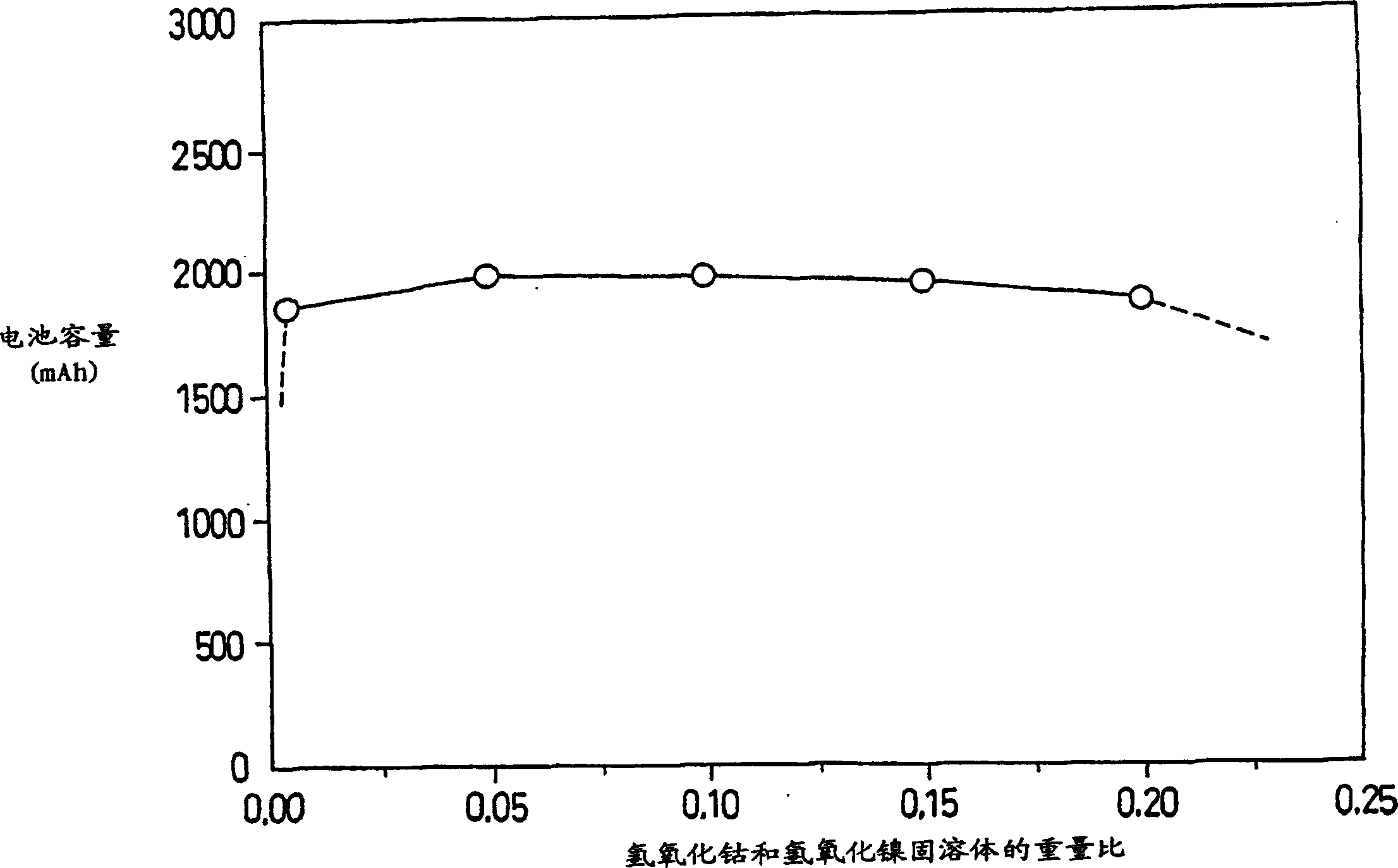

[0154] The weight ratio of cobalt hydroxide and nickel hydroxide solid solution powders was studied. Except changing the mixing ratio of nickel hydroxide solid solution powder and cobalt hydroxide powder, other operations are the same as active material (b), and various active materials are prepared. A battery similar to battery (b-1) was produced using these active materials. Then, measure the battery capacity C at a discharge current value of 0.4A in the same manner as battery (b-1). 0.4 .

[0155] The relationship between the weight ratio of cobalt hydroxide and nickel hydroxide solid solution and the battery capacity is as follows figure 1 shown.

[0156] figure 1 It shows that when the weight ratio of cobalt hydroxide and nickel hydroxide solid solution powder is in the range of 0.005 to 0.2, stable battery capacity can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com