Oil rapid fire extinguishing agent

A fire extinguishing agent and rapid technology, applied in fire protection equipment and other directions, can solve the problems of long-term re-ignition, low solubility, weak hydrophilicity, etc., and achieve fine and uniform foam, good chemical stability, and good re-ignition resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An oil rapid fire extinguishing agent, mainly composed of the following components:

[0025] C 6 f 13 SO 2 NH(CH 2 ) 3 N(CH 3 )CONH 2 3.5%

[0026] F[C(CF 3 )FCF 2 O]nC(CF 3 )FCONH(CH 2 ) 3 NO(C 2 h 5 ) 2 (n=1-2) 3.0%

[0027] Coconut Betaine 15%

[0028] Hydrolyzed Animal Protein 4%

[0029] Sodium 2-Ethylhexyl Sulfate 10%

[0030] Xanthan Gum 0.5%

[0031] Water 63%

Embodiment 2

[0033] An oil rapid fire extinguishing agent, mainly composed of the following components:

[0034] C 6 f 13 SO 2 NH(CH 2 ) 3 N(CH 3 )CONH 2 2.5%

[0035] F[C(CF 3 )FCF 2 O]nC(CF 3 )FCONH(CH 2 ) 3 NO(C 2 h 5 ) 2 (n=1-2) 2.5%

[0036] Coconut Betaine 15%

[0037] Hydrolyzed Animal Protein 5%

[0038] Sodium 2-Ethylhexyl Sulfate 10%

[0039] Lemon Pectin 1%

[0040] Water 64%

Embodiment 3

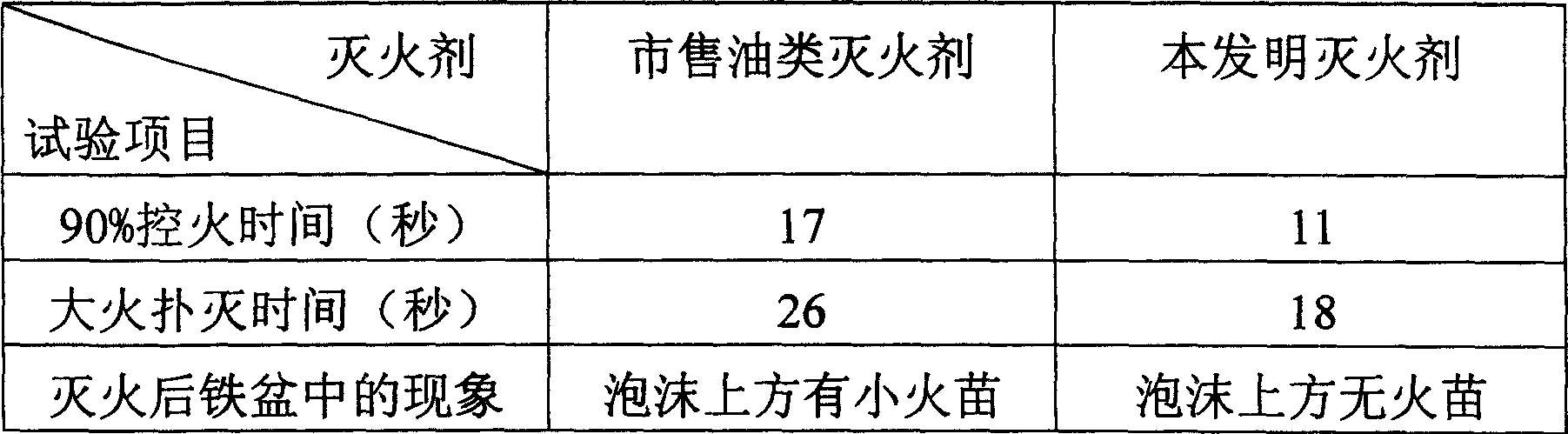

[0042] The present invention carries out fire extinguishing test comparison with commercially available oily fire extinguishing agent (as strengthened water), all with 6 liters of portable foam fire extinguishers as test samples. Add 35 liters of 90# gasoline into the garden iron basins with a diameter of 1.2 meters respectively, ignite the gasoline, and start to extinguish the fire after burning for 1 minute. The results of the test are shown in the table below.

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com